Injection Molding at Carnegie Mellon

What is injection molding?

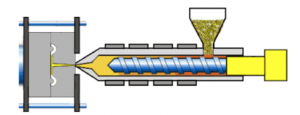

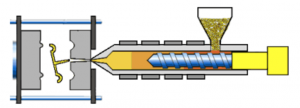

Injection molding is a manufacturing process typically used for mass production and is performed by injecting molten material into a pre made mold. First, a mold of the desired part is created. Then, material granules are melted into liquid molten and injected into the mold. The mold then undergoes a high pressure holding until the material dries. Finally, when the part is ready, the mold can be opened and the part retrieved. This process can be repeated several times since the mold is reusable. Typically, some form of plastic polymer is used as the material for injection molding.

Diagram of injection molding process

When should I use injection molding?

Injection molding is often used to manufacture parts en masse because the price to make each part is extremely low, so the main expense comes from creating the original mold. Injection molding is also good for making parts that are identical to one another. To make just one part, however, injection molding might not be the best method of manufacturing because of how expensive and labor intensive it is to create the mold. You must first design a prototype part (using a CNC machine or something similar), then design a mold tool that shapes the prototype part. Additionally, since the mold tool is usually made out of metal, it is difficult to make changes to a mold after it is completed. Injection molding is also not the best for manufacturing large parts since multiple molds would be required.

Where can I find it on campus?

There is no website for injection molding on campus, but to get access, you can email Matt Cline at mc86@andrew.cmu.edu explaining why you are requesting access to the machine. Matt Cline runs the Rothfus Lab (DH A102 which is inside DH A100), which contains the only injection molding machine on campus . Once you have emailed Matt, he has instructional videos that walk through the process of using the machine, and he is quite willing to provide verbal walk-throughs of the machine.

The video animation below provides a rough idea of how the injection molding machine works.

Created by Ben, Nathan, and Sarah.