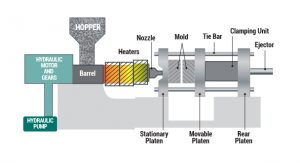

How Injection Molding Works:

- There is an injection molding machine with an injection molding tool.

- Plastic granulate is fed through a hopper and heated up.

- Hydraulic are use to push the plastic into the metal mold.

- Part is then cooled and ejected from the machine.

Should You Consider Injection Molding for Your Toy Project?

To answer this question several more questions have to be asked.

Do you need a large amount of that part?

If no than 3d printing probably will serve your use better.

Are you going through a lot of redesigns?

If yes than 3d printing is probably better because designing the mold for the laser injection molding takes a lot of time.

Injection molding is an extremely fast process, but most likely if you only need a small amount of custom parts 3d printing would be better because of its availability around campus. Also, the upfront work to get the injection molding to work is a lot more compared to making a part in CAD and downloading the STL.

Online Resources:

Comprehensive video by Davis Tech Injection Molding where they compare injection molding vs 3d printing.

Where the Process is Available on Campus:

There is an injection molding maching in Rothfus Lab (Undergraduate Lab) run by Matt Cline in the Chemical Engineering Department.

Rothfus Lab can be accessed through Doherty A100

As long as you have the mold and the plastic, the machine may be used on Mondays, Tuesdays, and Thursdays from 12:30-3:30 PM.