Cam-Action Tubing Clamp¶

This example is a demonstration of using a cam to act as a clamp. It also provides a functional design for an adapter plate to lock onto round tubing. The available sizes have been chosen to be compatible with the various tubing diameters within the C-Stands we use. This may be useful as a light anchor, gobo mount, motor mount, etc. within the studio.

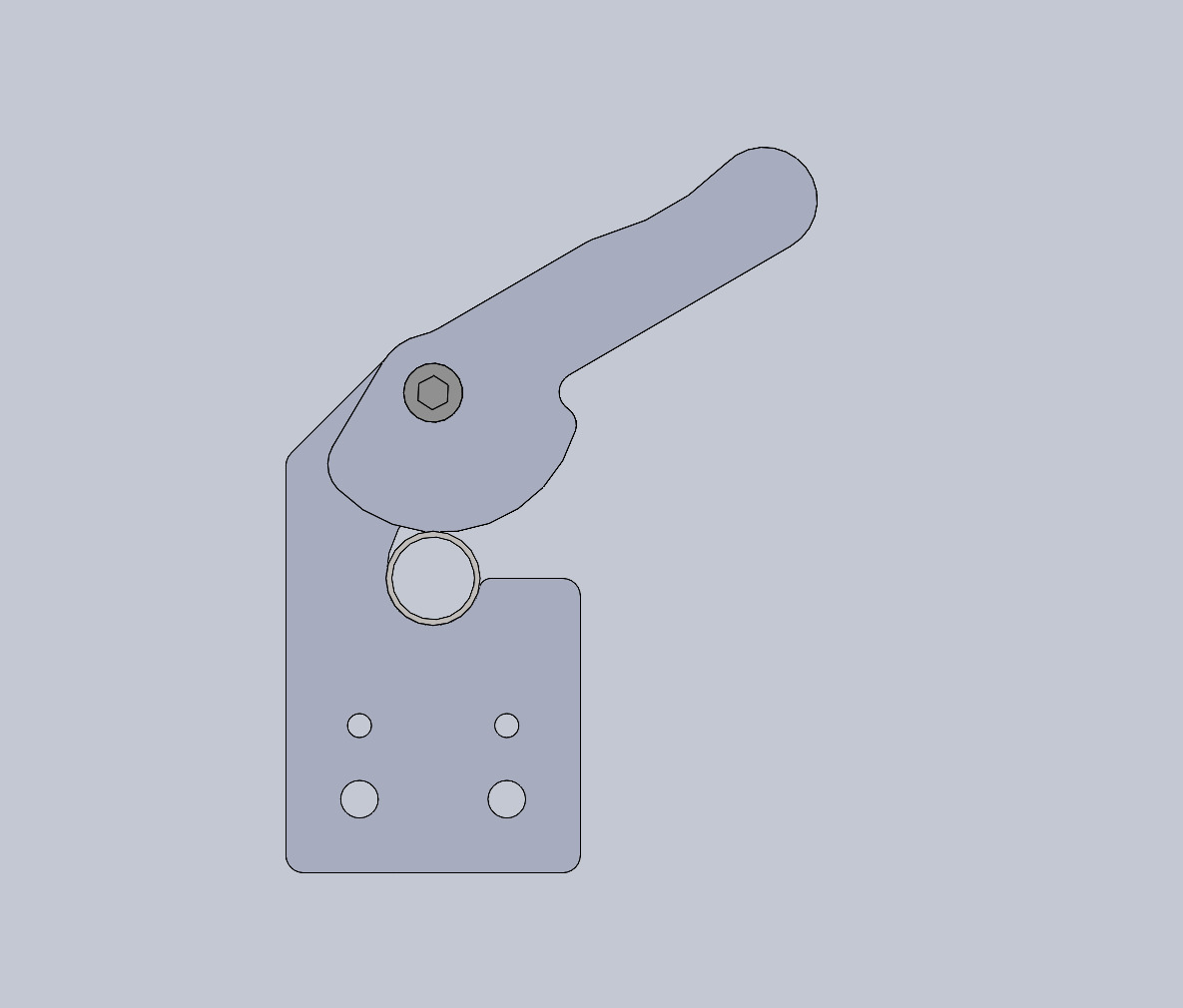

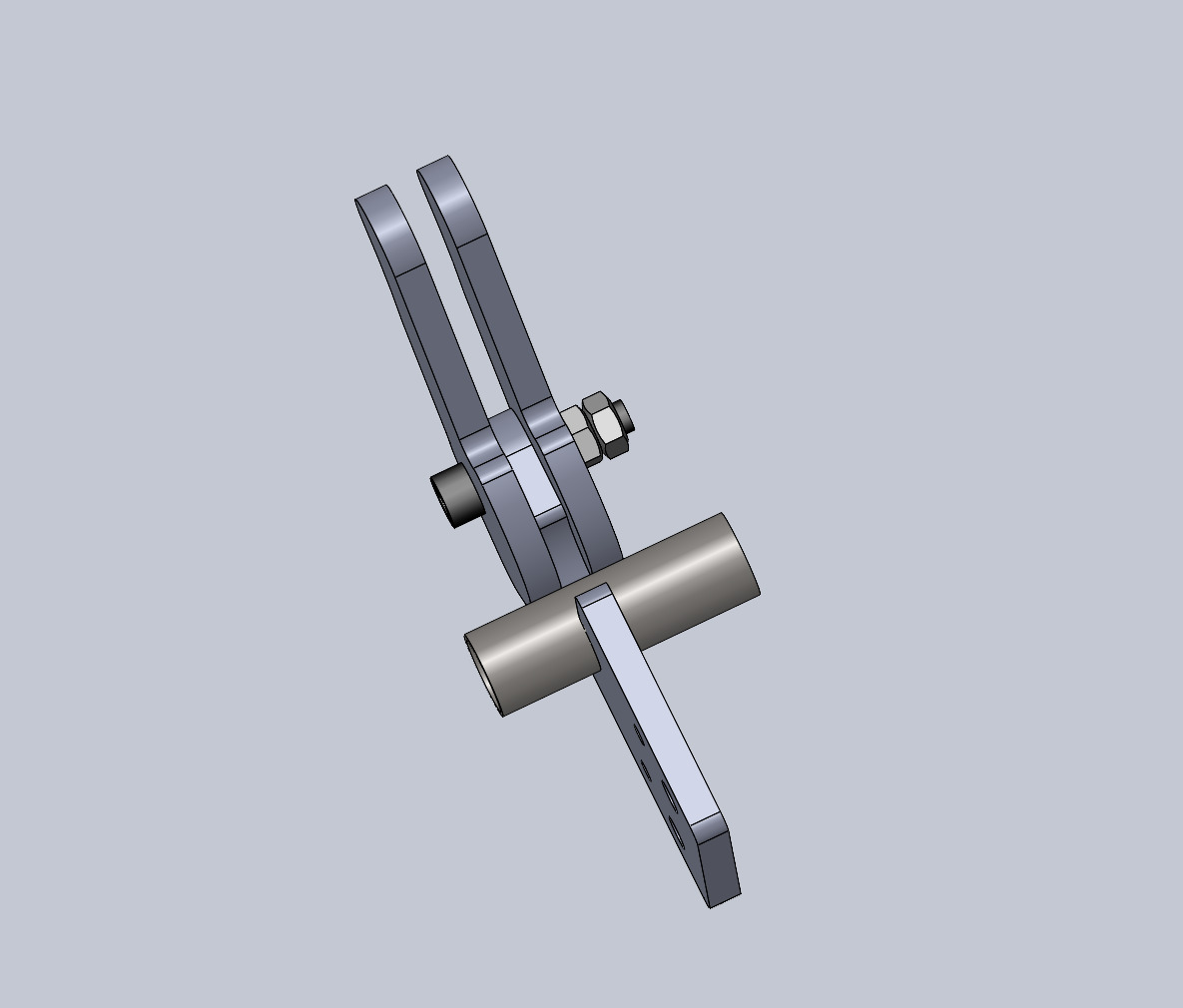

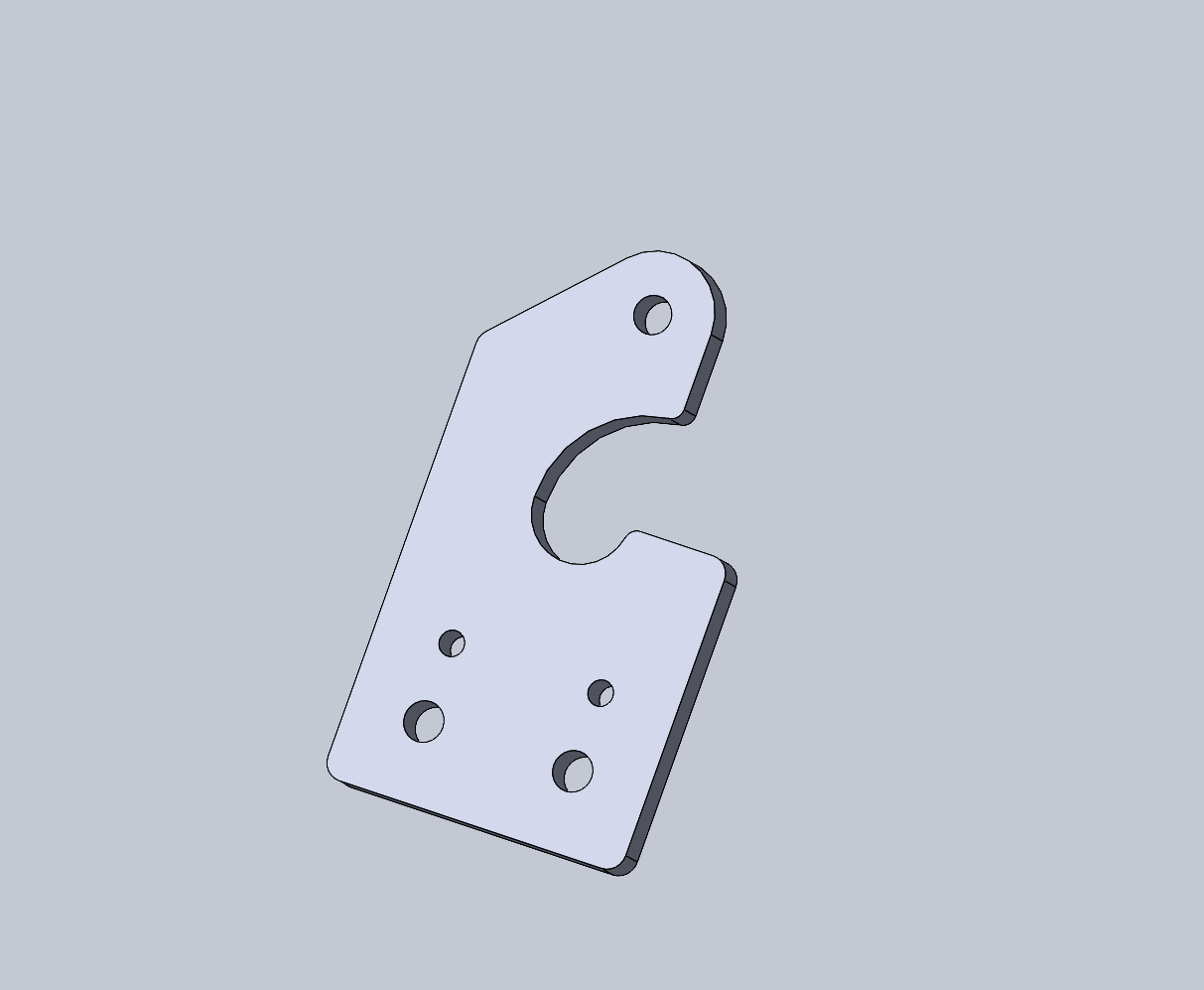

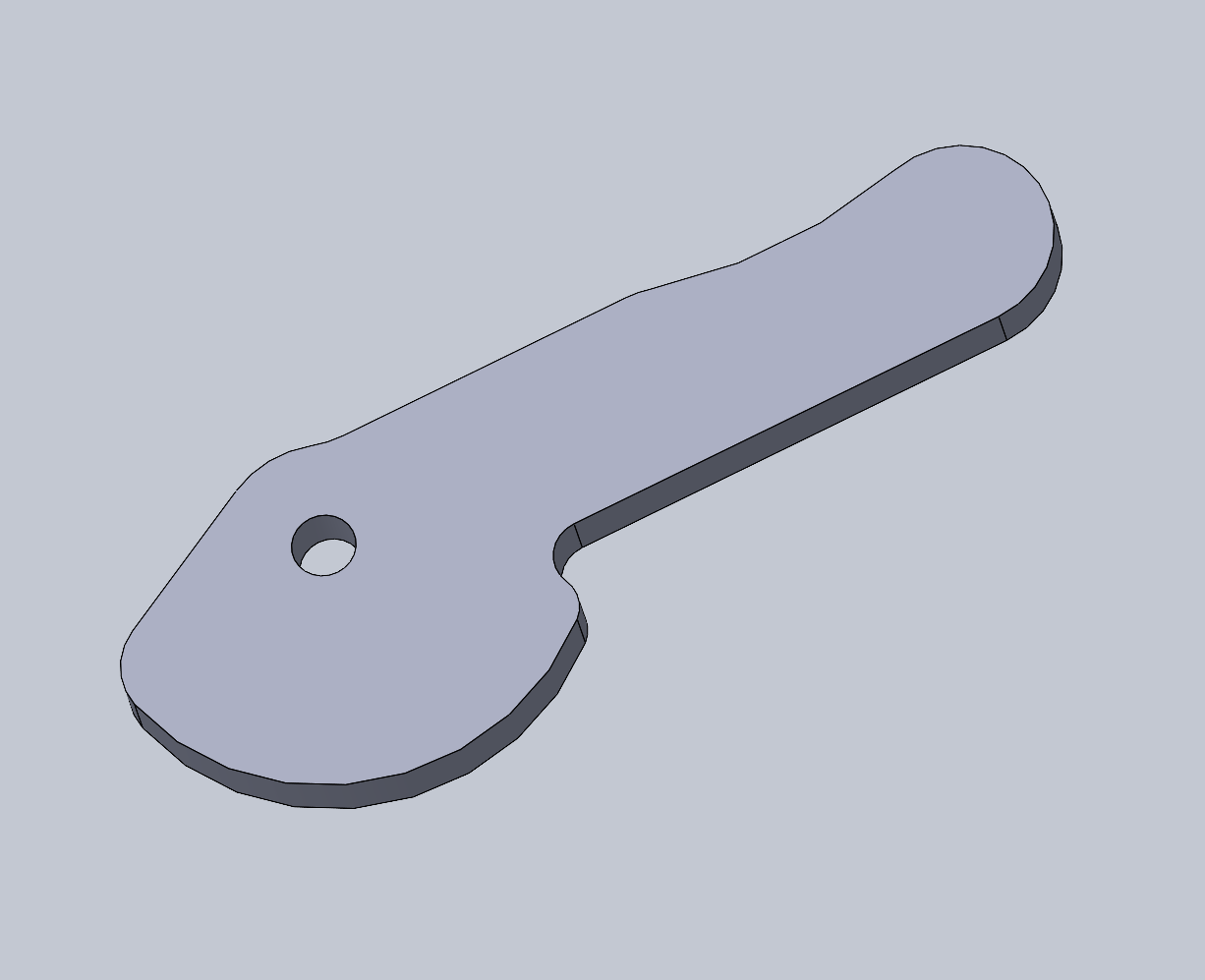

The cam is duplicated on both sides of the grid plate to provide symmetric forces. The curved cam surface is shaped to provide a steadily increasing radius as the handles are compressed. This squeezes the tube into the circular cavity of the grid plate. The shallow cam slope keeps the tubing friction forces within the limits of the contact friction for a passive frictional lock. The other end of the cam is designed to allow the tube to fit through the full opening so the device can be slipped around a tube at any point without inserting from the end. A screw is used as a shaft for the handle, with two nuts tightened against each other to leave handles loose.

One the left is the basic grid plate with a round cavity sized for a particular tube diameter. On the right is the common cam lever part with cam surface and handle, two needed per clamp.

The SolidWorks model files and individual DXF cutting files may be found in the tubing-clamp folder or may be downloaded as a single file as tubing-clamp.zip.

C Stand Details¶

We have two different kinds of C-stands in the Media Lab, each with different tubing diameters.

Impact LS-CT40MBK Turtle Base C-Stand

Matthews Studio Equipment BY56040

Tubing Diameters

tube |

Impact |

Matthews |

|---|---|---|

leg |

25 mm |

25 mm |

base (vertical) |

35 mm |

32 mm |

base slider 1 |

30 mm |

25.5 mm |

base slider 2 |

25 mm |

19.5 mm |

end arm |

16 mm |

16 mm |

Tubing Clamp DXF Profiles¶

common cam handle: tubing-clamp-cam.DXF

for typical 16 mm end tube: tubing-clamp-plate-16.DXF

for larger 35 mm base tube: tubing-clamp-plate-35.DXF

for medium 25 mm base tube: tubing-clamp-plate-25.DXF