What is it?

Stereolithography takes CAD drawings and turns them into solid, plastic, 3-d objects using lasers.

How does it Work?

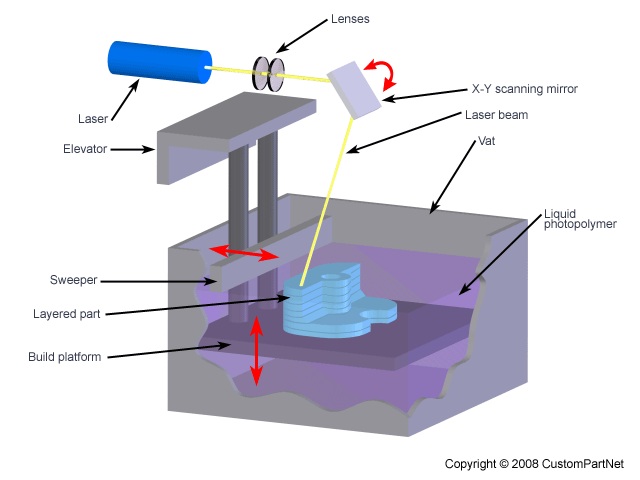

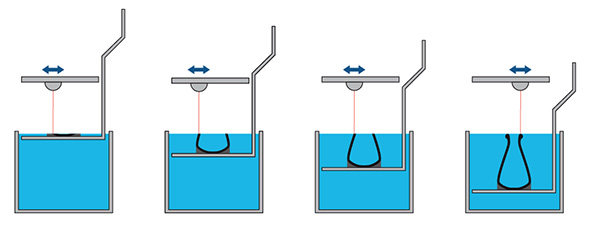

The stereolithography machine contains a reservoir of resin. The laser heats up one layer of this liquid photo-reactive resin over a specific area to harden it. Each layer is a few thousandth of an inch thick. It continues to do this until the object is built up in layers.

As each layer is built, the platform moves down to expose more resin, which allows more layers to be built on top of it.

After the object is completely built up, it is rinsed with a solvent and baked in an oven that cures the plastic.

When should you use it?

The machine itself is very expensive — at around $250,000. It is cheap and fast, and can be used to make accurate prototypes. It is mainly used to make commercial prototypes. Size limitations differ by machine, up to 20x20x20 inches.

What materials does it use?

Liquid photopolymers, sensitive ultraviolet light.

How to get access to it?

University of Pittsburgh Manufacturing Assistance Center (MAC):

http://www.engineering.pitt.edu/Departments/Industrial/_Content/Computing-Facilities/Computing-Facilities/