For this prototype, we addressed a few issues that’d come up earlier. For the fabric attachment, I crafted a device using a chopstick and thread that allow for even dispersal of dye. We extended the range of motion of the motor, using a straw as an attachment. Even without a counterweight, our motor and string seems to be moving seamlessly. Our fabric now penetrates straight into the water because of the pointed tip, rather than fighting surface tension and floating around the surface of the water. We decided to finalize the dyeing techniques this weekend or in class tomorrow — so we are going to try out shibori dyeing techniques (specifically, accordion folds with rubber bands), though we recognize that we might not retain a triangular shape. If that’s the case, we’ll add a paper clip or a weight to the bottom of our fabric to break surface tension. I also attempted a makeshift resist using oil pastel, an added layer to this project through a reveal element through the lack of dye in certain areas.

We are still struggling with the code and the motion, but our device is intended to submerge a piece of fabric into dye over the course of the day. We were able to restructure the tasks into sub tasks. This alleviated the sub problems of the overall function and ensured that if any sound interruption were made then the path of the motor would continue. I added in some helper function to take care of sound and to calculate the direction in which the motor should actually be moving.

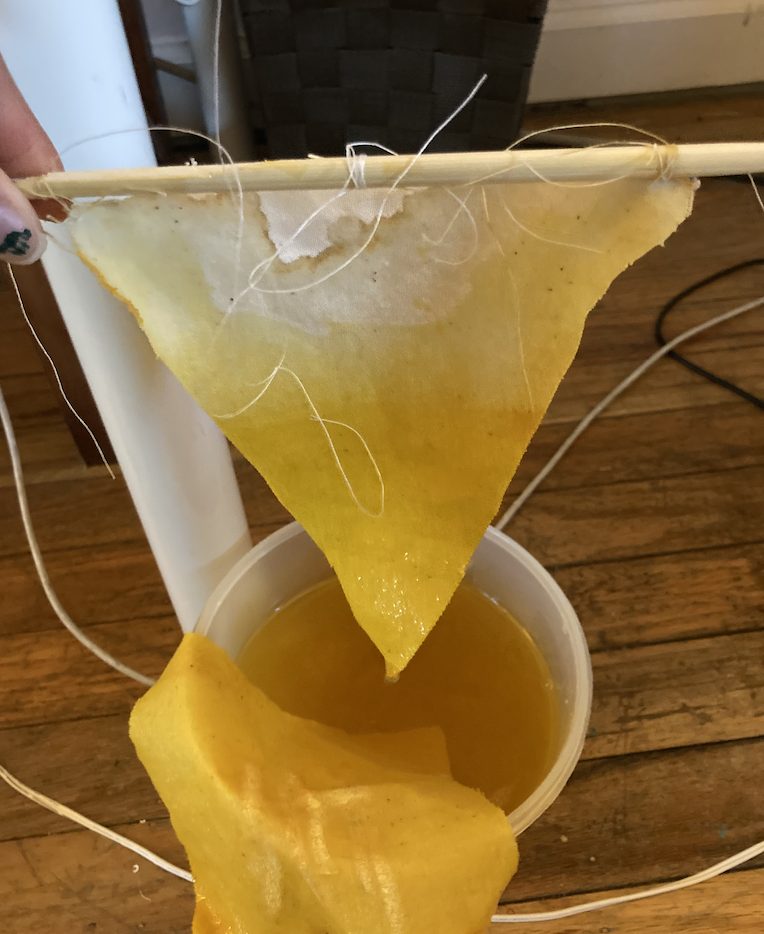

In this iteration, we tried the turmeric again (this time adding more powder) to keep its sunny color consistent with one of our active states (when it is bright out). Here is the pigment after leaving the fabric submerged overnight:

Leave a Reply

You must be logged in to post a comment.