Results

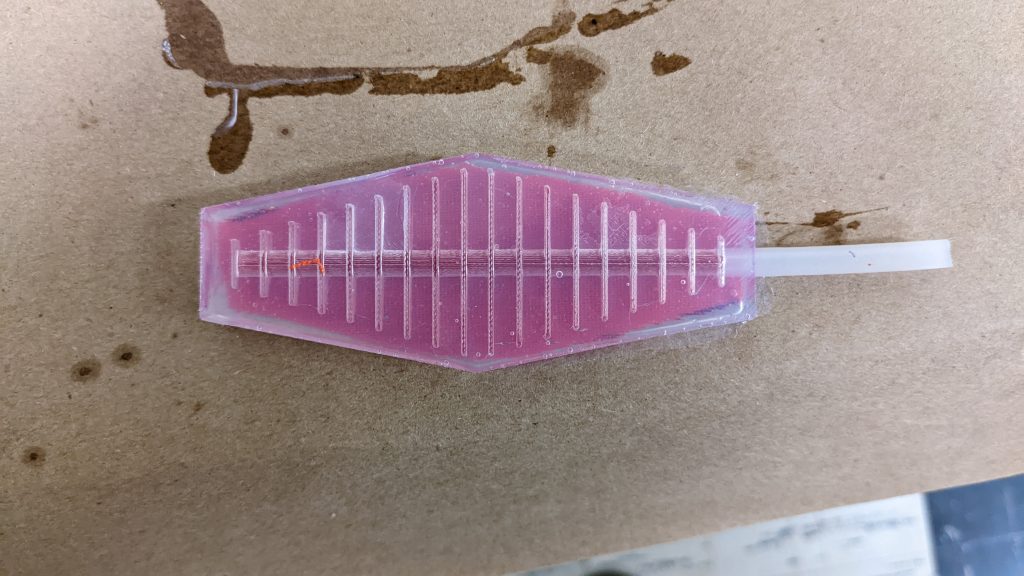

Jason: This latest iteration corrected many of the mistakes made during the previous iteration. The most drastic design change was the chamber designs. It retained the Whiteside’s thin chambers but with a two-millimeter gap between surfaces. The biggest change was in varying distances between the edge and angle with the chambers. This change was made to test how the varying lengths affect the actuation. Overall, the combination of the fabric and chamber geometry led to actuation with greater concavity. Unfortunately, one section did not bond well and caused a tear. However, this can be remedied by improving the process. The next steps are to create a central body unit and attempt a full body mold.

https://drive.google.com/drive/folders/1fxSou0ma5k9XlpAtVw6NzxqrmjjDLu85?usp=sharing