Welding

Basics of Welding:

Welding is the fusion of metal, where the base metal is melted and usually a filler metal is added to the pool of molten metal. Welding is advantageous because it creates a strong joining.

Types of Welding:

- Arc Welding

Probably the most basic type of welding, it uses an electrode to create an electric arc between the material and the electrode in order to generate the heat to melt the material.

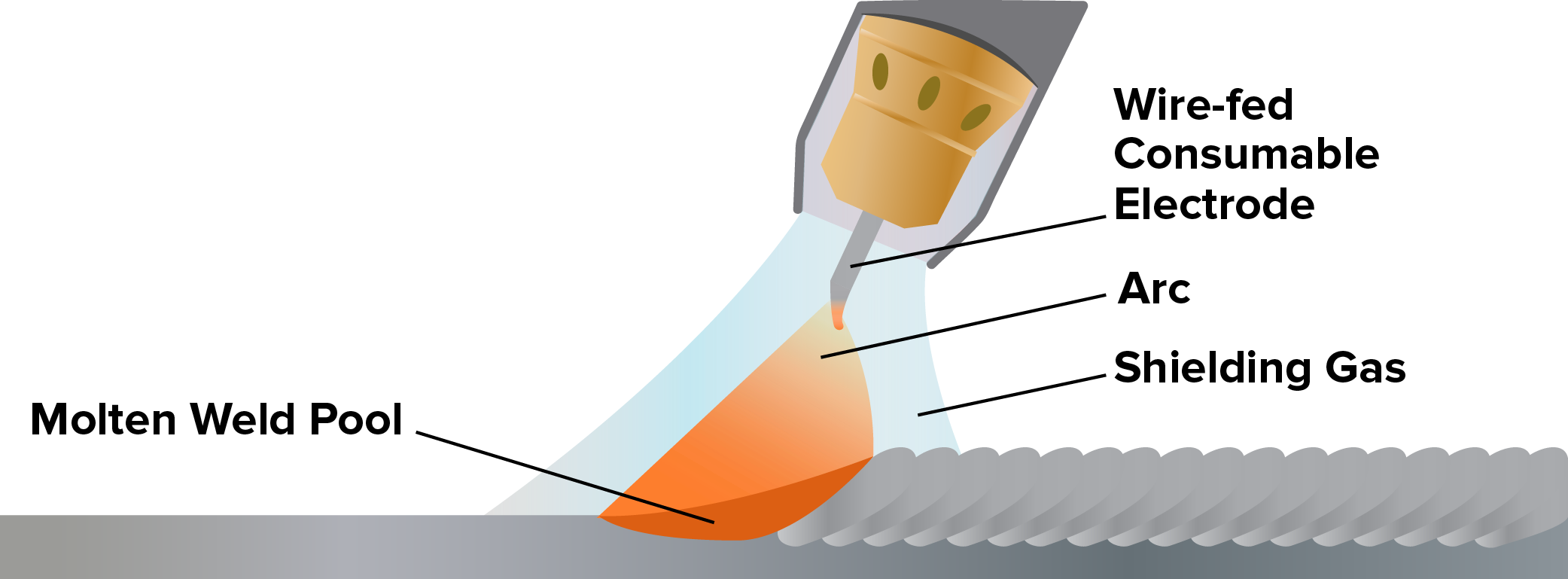

- Gas Metal Arc Welding (GMAW/MIG)

One of the most common types of welding, it is the most easily mastered and is used for welding mild steel, stainless-steel, and aluminum. MIG welding uses welding “gun” with a consumable electrode so an additional filler metal is not needed. A shielding gas, usually carbon dioxide or argon, protects the weld.

- Tungsten Inert Gas (GTAW/TIG)

TIG welding is similar to MIG welding, except that it uses a non-consumable tungsten electrode to weld requiring the need for a filler metal. It is used for higher quality work and takes greater expertise to do.

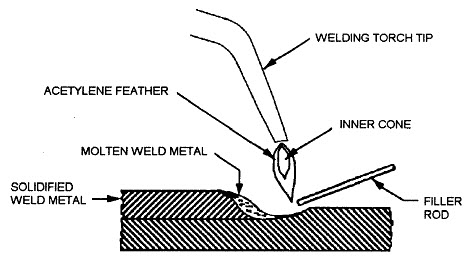

- Gas Welding

Uses gas to create a flame hot enough to melt most metals. Generally used today for welding copper and brass.

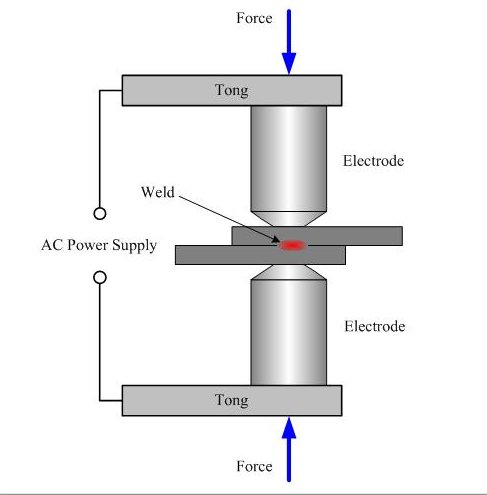

- Spot Welding

Spot welding is welding at small points using both electrodes and pressure. It is typically used for welding together very thin sheet metal.

Welding on Campus:

- Machine Shop: Hammerschlag Hall C124 – TIG/MIG Welding

- ArtFab: Doherty Hall D200A – 3 MIG, TIG, spot welding, gas welding, 3 arc welding

- 54-264: Welding for Drama Technical Direction majors. Open to non-majors if space available.

- Join CMR (Carnegie Mellon Racing) or FRC (Field Robotics Center)

Your best bet to having something welded is finding a friend who is very experienced in welding and has access to welding on campus.