Assembly is pretty self explanatory when put in the context of this class. One of the most important aspects of assembly are tolerances.

Tolerance: the permissible differentiation of the physical dimensions for a physical part. This can also apply for safety measures and distances.

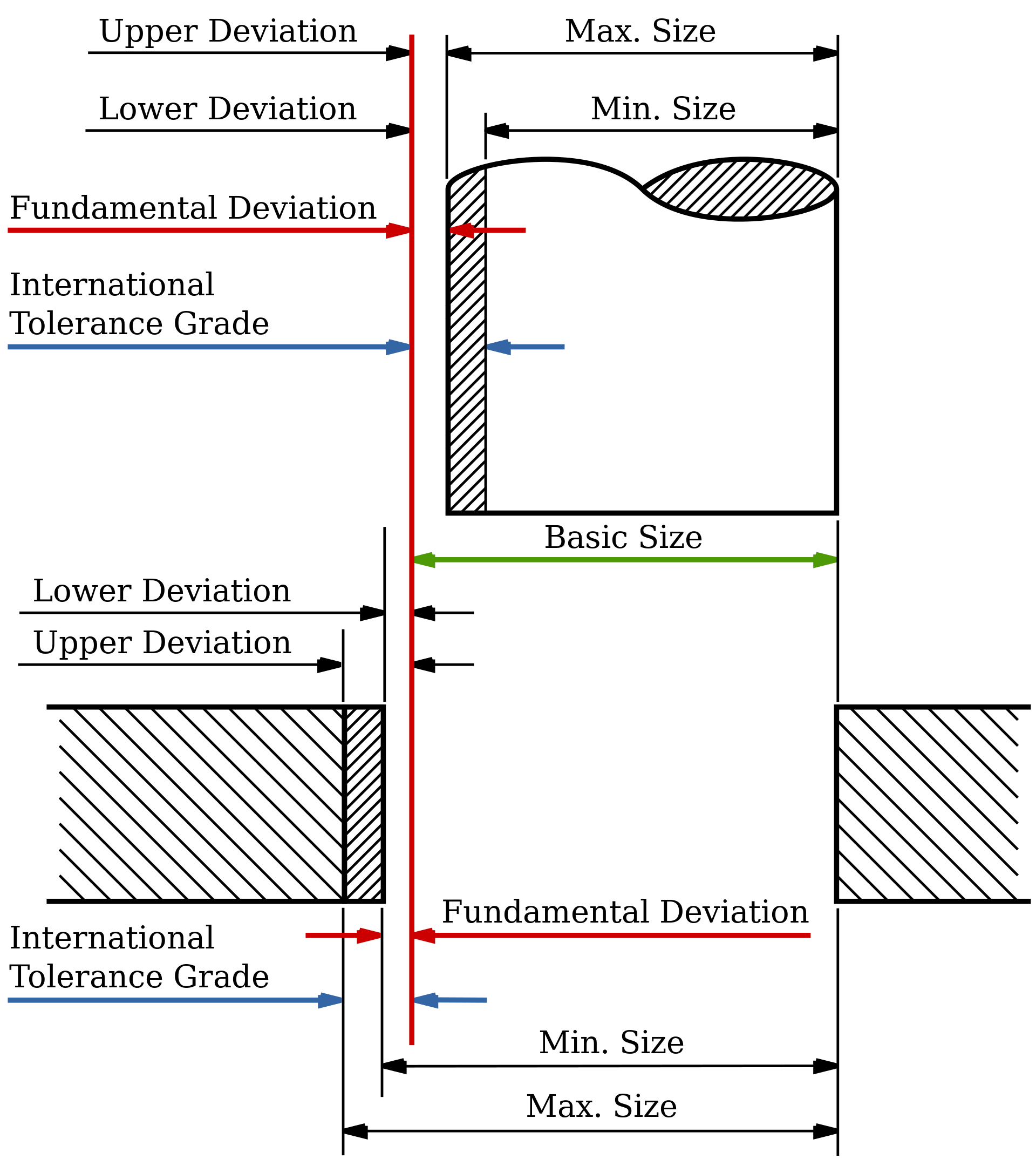

In this diagram you can see many defined distances (Defined by Engineering Tolerance on Wikipedia:

Basic size: The nominal diameter of the shaft (or bolt) and the hole. This is, in general, the same for both components.

Lower deviation: The difference between the minimum possible component size and the basic size.

Upper deviation: The difference between the maximum possible component size and the basic size.

Fundamental deviation: The minimum difference in size between a component and the basic size.

These tolerances are important for when you are assembling your part because they allow for different interactions between your parts.

Defined by Coban Engineering:

Clearance Fit: Type of fit in which one part fits easily into another with a resulting clearance gap.

This can be utilized in assemblies that require some movement. An example of this would be the interaction between a key and a door lock. The key is required to fit into the lock with little to no force in order to slide in and out.

Interference Fit: A type of fit in which one part must be forcibly fitted into another.

This fit would be used for parts that limit movement. Some examples of this can include Things that can deform to apply friction like screws, table legs, and pen caps.

Transition Fit: A type of fit in which loosest case provides a clearance fit and the tightest case gives an interference fit.

This fit can be used in non-mating assemblies like pistons and piston rings of IC engines.

These types of fit depend on your needs. Different materials deform differently and their yield stresses can cause the material to permanently deform and wear down over time.

GD&T Basics:

file:///C:/Users/s3chi/Downloads/GD&T%20Wall%20Chart.pdf

Talks about the four big things having to do with tolerances: form, size, orientation, and location.

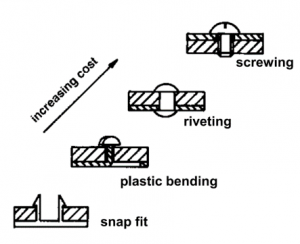

Types of part interactions:

Snap Fit: Uses flexible parts to deflect and catch into a depression in the part to keep it in place. Usually made of plastic. Lego products are a great example of a toy application.

Screws: Self explanatory.

Permanent Solutions: Glue, welding, and soldering are examples of more permanent/non-reversible ways to assemble objects.

Techniques for Assemblies:

Use symmetry: Reduces the chance for assembly error and also distributes forces evenly across a surface.

Account for loss of material: Material can be lost by cutting tools like saws and laser cutters.

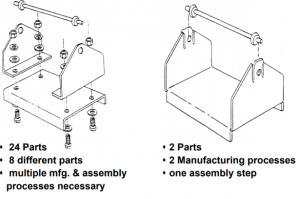

Decrease the number of parts: Reduces complexity and even can increase the strength of the object in some instances.

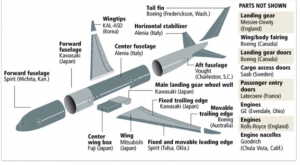

Modular designs: Assembling large and complex designs in pieces can allow for an easier assembly and better attention to detail.

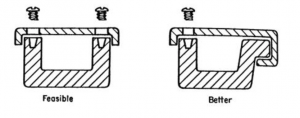

Reduce handling difficulty: Use parts that do not need to be realigned and slide into their places with little difficulty if possible. Also make sure that other components are not blocking other parts of the assembly.

Reduce Non-reversible processes: Welding, soldering, and gluing have practical uses, but while you are creating a design, these methods of attaching parts together can be hard to reverse and take apart. This is important to note if a design change occurs or access to internals is needed.

Places on Campus:

Anywhere with power tools (Hammershlag Makerspace, Architecture Woodshop, Design Woodshop)

3d Printing stations and Laser Cutters (IDeATe Makerspace, Morewood, Robotics Club, DFab)

Sewing Stations (School of Drama, Morewood)??

Video Links:

Bibliography/links:

https://en.wikipedia.org/wiki/Engineering_tolerance

uhttp://me.gatech.edu/files/capstone/L071ME4182DFA

uhttp://www2.mae.ufl.edu/designlab/DFMA%20Tips/DFMA%20Tips.htm

uhttps://activerain.com/blogsview/5168667/modular—genius

https://www.cobanengineering.com/Tolerances/TolerancesDefinitions.asp

3 Types of Fits-Clearance Fit,Transition Fit & Interference Fit,Selective Assembly