Design Example: Aluminum Extrusion Structures¶

CAD rendering of 15 mm aluminum extrusion with various joining plates.¶

This example demonstrates parts useful for rapidly assembling structures using T-slotted aluminum extrusion. The examples are sized for 15 mm square extrusion with slots which accept an M3 nut. The various joining plates can be clamped against any face of the extrusion using M3 screws which engage nuts placed within the slots. The fasteners can slide along the slot to the desired position and then clamp down to form a robust frictional connection.

The SolidWorks model files and individual DXF cutting files may be found in the extrusion-connectors/ folder, or may be downloaded as a single file as extrusion-connectors.zip.

Typically these parts are laser-cut from 3 mm plywood. The holes are sized for a loose fit on an M3 screw. The joining plate hole patteners use a standard 15 mm spacing.

T Slot Connection¶

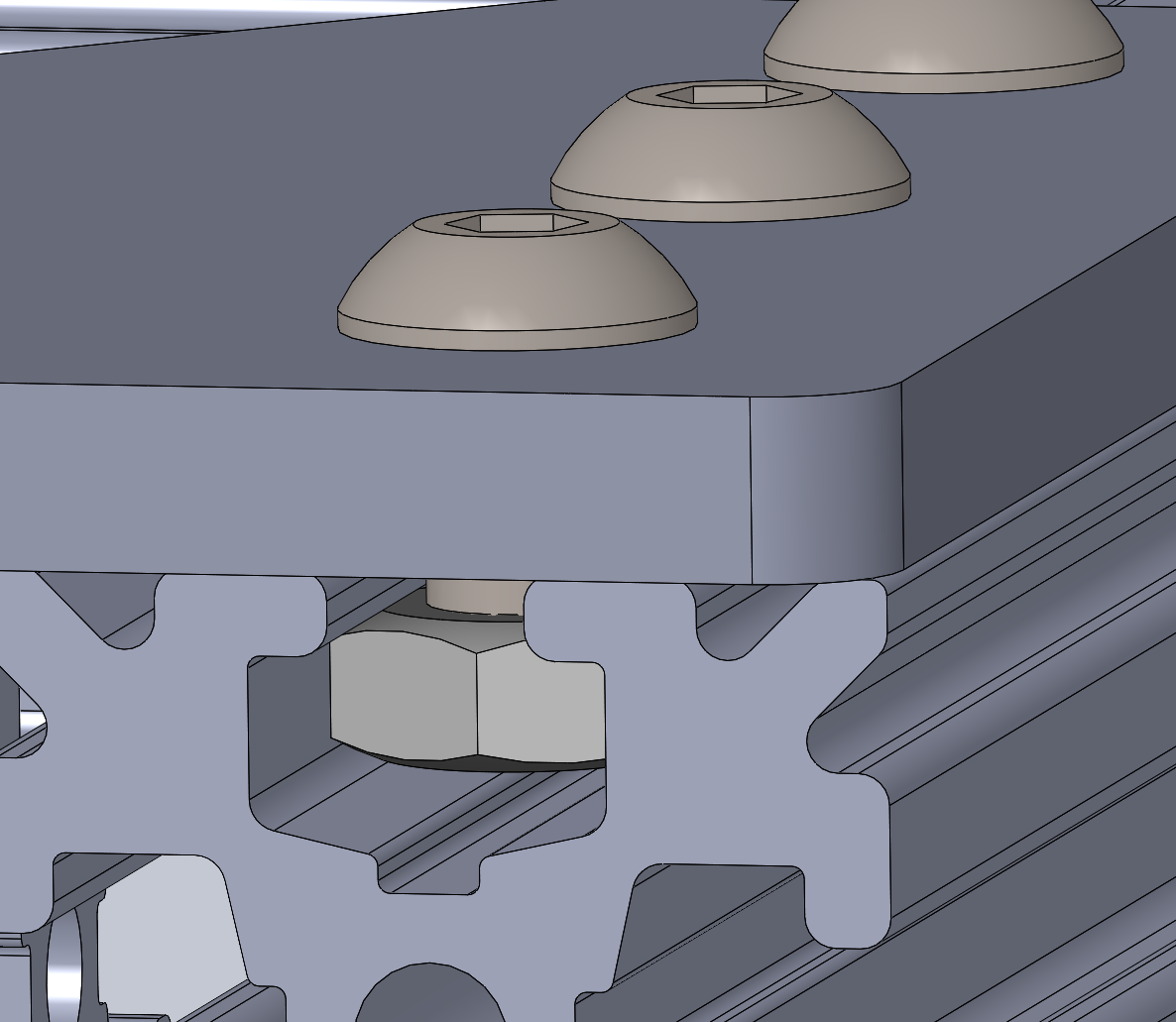

Detail of the slot connection. A captive M3 nut fits loosely in the slot without freely rotating. The M3 x 6 screw engages the nut to clamp the joining plate against the extrusion face.¶

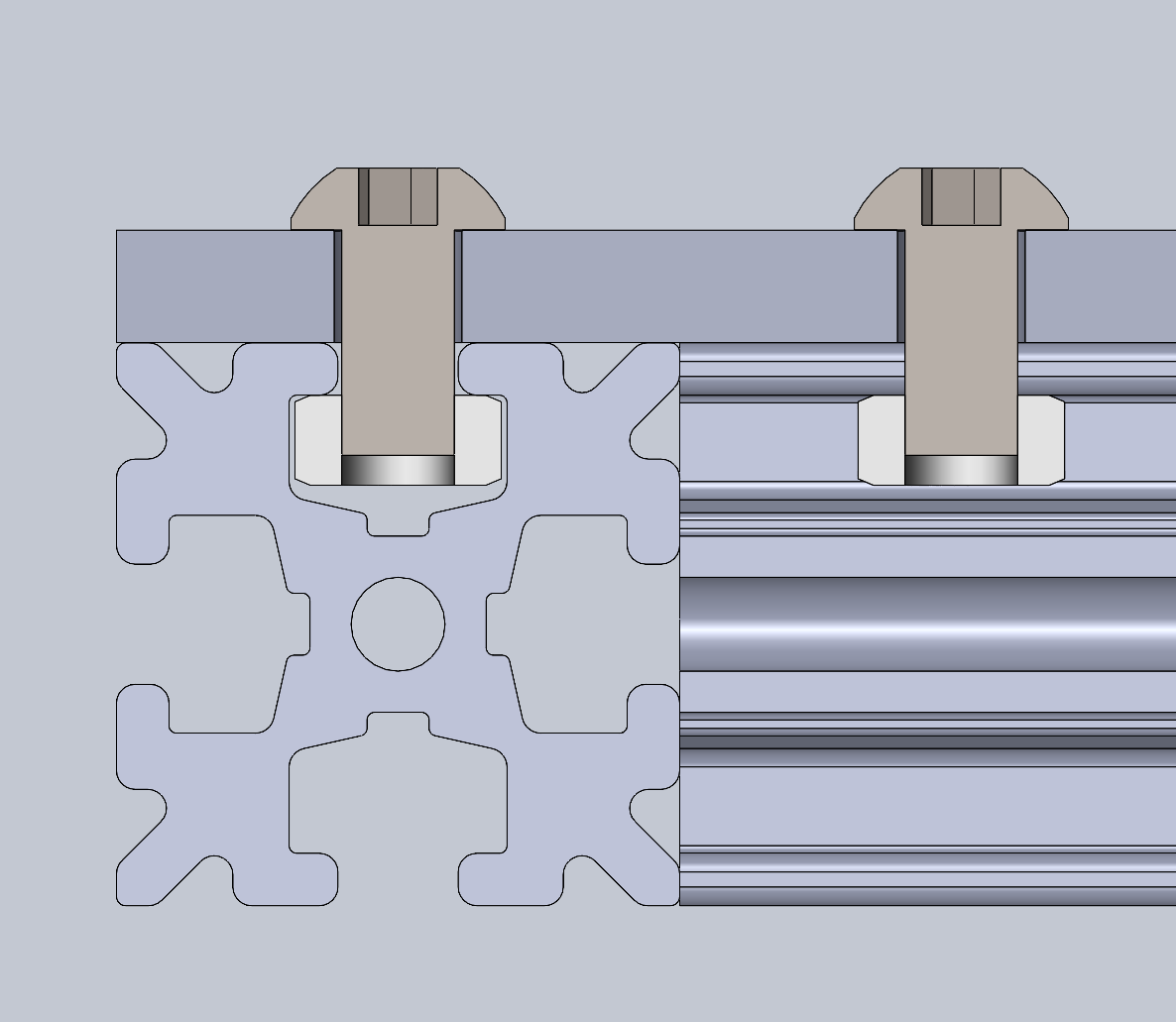

Section view of the slot connection. The M3 screw length is chosen to engage the nut without touching the extrusion.¶

Extrusion Joining Plates¶

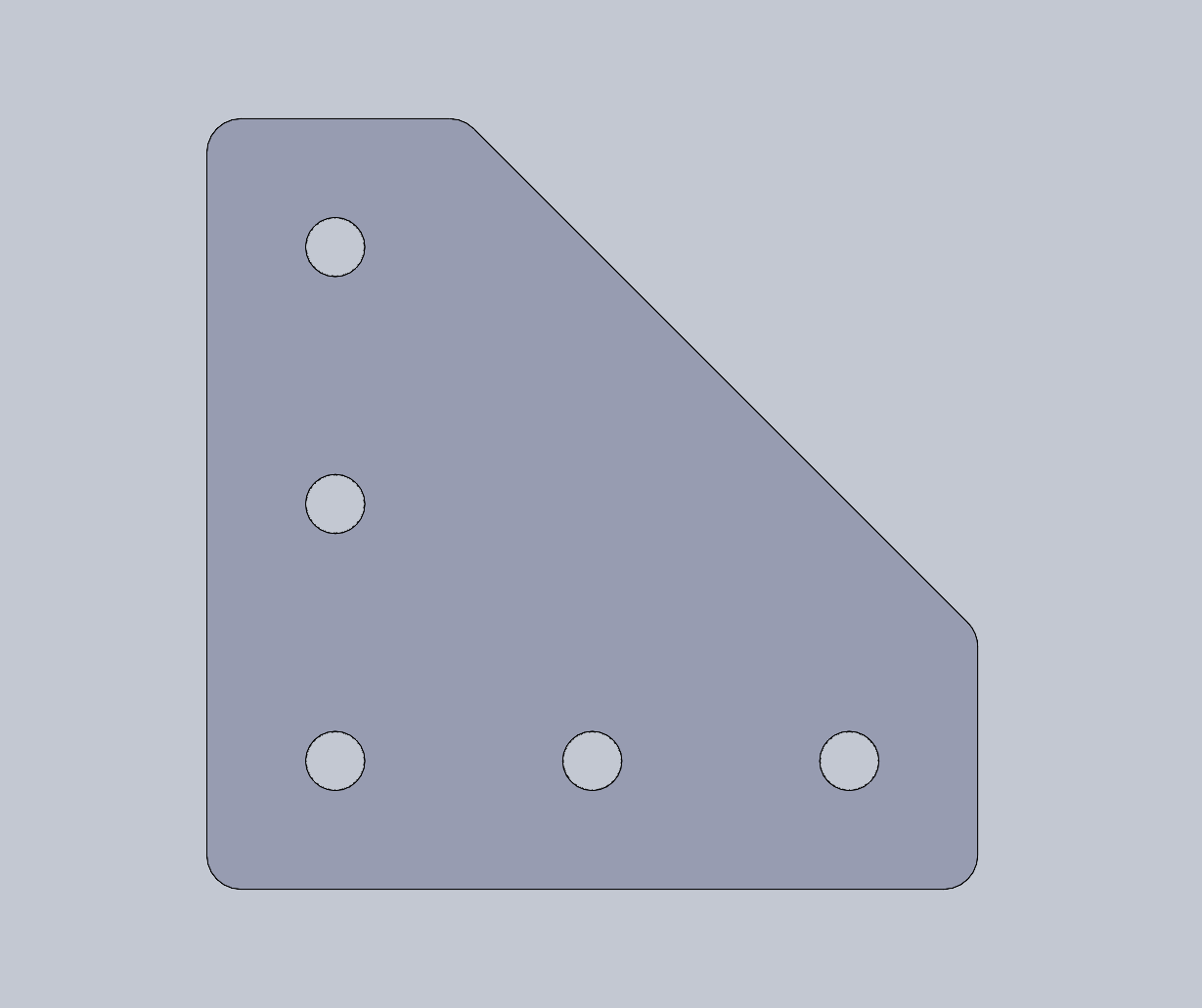

Corner bracket, typically used for right angles at corners.¶

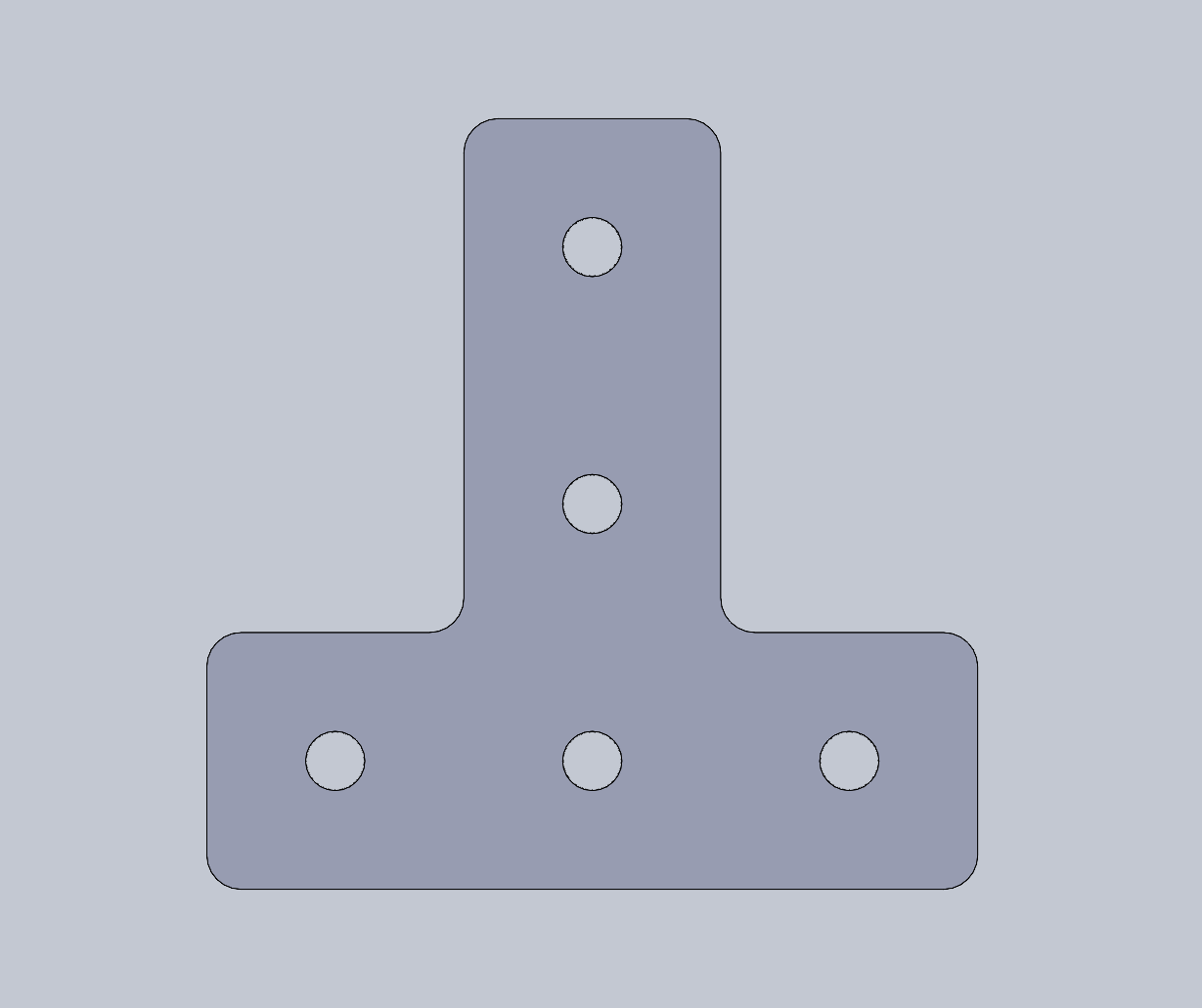

T bracket, typically used for a right angle join in the middle of a length.¶

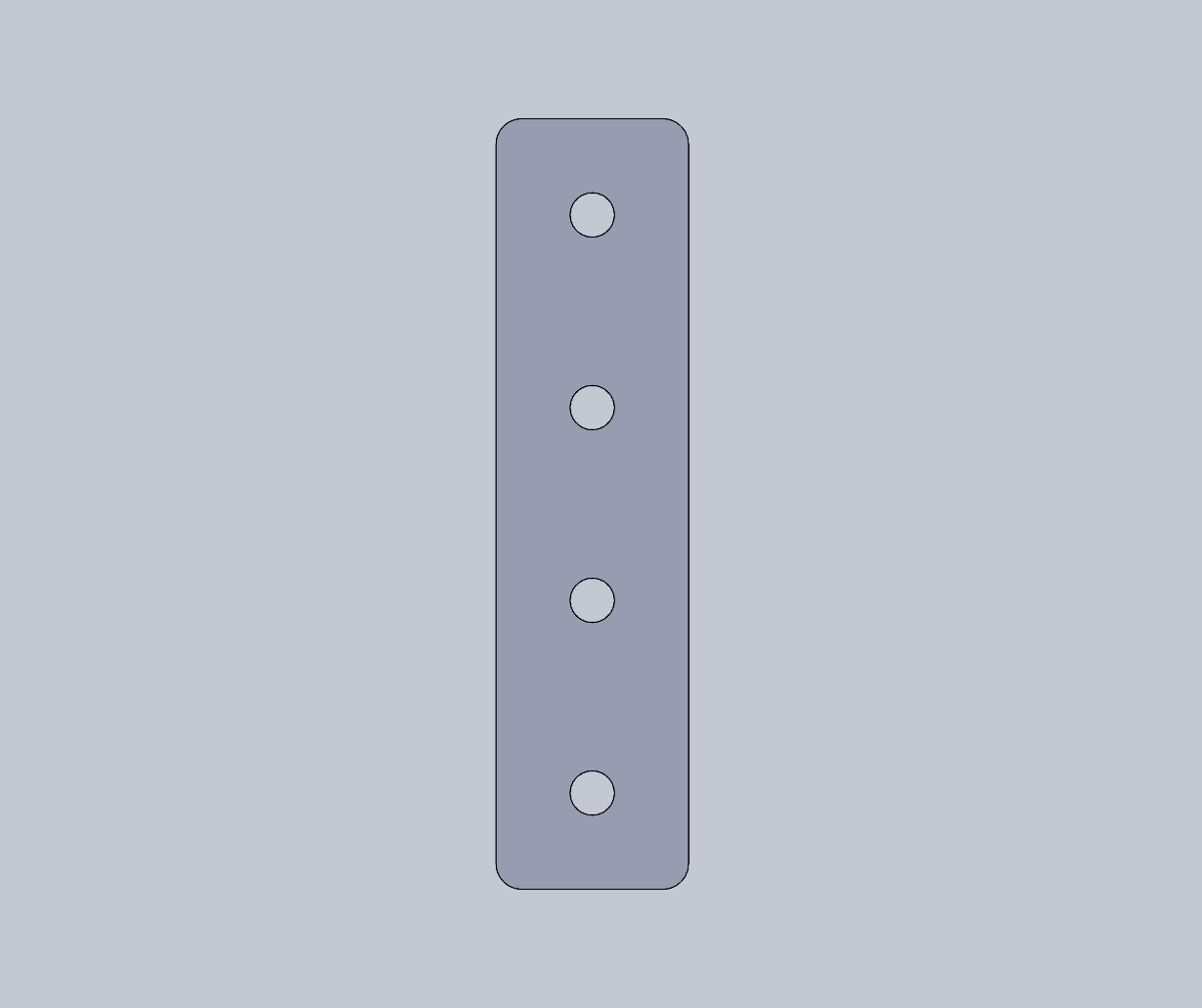

Straight joining plate with four holes. May be used to join two extrusions end to end.¶

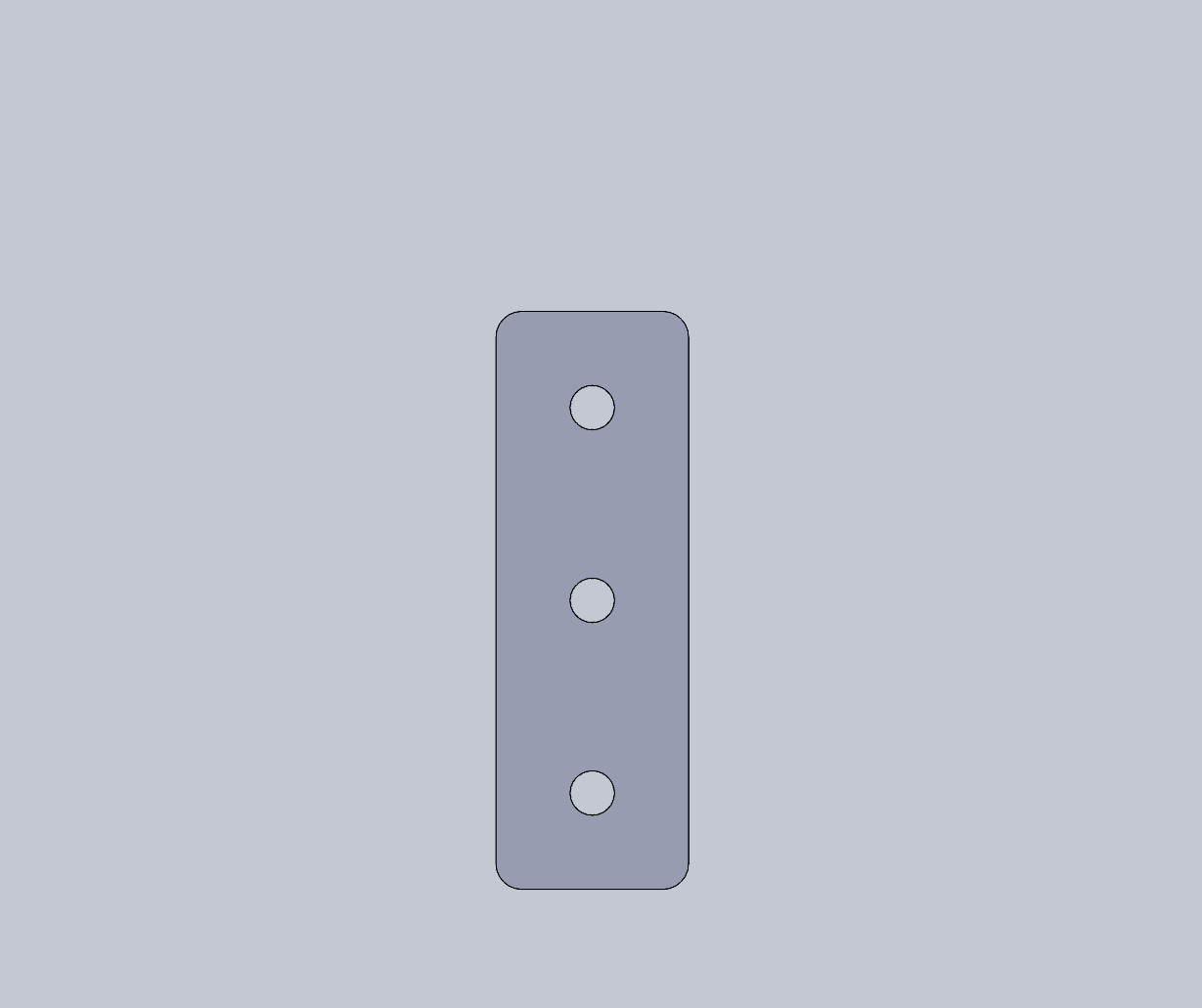

Straight joining plate with three holes. Several other sizes are also

available as configurations in the straight-bracket.SLDPRT part file.¶

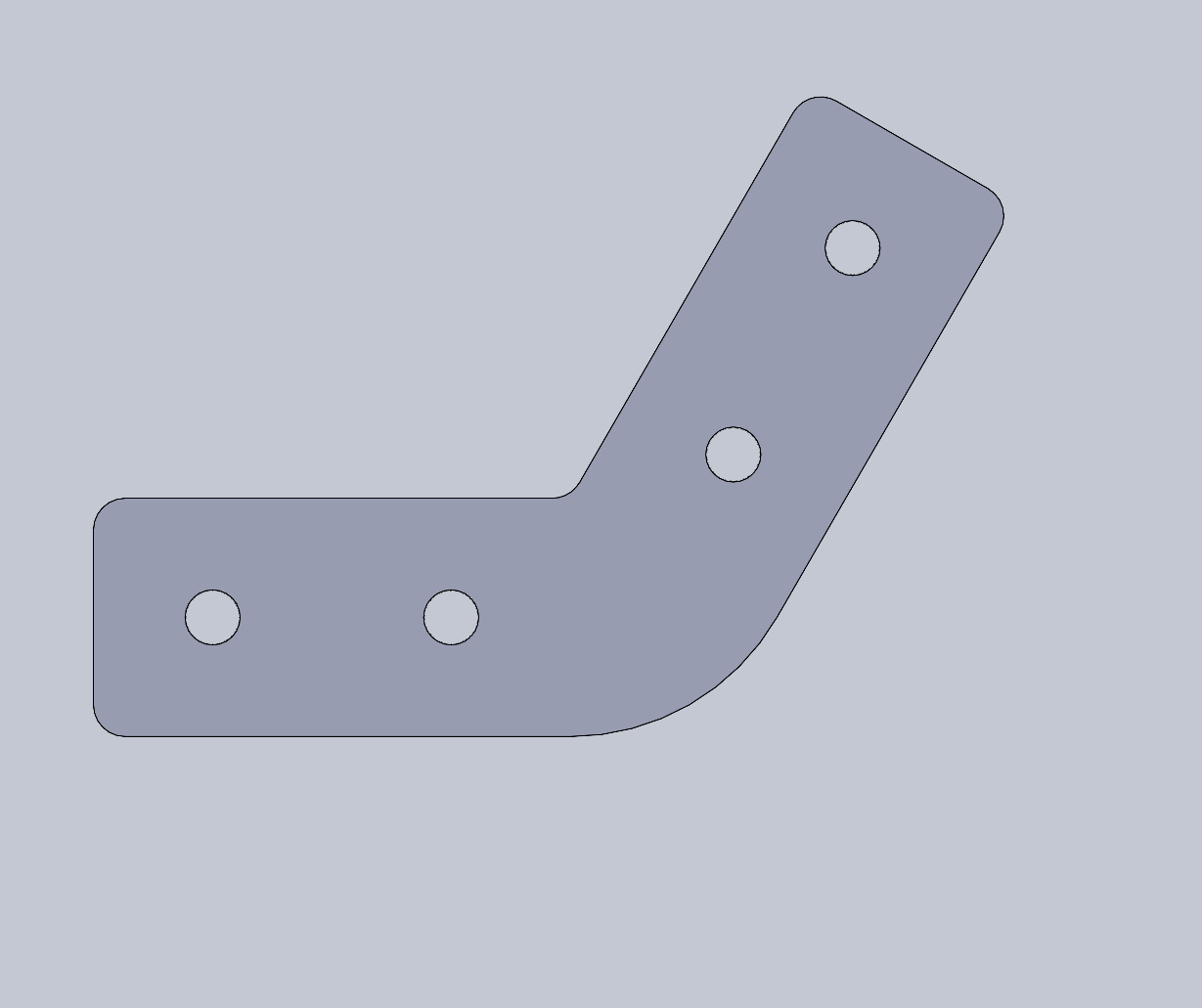

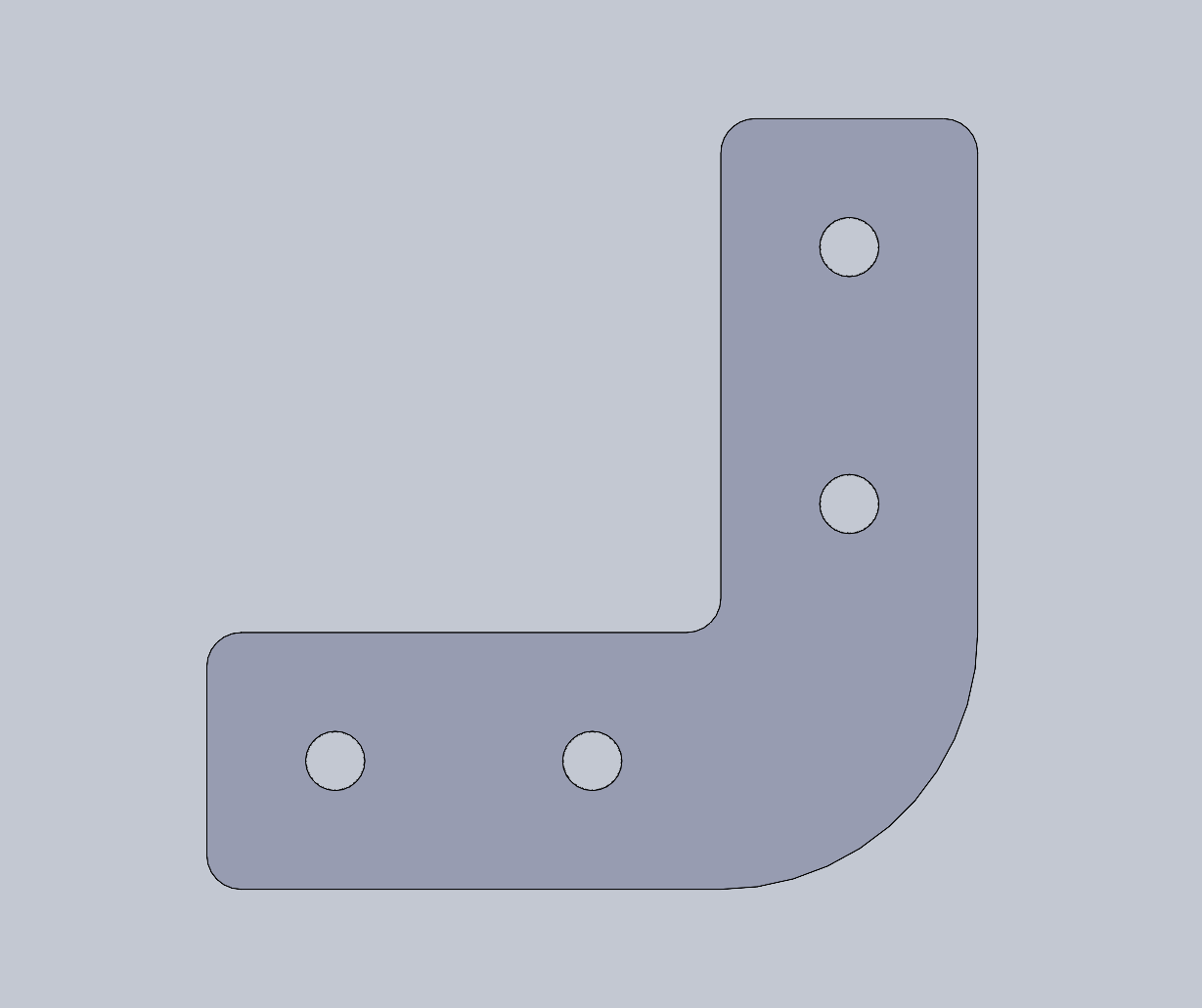

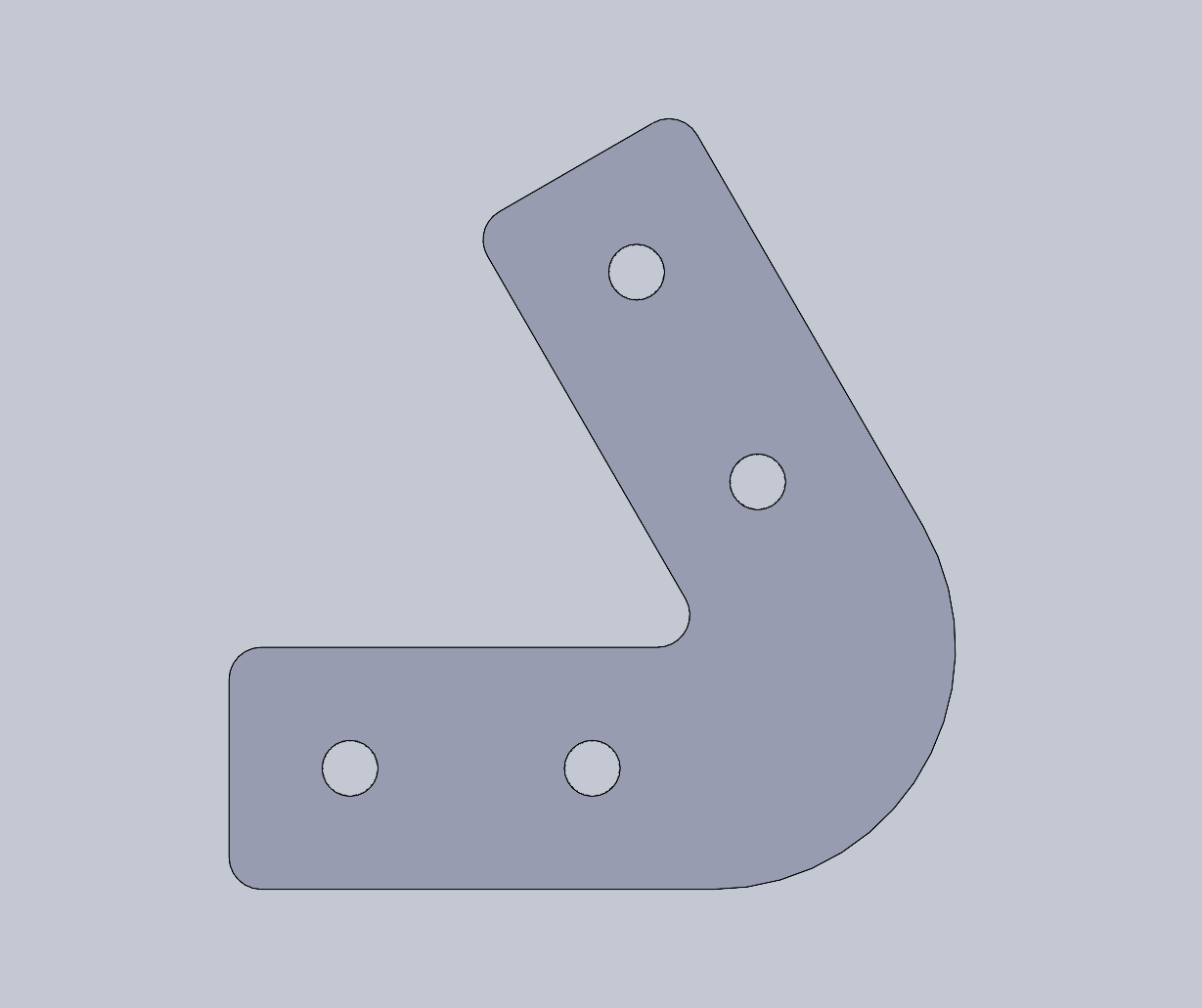

Angle Joining Plates¶

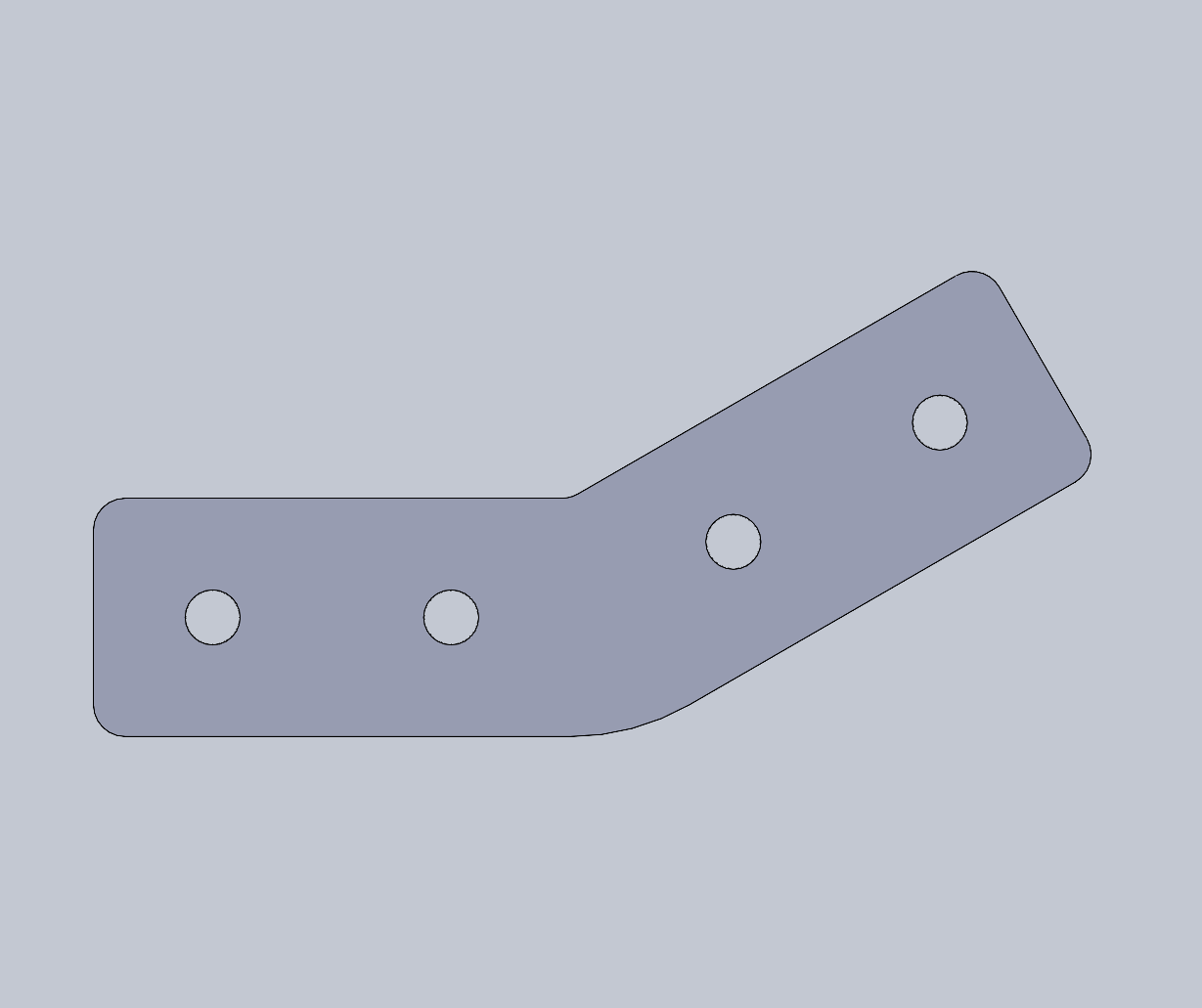

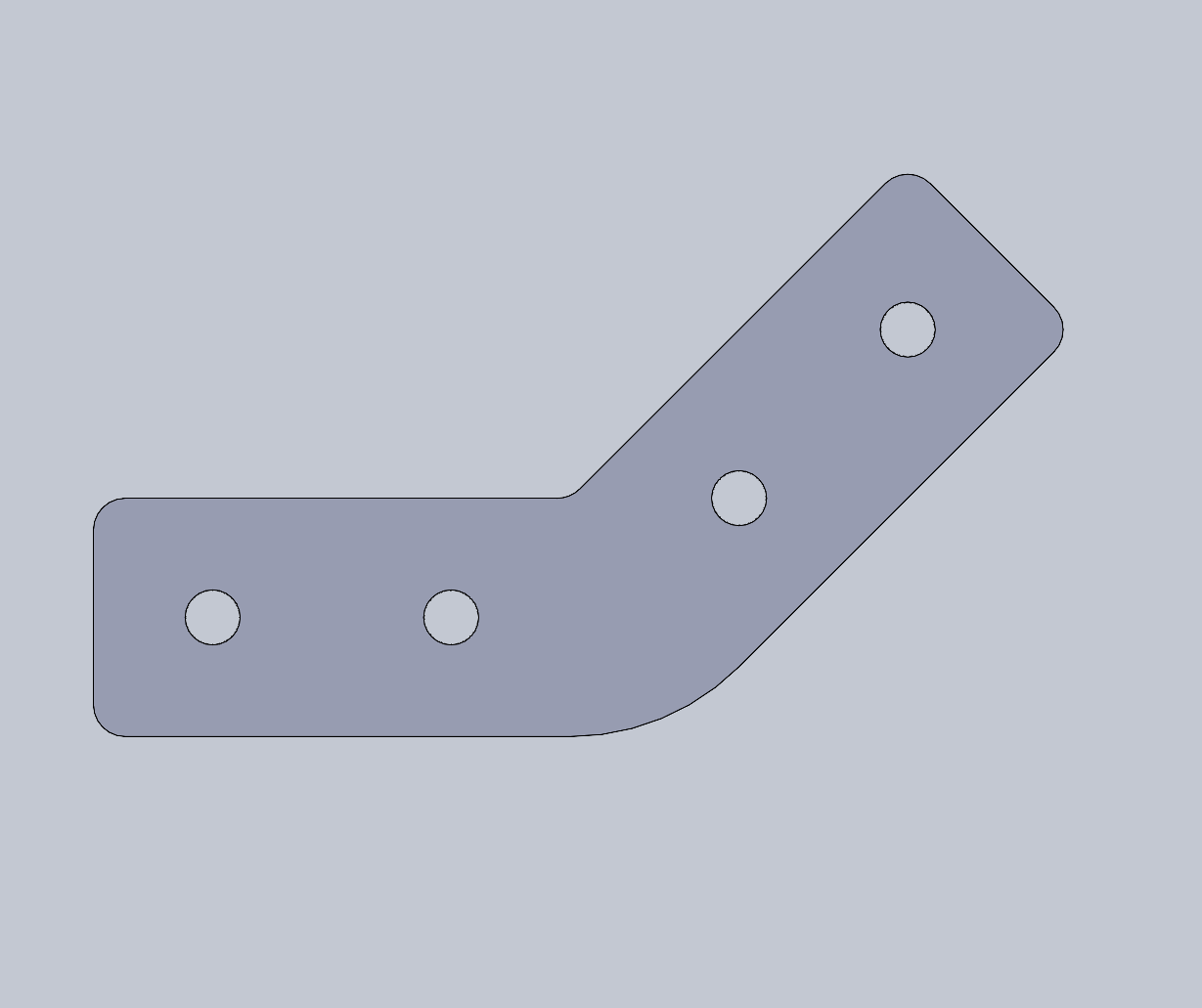

The following renderings are all different configurations of the same angle-bracket.SLDPRT file.

Angle bracket for 30 degrees.¶

Angle bracket for 45 degrees.¶

Angle bracket for 60 degrees.¶

Angle bracket for 90 degrees.¶

Angle bracket for 120 degrees.¶