Design Example: Laser-Cut Open Mold for Flexure Part¶

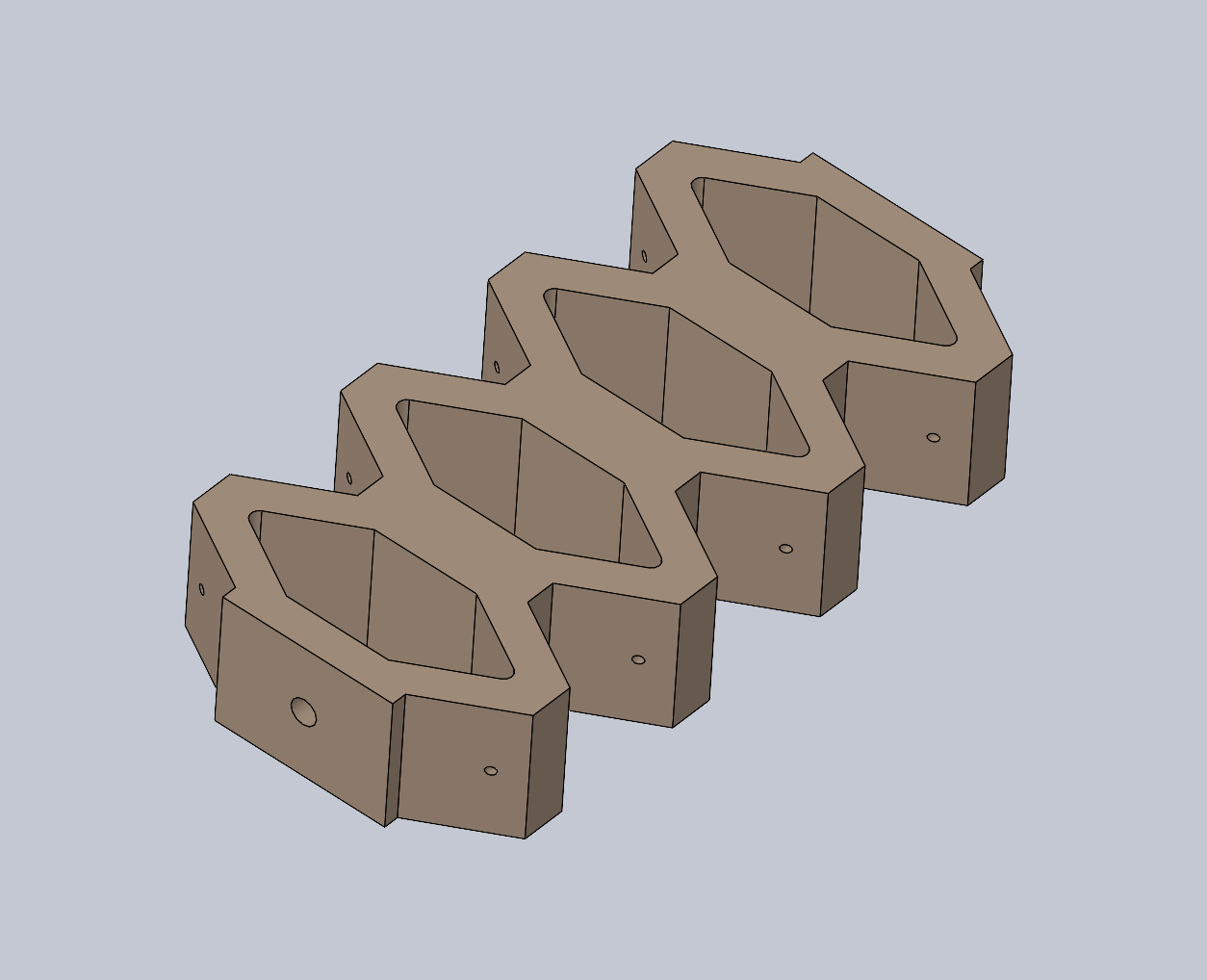

Rendering of flexure part to be cast using silicone in a mold constructed from laser-cut acrylic laminations. The part is approximately 60 mm square, is 9 mm thick, and has 18.8 cc volume.¶

This sample demonstrates the design of a basic silicone flexure part fabricated using an open mold fabricated from laminations of laser-cut 3 mm acrylic.

The SolidWorks model files and laser-cutting profiles may be found in the SolidWorks/flexure-test-3 folder, or may be downloaded as a single file as flexure-test-3.zip.

SolidWorks Design Workflow¶

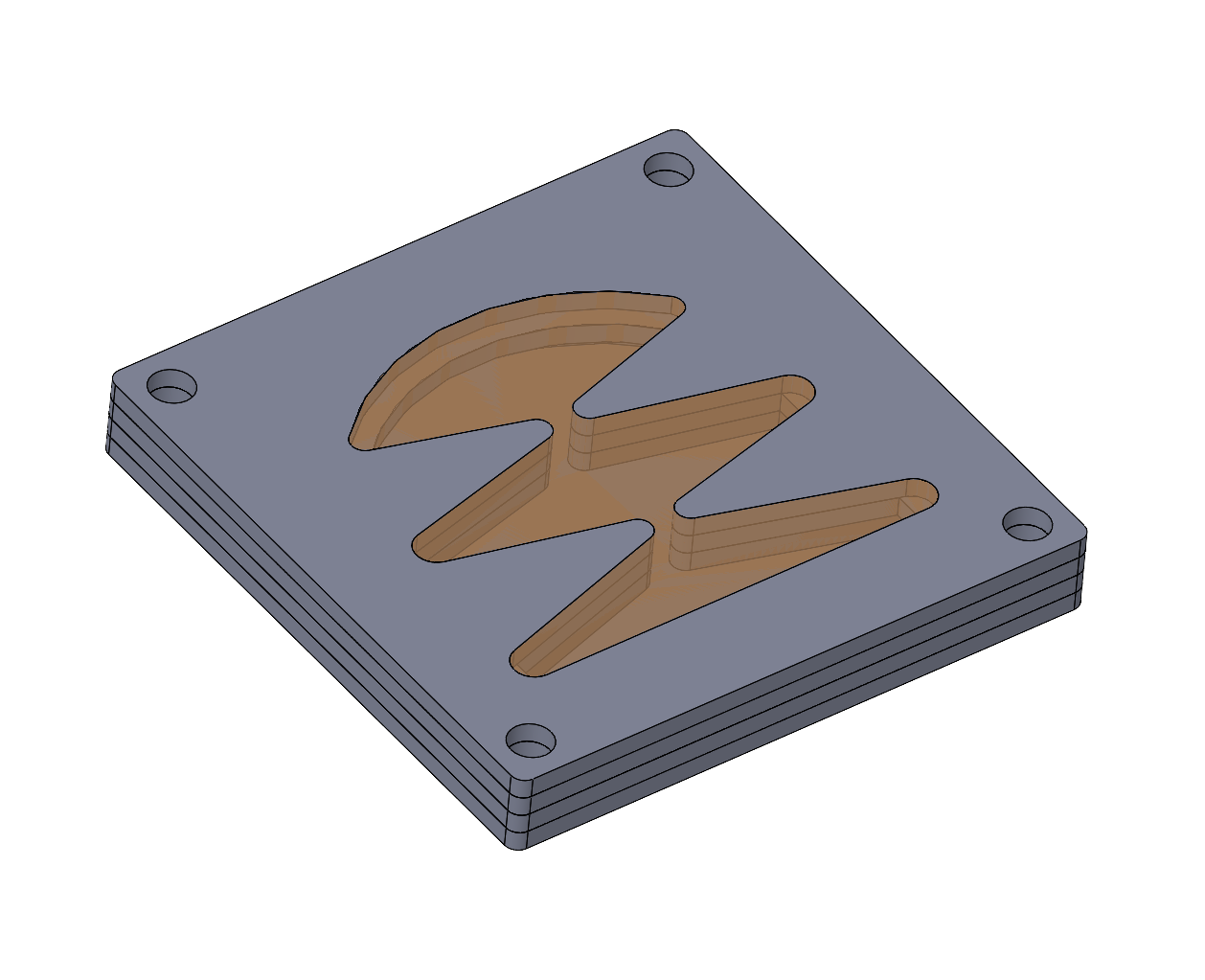

The part was modeled as a solid part with the 3 mm mold lamination thickness in mind. The outer faces are flat as they will be formed by the open top and flat bottom of the mold.

For the single-cavity mold:

The mold blank was modeled as a block larger than the part to fabricate.

As assembly was created using the mold blank.

The silicone part was added to the assembly with mates to align inside the mold part.

The mold part was edited in the assembly context and Cavity feature added to subtract the parts.

The mold part was split into separate 3 mm slices for fabrication.

The slices were each exported as a DXF for laser cutting.

The individual DXF files were arrayed into a cutting layout using Inkscape.

Please note that the design is associative: changes to part geometry will propagate to the mold cavities when the mold assembly files are reloaded and rebuilt New mold DXF files would still still need to be individually exported.

Other Views¶

Rendering of mold showing cavity and slices. The flexure is shown partly transparent.¶