Design Example: Slider and Rail Systems¶

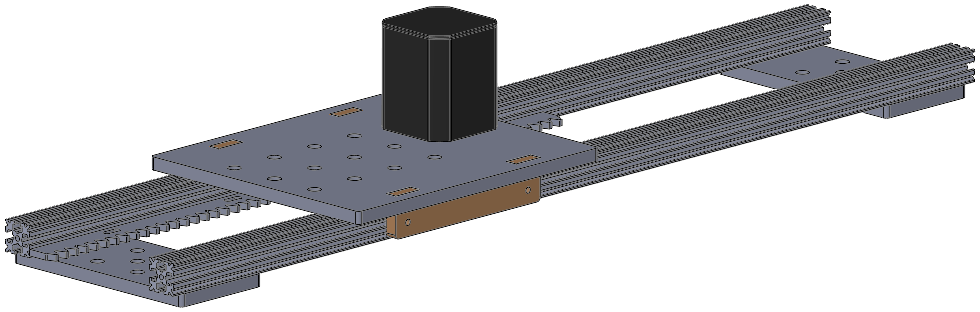

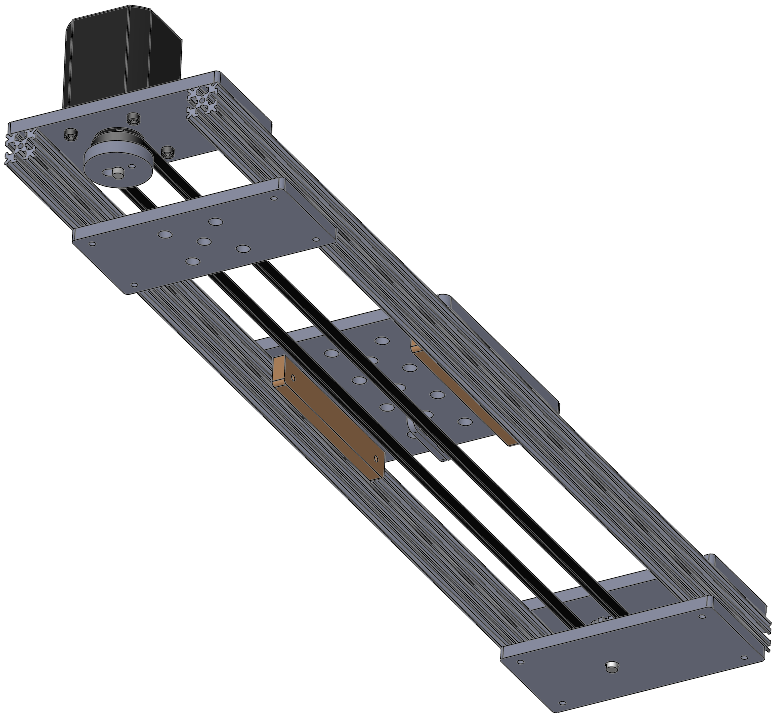

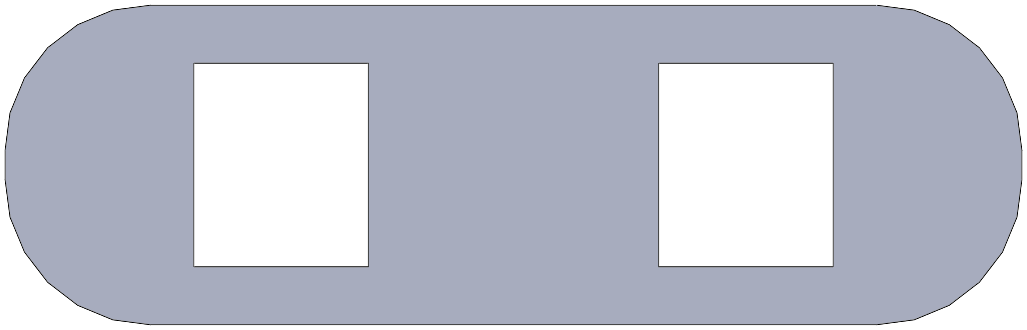

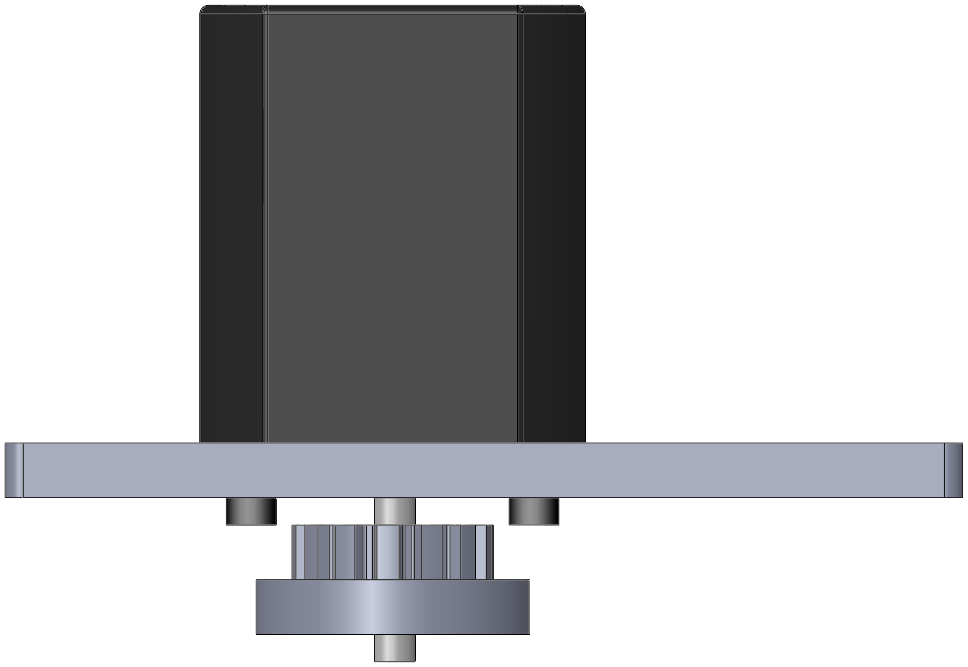

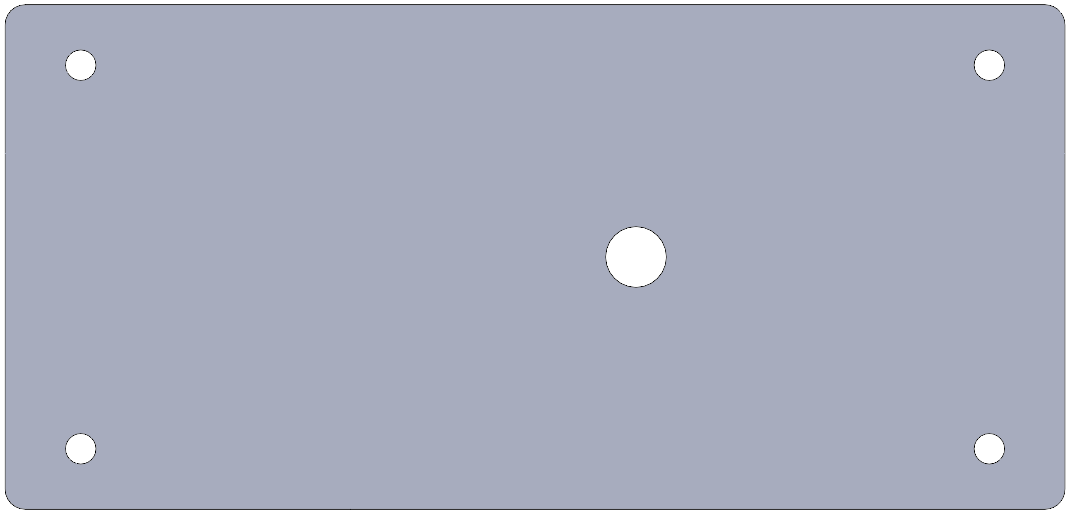

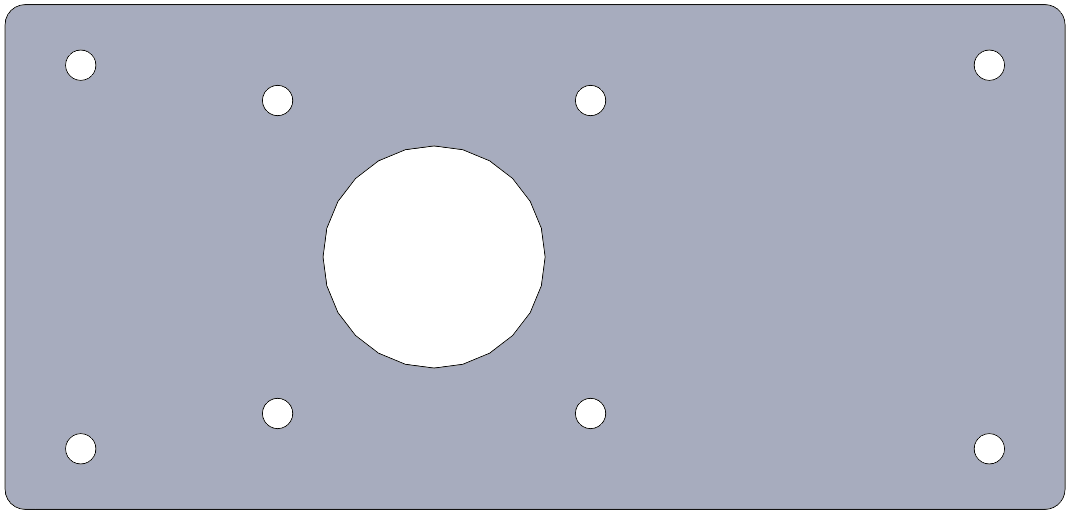

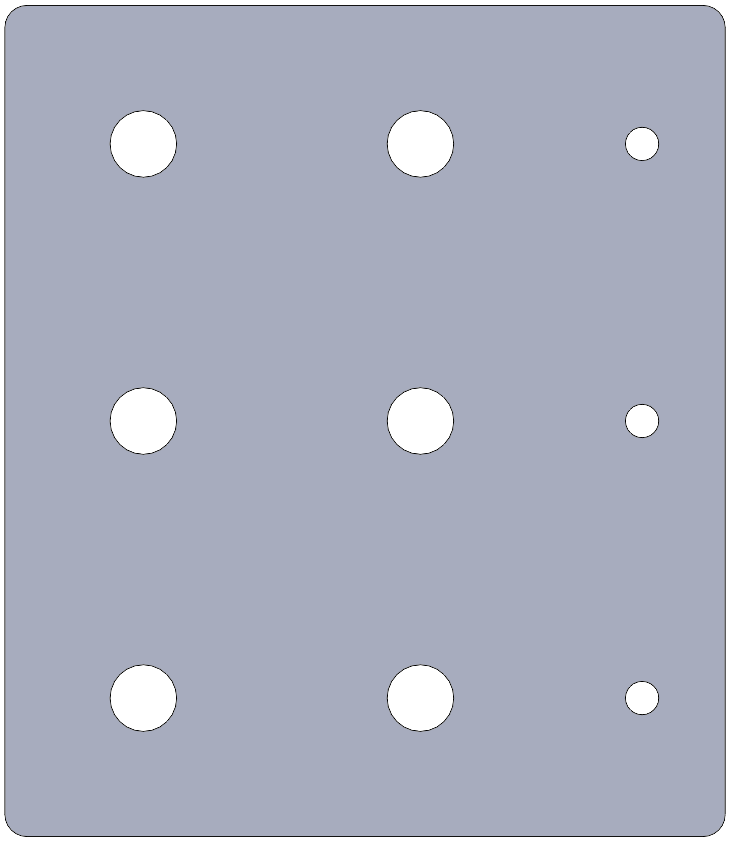

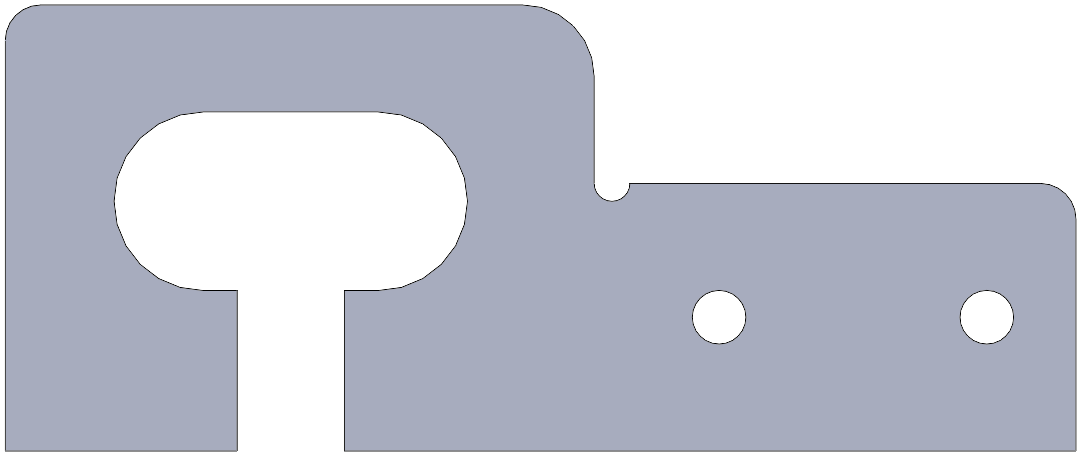

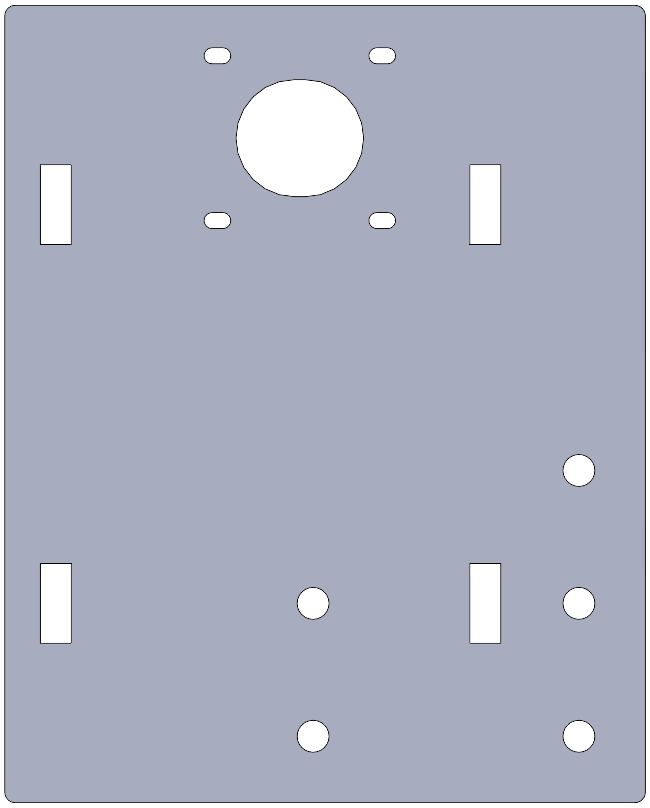

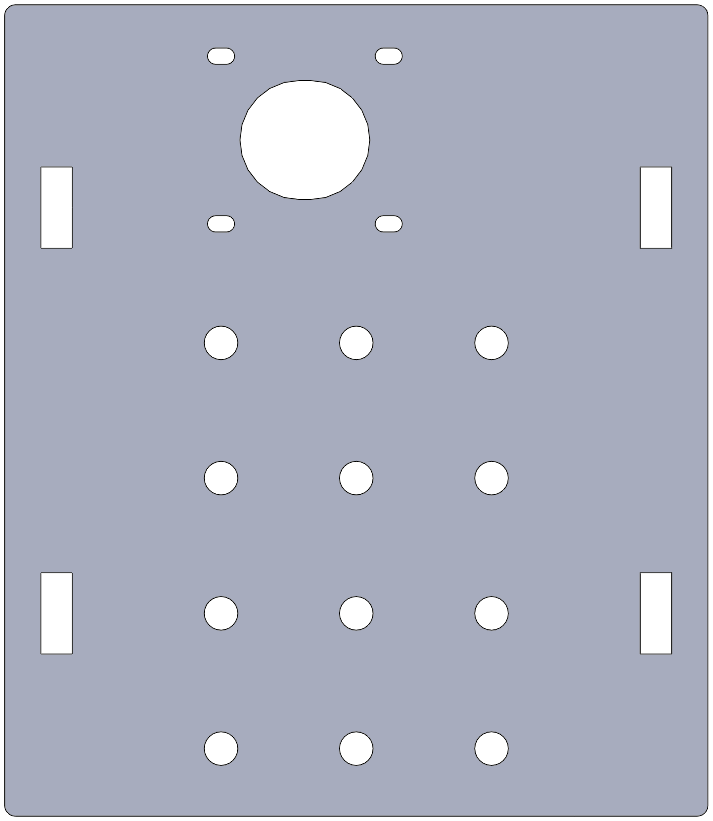

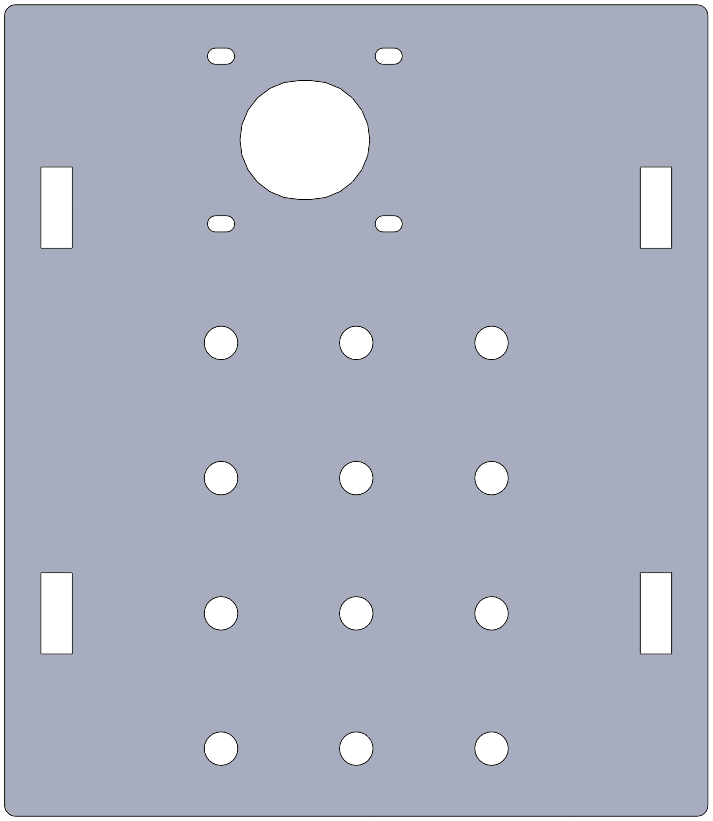

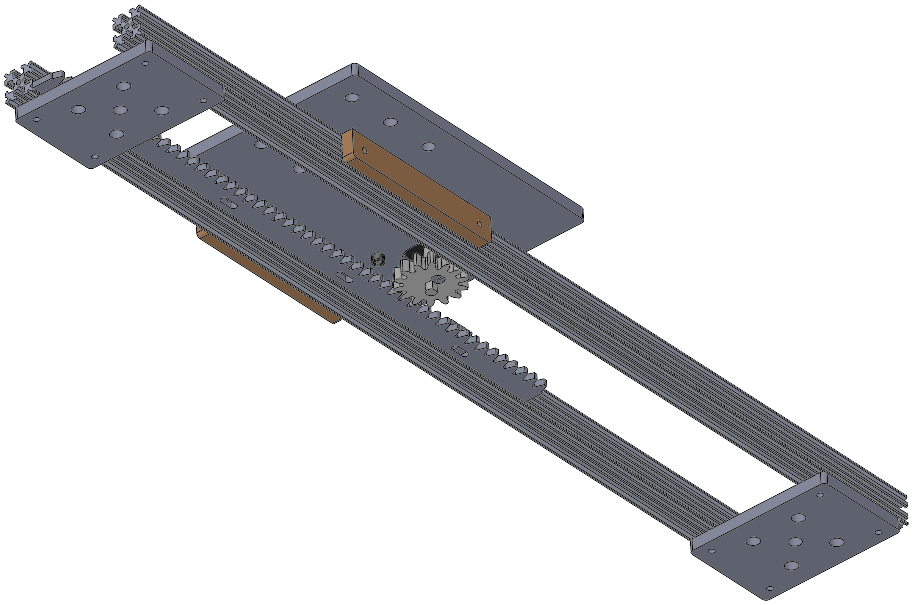

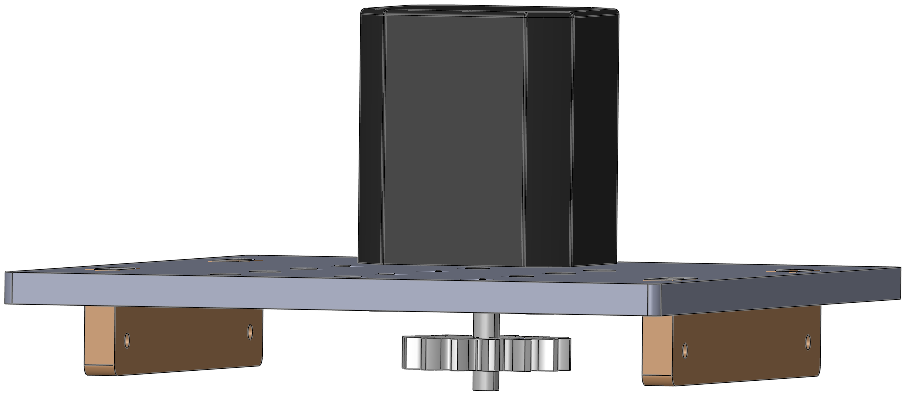

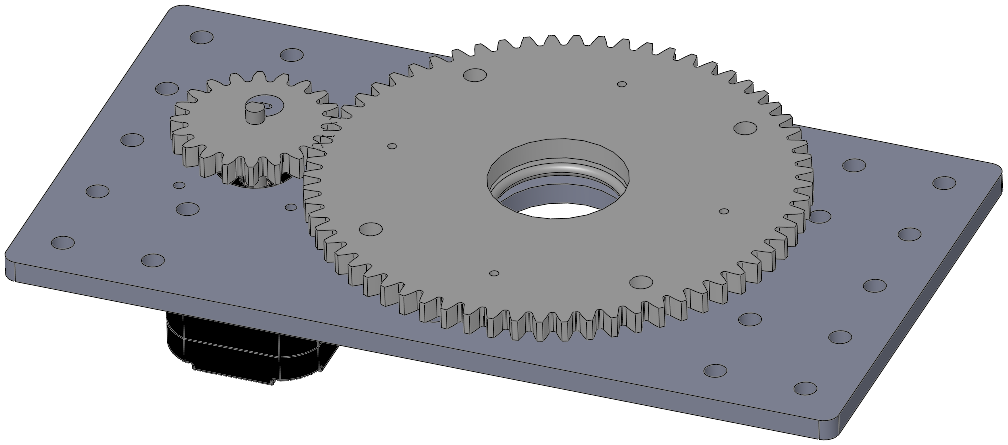

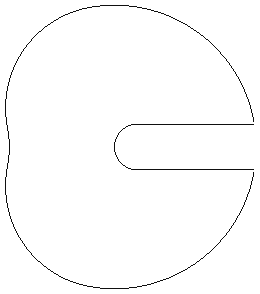

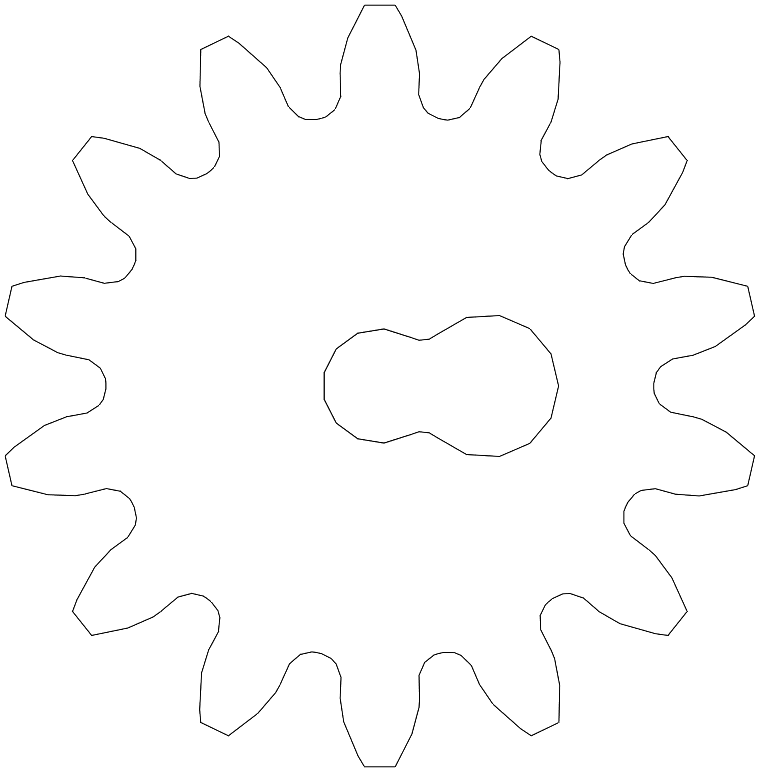

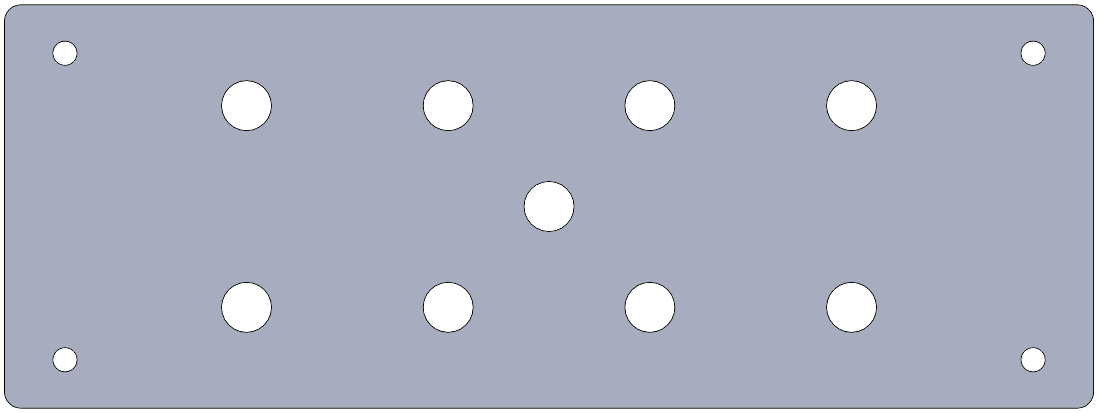

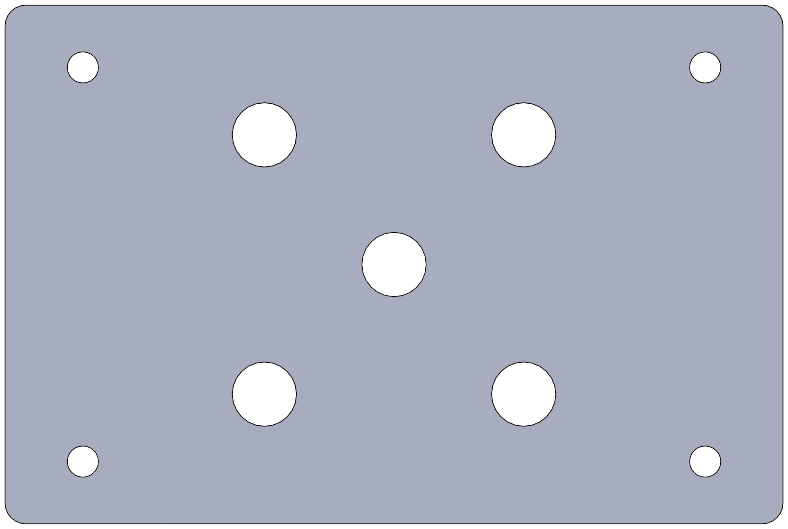

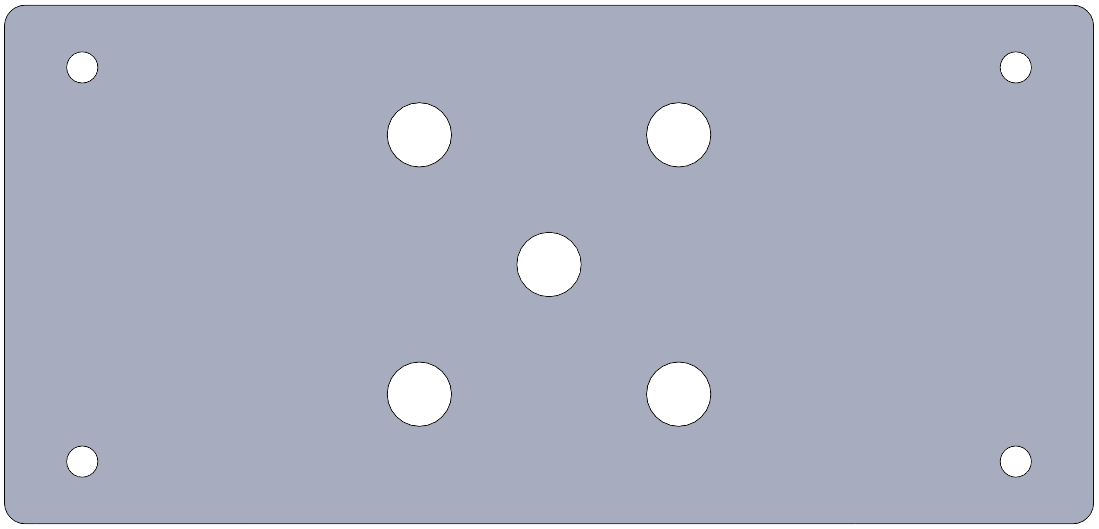

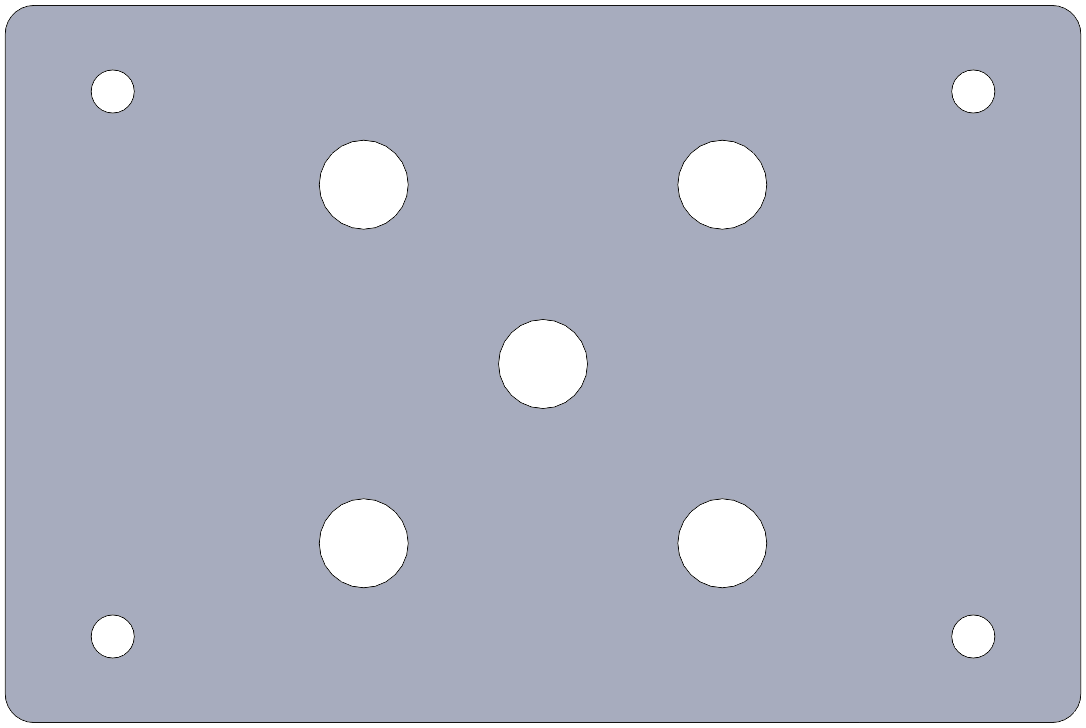

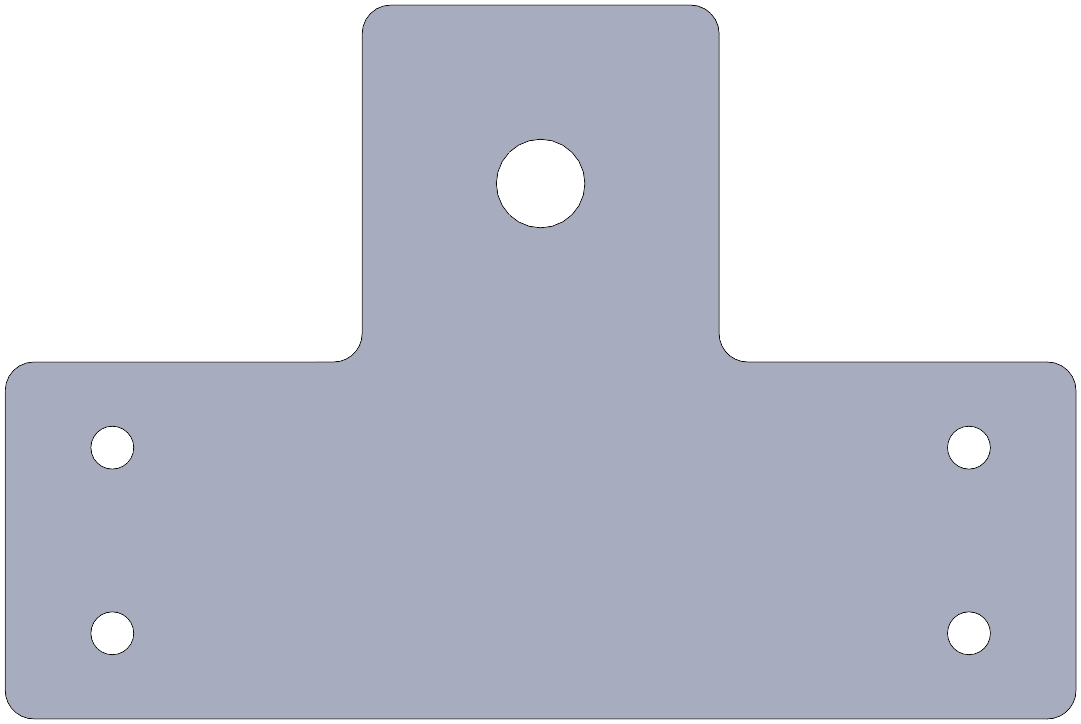

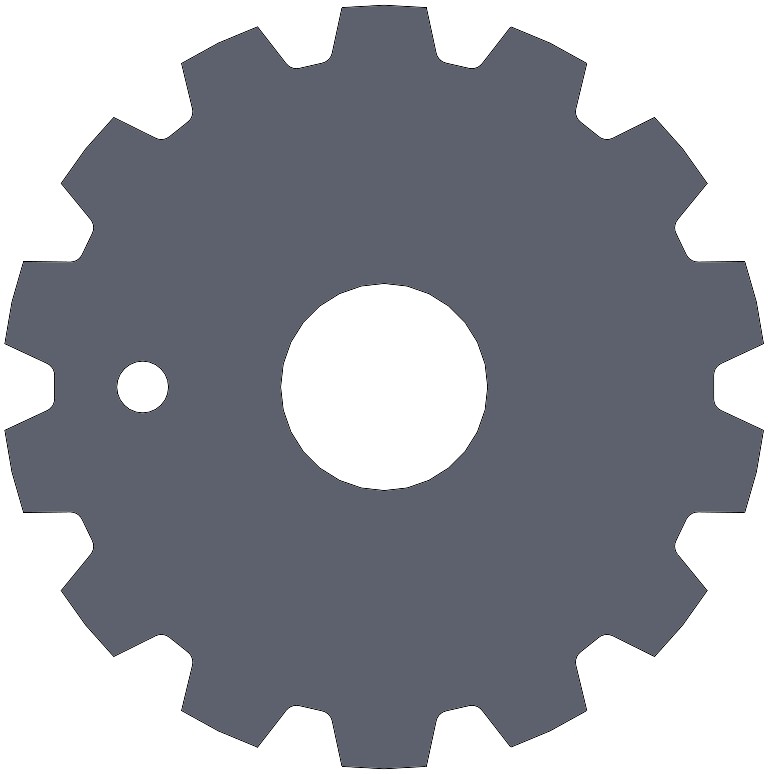

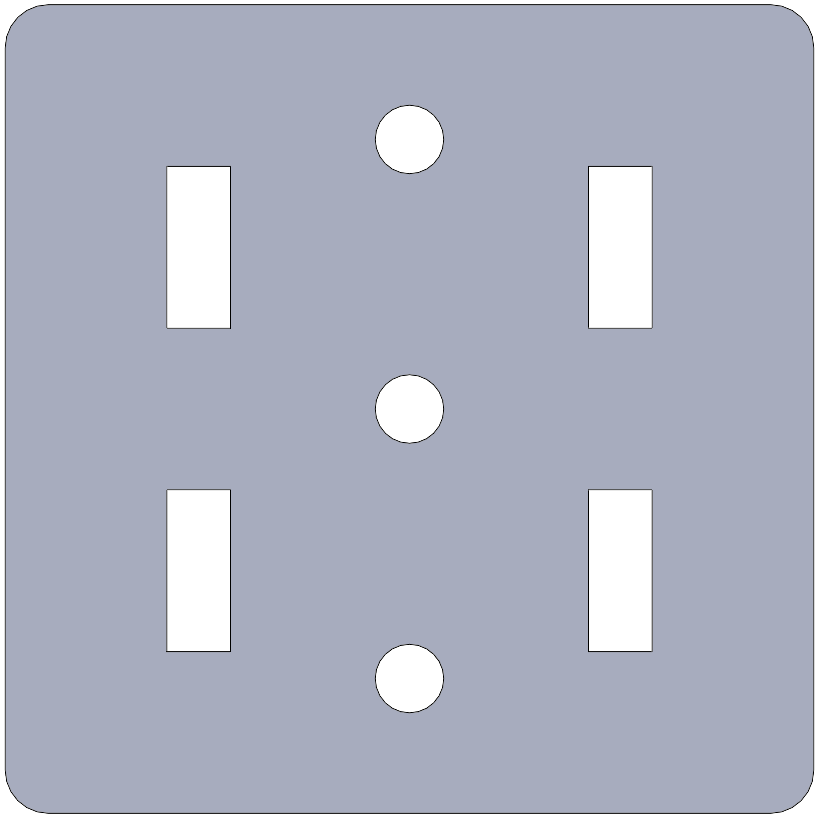

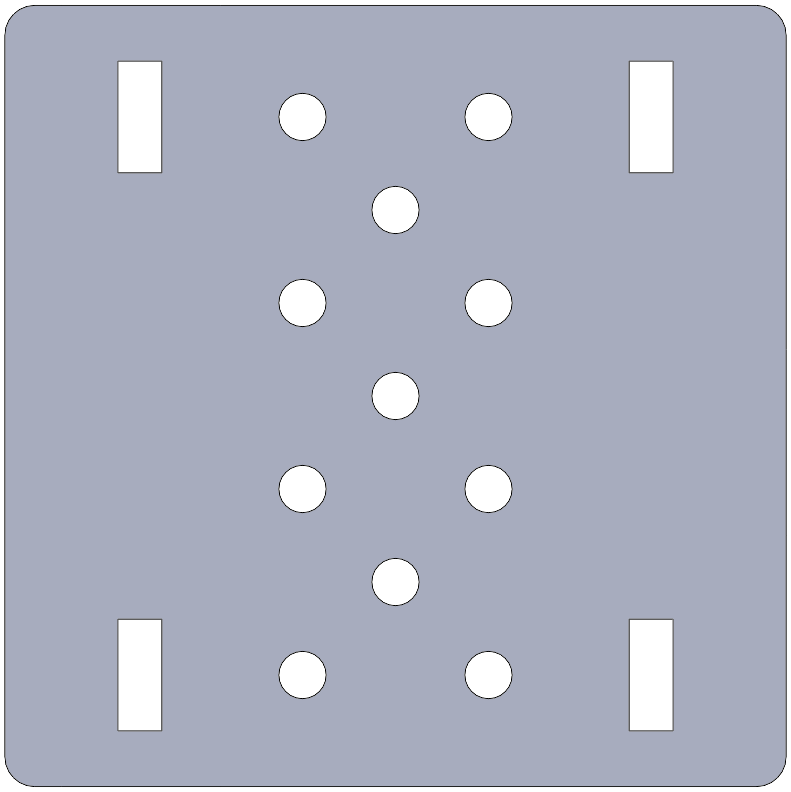

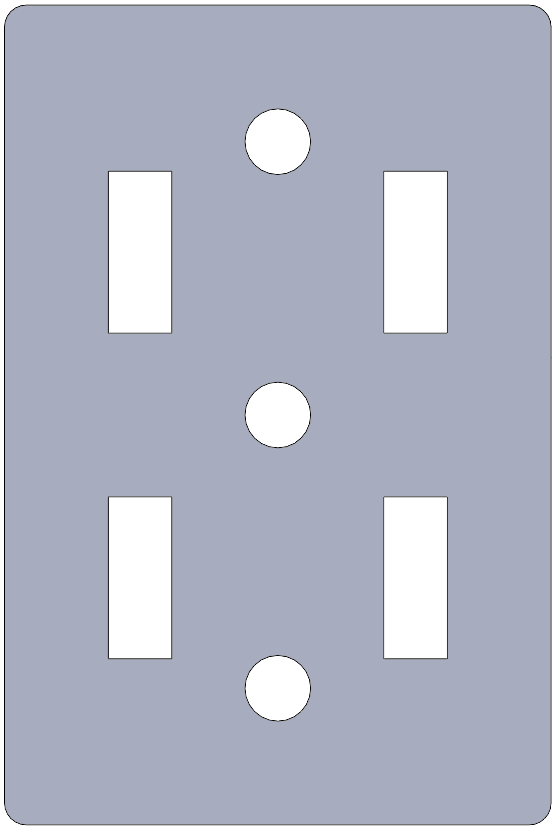

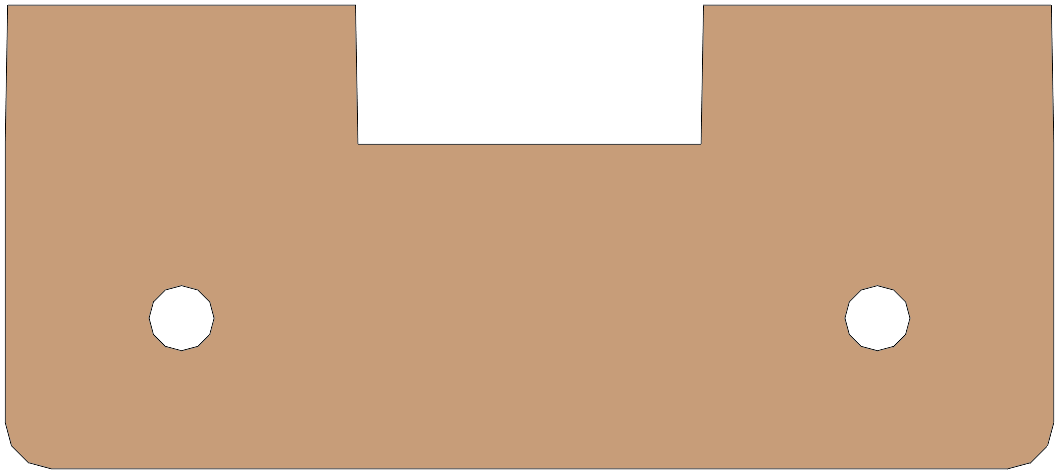

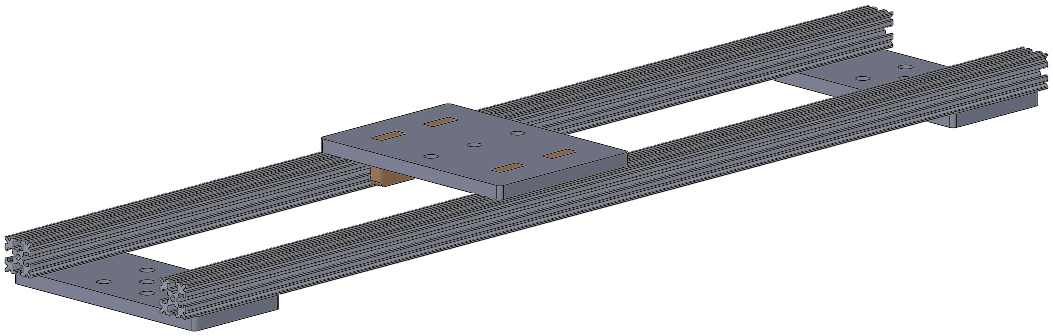

This example demonstrates making a low-precision stepper-driven translation stage using sliding contact. The bearing is formed by contact between a wooden slider and rails of 15mm aluminum extrusion, optionally enhanced with glued-on felt. A suitable drive option for a short stage is a rack and pinion gear with the motor carried directly on the slider. For a longer stage, a long open-ended timing belt driven from a motor at one end moves a lightweight carrier. Either result is a low-precision but low-cost laser-cuttable translation stage.

The SolidWorks model files may be found in the FlatPackExamples/Slider-Systems folder, or may be downloaded as a single file as Slider-Systems.zip.

The individual cutting files may be found in the FlatPackDXF/rail-system folder and are individually linked from the DXF File Index.