Here is how I actuated my servo syringe and pneumatic device:

No matter what configuration I put the servo horn and paper clip in, the servo would abruptly jolt upon turning on, bending the paper clip. I tried the servo with both the sweep and sine code, but the changes in my pneumatic device were almost imperceptible, even after pumping air into it beforehand.

I fiddled with the servo/syringe setup for an hour or two before moving on to the fabric/tendon line realization.

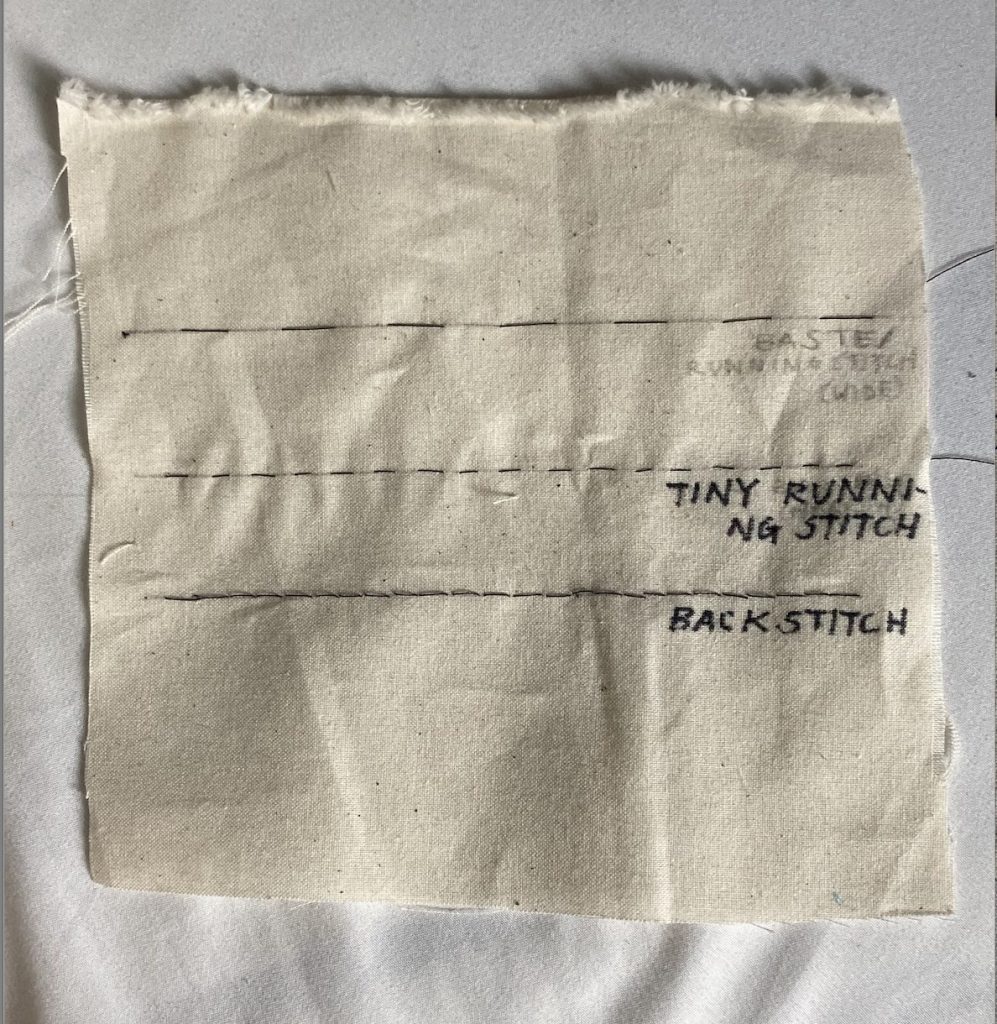

For the fabric/tendon line, I used a wide running stitch to ruche my swatch, and connected a thread from the edge of the swatch to the horn to slowly unravel the ruching. I found that the movement of the horn itself was not enough to flatten out the swatch, so if I used this method again, I’d have to incorporate some kind of technique to move either the servo motor or the swatch backwards. In this iteration, I occasionally scooted the fabric outwards.

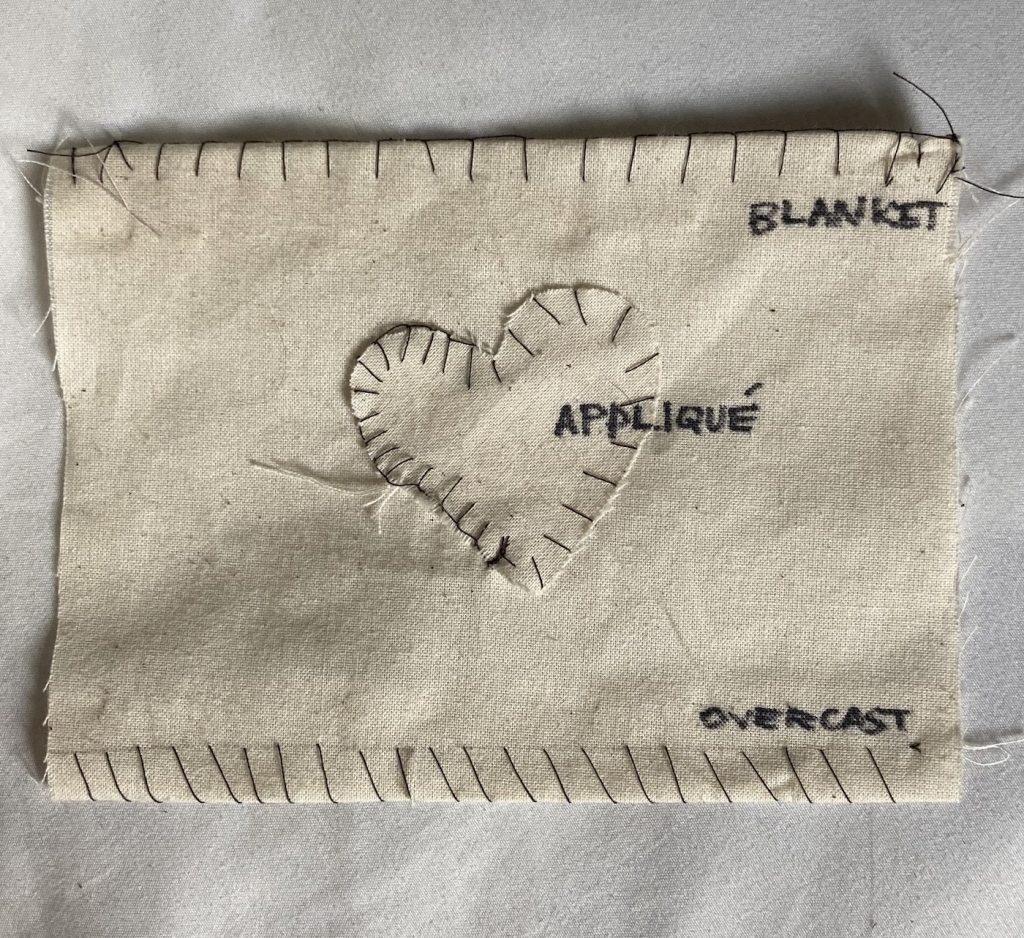

It was cool learning the terminology for the stitches. I unknowingly used the overcast stitch for my pressure sensor button. I’d never done a blanket stitch before, and for some reason, figuring out when to create loops and thread my string through them was kind of difficult, but we eventually got it!

Leave a Reply

You must be logged in to post a comment.