Forging is the process of heating, deforming, and finishing a piece of metal. There are many forms of forging such as open-die forging, impression die-forging, cold forging, and rolled ring forging. Each of these forging processes is specific for each of the pieces you want to create.

Open Die-Forging

Open die forging is performed between flat dies with no precut profiles Movement of the work piece is the key to this method. Larger parts over 200,000 lbs. and 80 feet in length can be hammered or pressed into shape this way.

Impression Die-Forging

Impression Die-Forging is the process by which the metal is shaped by two dies on the top and the bottom. These dies have specific shapes so when the metal is compressed it becomes the desired shape. This process is usually used for smaller parts compared to open die-forging.

Cold Forging

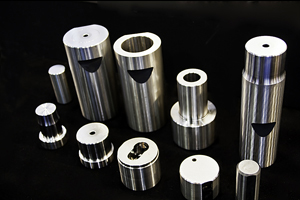

Cold forging encompasses many processes such as bending, cold drawing, cold heading, coining, extrusions and more, to yield a diverse range of part shapes. The temperature of metals being cold forged may range from room temperature to several hundred degrees. This process is used for more specific parts that have a lot of spaces and intricate designs. This is the most precise forging compared to all the rest.

Rolled-Ring Forging

Seamless rolled ring forging is performed by punching a hole in a thick, round piece of metal (creating a donut shape), and then rolling and squeezing (or in some cases, pounding) the donut into a thin ring. These rings can vary in size from 3-5 inches to 30 feet. It is usually used for bigger rings that can be used in big machines such as planes or buildings.

(https://www.forging.org/types-of-forging-processes)