Introduction

After our initial meeting with Joseph, our design client, our team set to work on developing a prototype that focused on alleviating some of Joseph’s freezing symptoms as a Parkinson’s patient. Our prototype is a detachable cane accessory that features an LED light as a flashlight, a horizontal-line laser as a visual cue, and a mini vibrator as a haptic cue.

For more initial background on our project, please see our previous post: https://courses.ideate.cmu.edu/60-223/f2018/work/meeting-documentation-2/.

Product

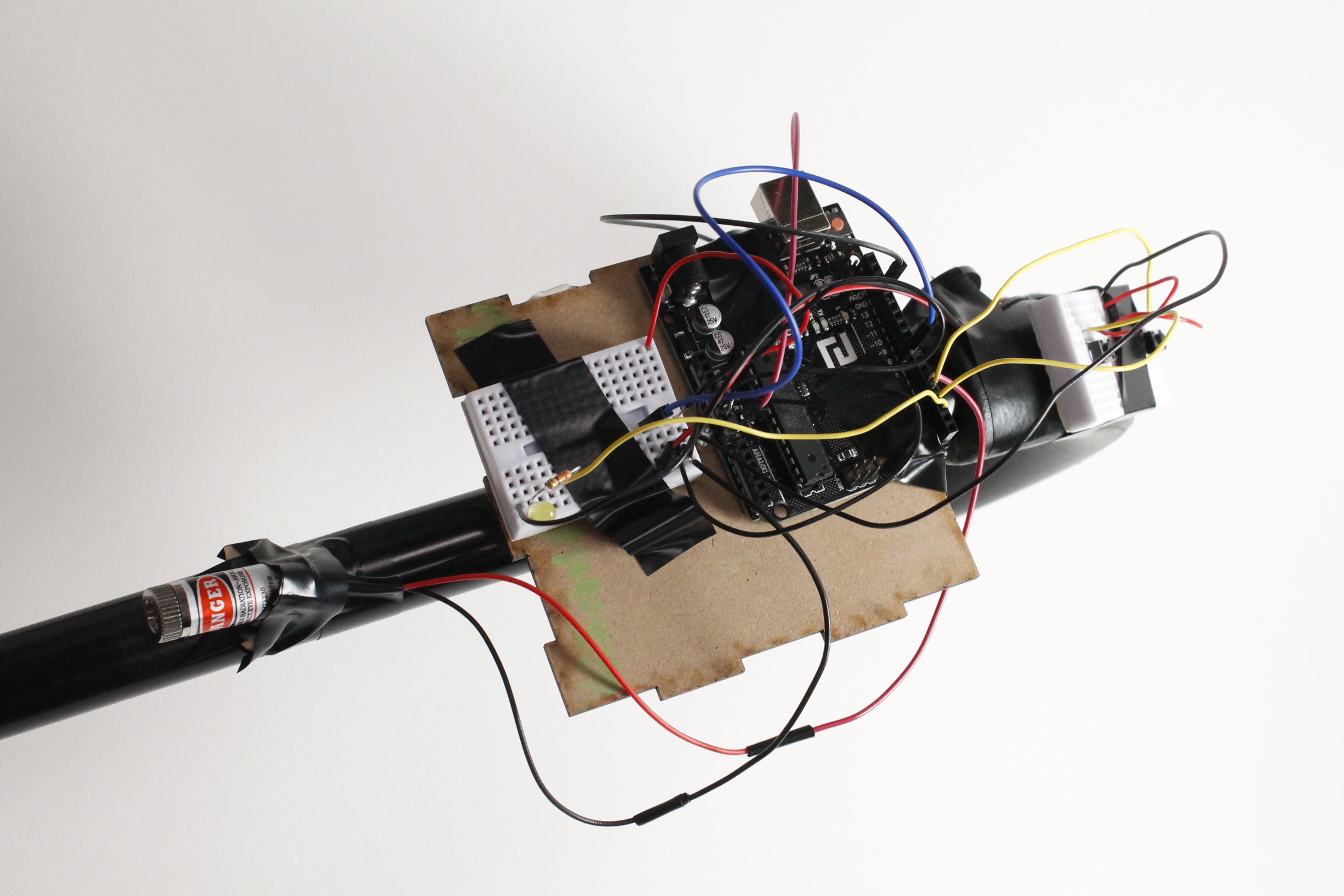

Our product is a detachable unit which clips onto any cane of our design client. In order to combat freezing episodes, or moments where Joseph loses his mobility, we have integrated a laser, which will project on to the floor ahead of him, when turned on through the use of a button. This laser will give Joseph a focal point to focus on, helping him break out of a freezing episode. In addition, the cane is equipped with a vibrating mini motor disc. When turned on via the same button as the laser, haptic cues are emitted at a consistent interval, subconsciously providing Joseph with a walking pace. Lastly, on our prototype, we have an LED substituting for a flashlight, which Joseph can turn on to increase visibility. The flashlight will have a separate button for its operations. Fortunately, our prototype has all of the functionalities of our final product, but does require refinement within these functionalities.

cane in use

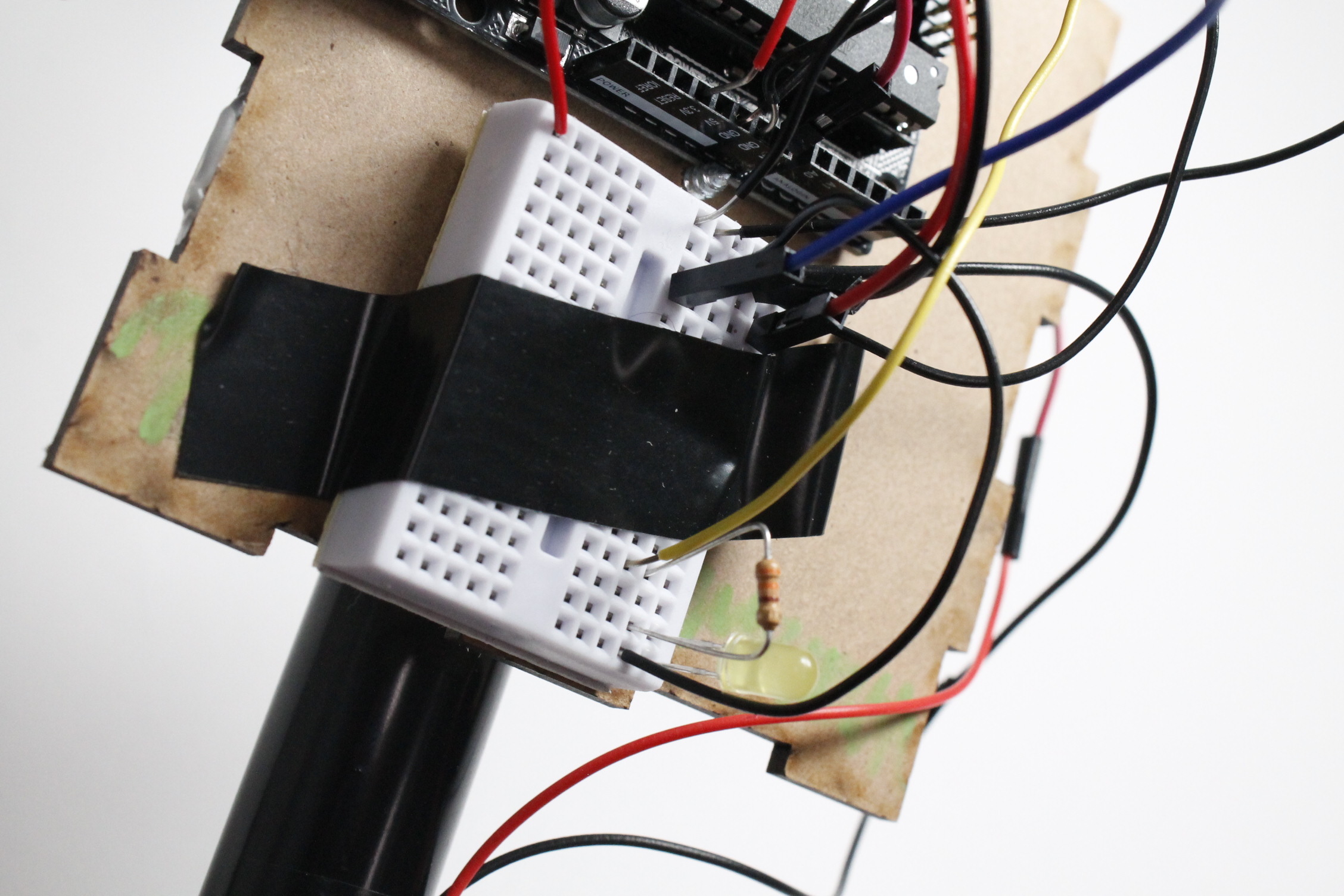

Overall details of prototype

the LED will be replaced by a flashlight at the end

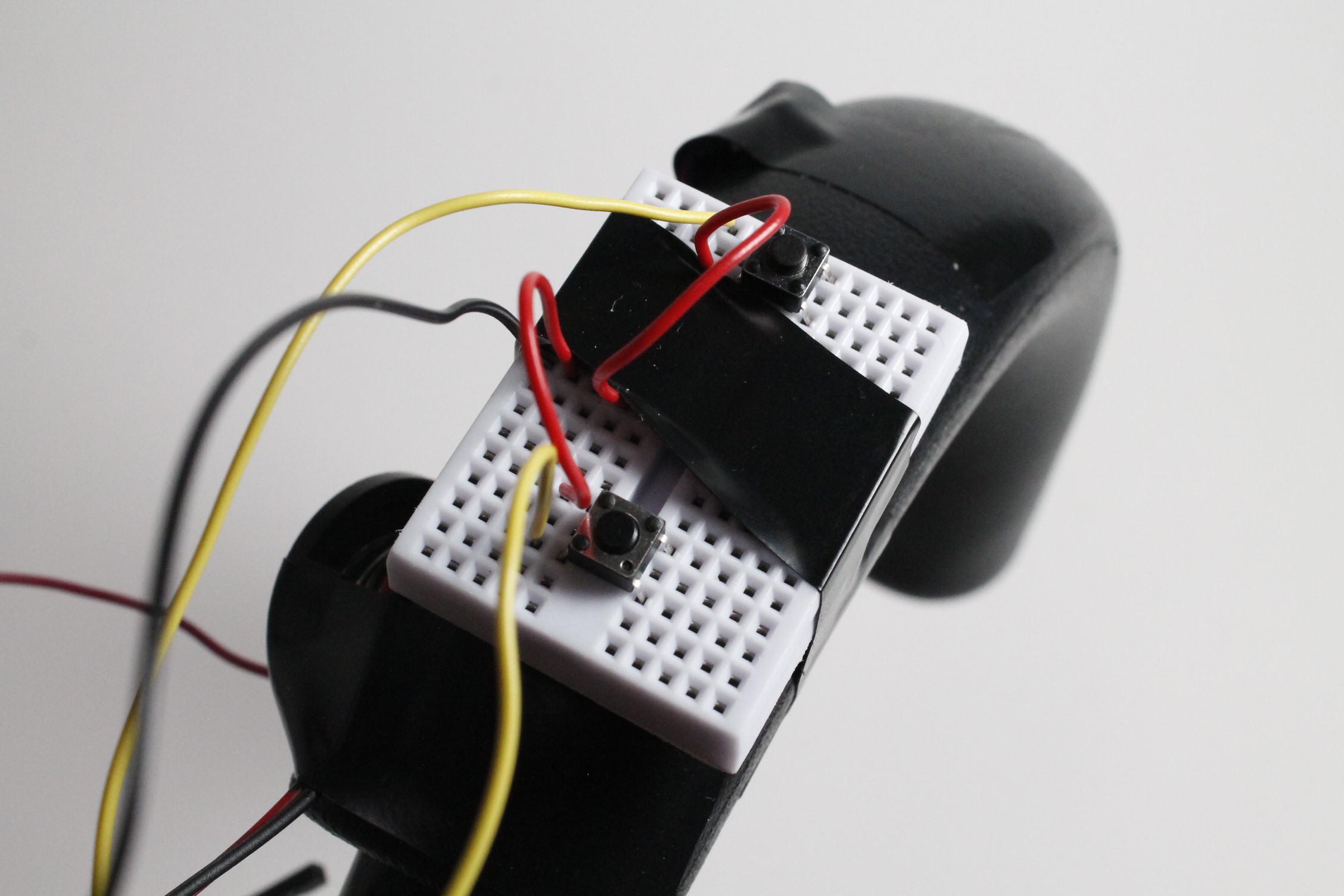

Details of buttons: upper one is for the cues, and the lower one is for the light

Details of laser: we angled it for the ideal distance between laser line and the cane

Process

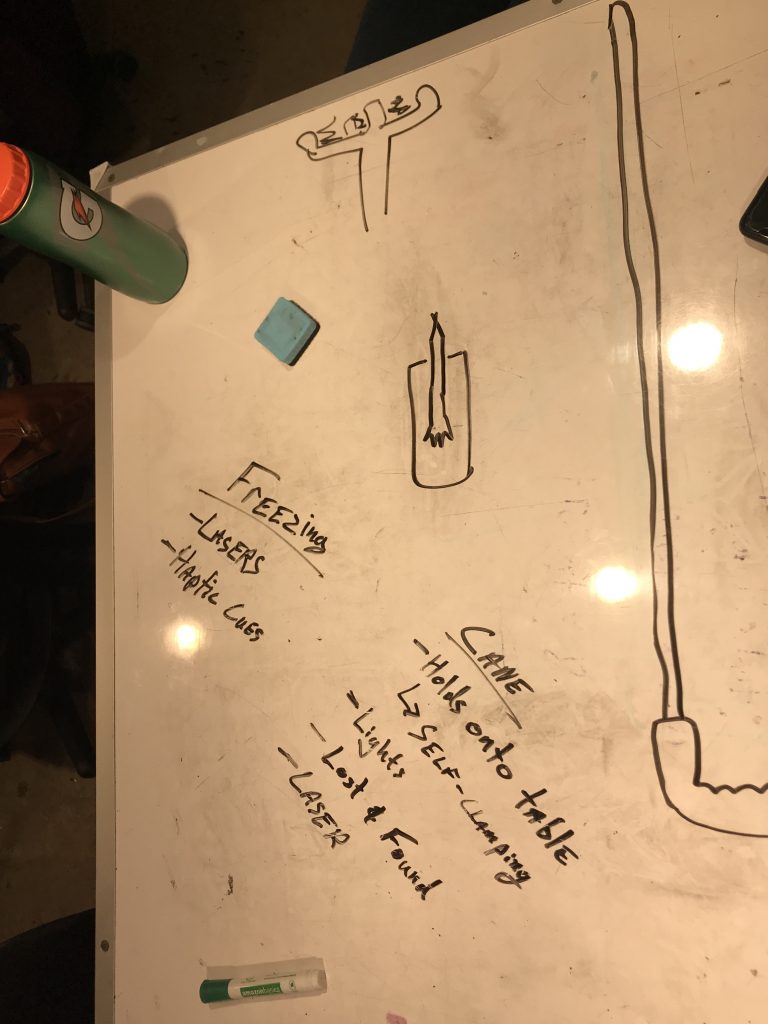

During an in-class work session, our team sat down and processed our initial meeting documentation with Joseph, researched different Parkinson’s symptoms, and brainstormed what kinds of technological solutions we could come up with involving an Arduino.

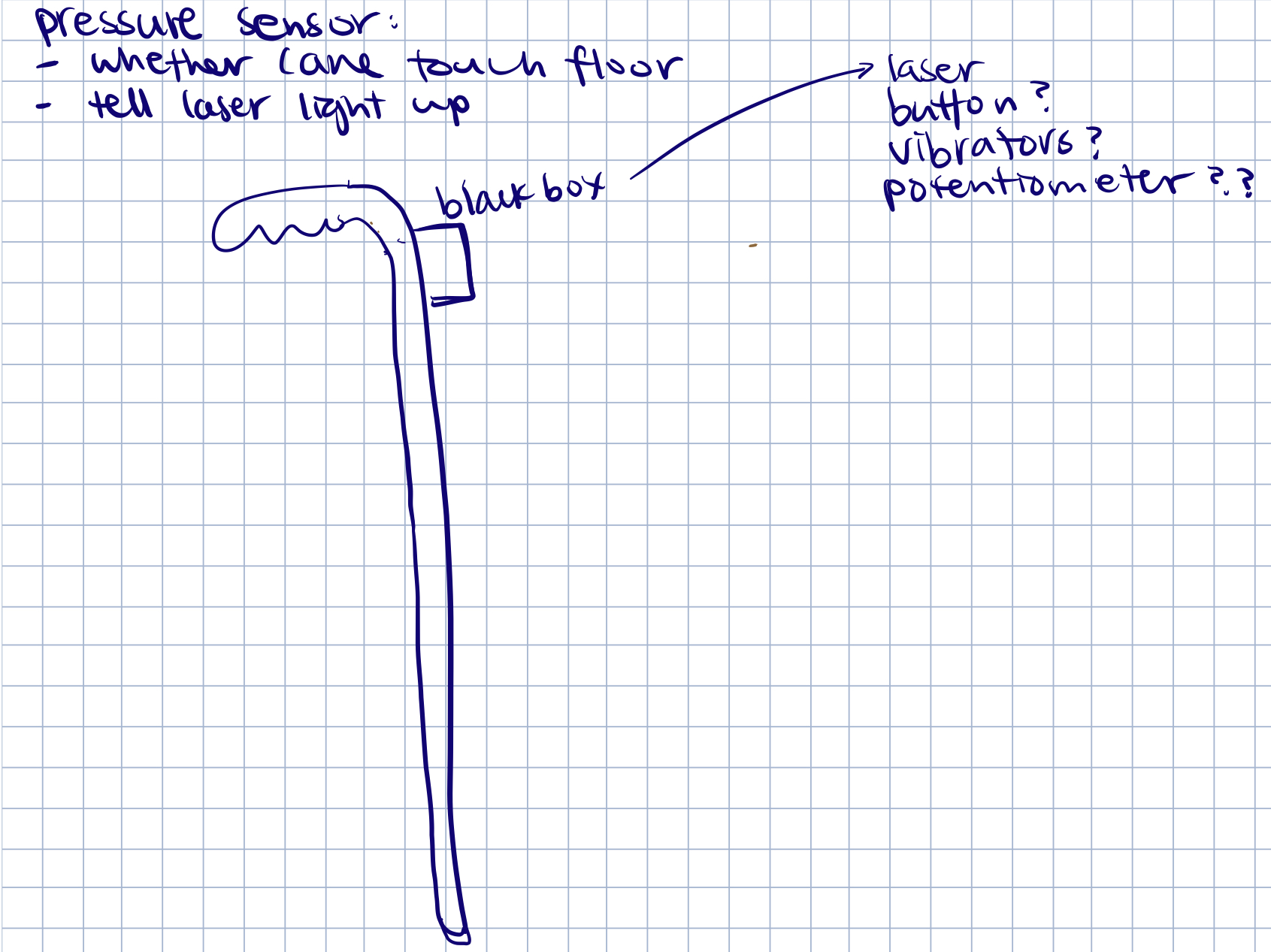

The earliest design which involves a pressure sensor at the bottom, but after talking to Joseph about his needs, we decided to take out the feature

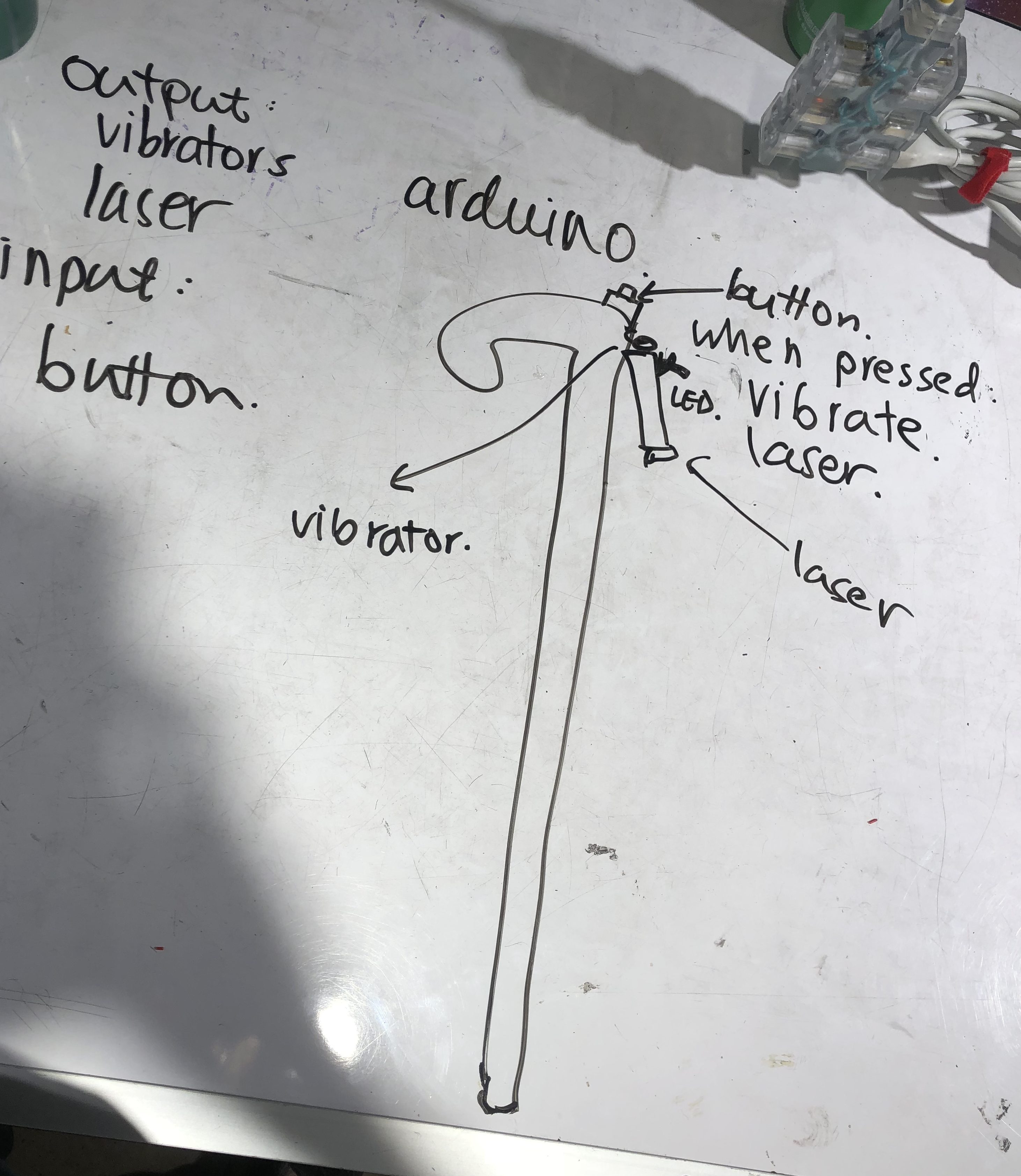

White board sketches of inputs and outputs

Whiteboarding our initial design helped us figure out how to design the hardware layout of the detachable cane accessory. We are smiling because prototyping is fun!

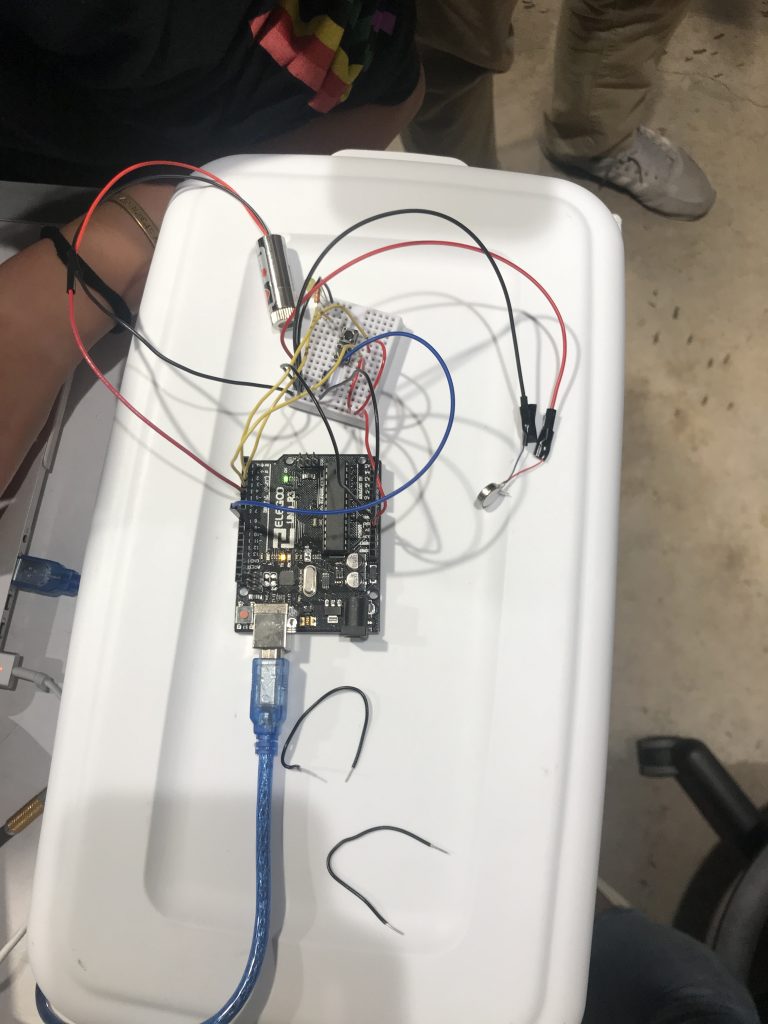

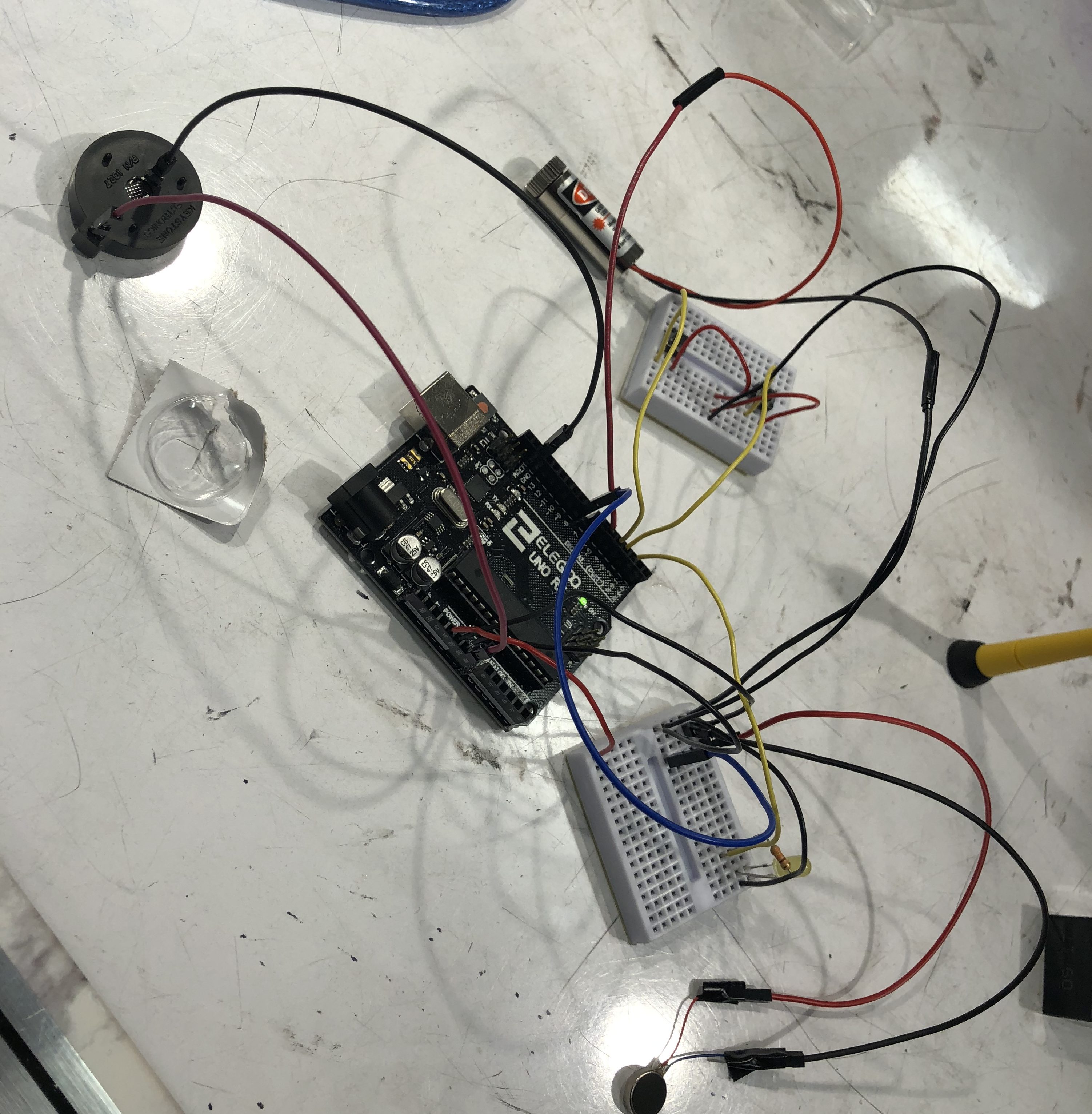

A very, very early prototype where we initially focused on getting different hardware components to work: the mini vibrator, the 3-5V red horizontal laser, controlled by two buttons.

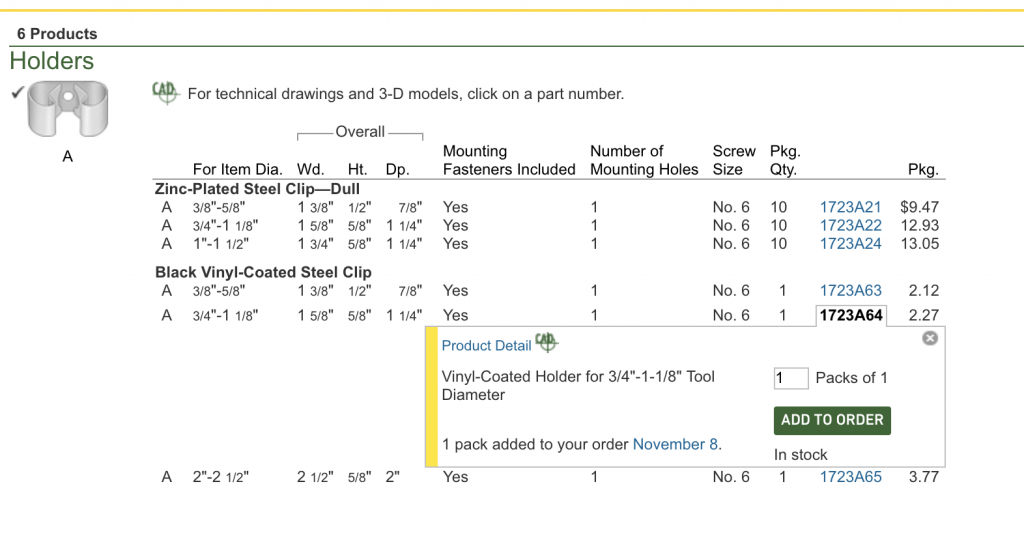

We purchased a black vinyl-coated steel spring clip that would act as the detachable accessory for Joseph’s canes. We measured the diameter of an example cane to be 22.55mm, or ~0.88″, and deduced that 0.75-1.125″ clips would be sufficient for most canes.

Hardware before attaching to the cane, powered by coin batteries

For our prototype, we strapped electrical tape to hold together the breadboards, Arduino, battery and laser to the cane.

Discussion

One of the major challenges during our prototyping process was the hardware design. Since Joseph consistently collects new canes and uses a wide variety of different canes for different purposes, our team wanted to create a detachable hardware solution that Joseph could snap onto any one of his canes (rather than just “hardcoding” it to one particular cane). We spent a fair amount of time changing the sizes of the breadboard and rearranging our circuitry such that it fit on a small piece of wood, which was then attached to a metal clamp that we ordered off McMaster. Additionally, because this is a detachable solution, we needed to fit all of the hardware components ideally in a single small box, high up near the handle of the cane such that Joseph could push buttons to turn on/off the haptic/visual cues. We considered creating two components that were detachable: one for the buttons high up near the handle, and another lower down for the laser; however after some user testing Joseph, he verified that the laser (although high up near the handle) still cast a visible enough light for him to follow.

On Tuesday, November 13, our team demonstrated our working prototype to Joseph and the class. We received several pieces of interesting feedback from the class; Sana notably questioned whether this detachable device would be TSA-friendly. This is a valid concern, because Joseph travels frequently to visit his son who lives in San Francisco, and while the detachable component is more travel-friendly, we would not want our older friend to get into trouble with the TSA unnecessarily. We will be looking into TSA regulations, particularly with respect to batteries, since certain types of batteries are prohibited on carry-ons.

What was particularly helpful was the one-on-one debrief we had with Joseph after our class demonstration.

Joseph tested out our assistive cane prototype and provided valuable feedback on additional customizations he would like.

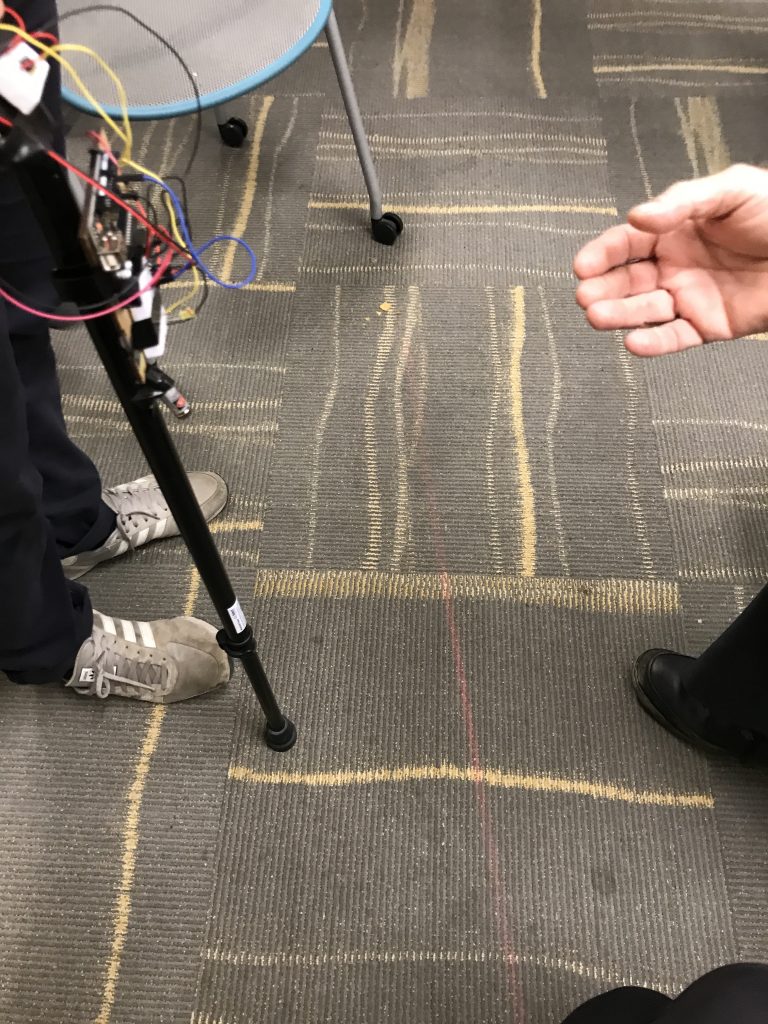

Some useful feedback that Joseph provided included: instead of having a horizontal laser that is perpendicular to his walking direction, he would prefer a vertical laser acts more like a forward “guide” pointing in the direction that he needs to walk. He said that he would likely respond better if the line was vertical. We plan on reorienting the laser such that it emits a vertical line instead.

As you can see, our prototype has a horizontal laser that is perpendicular to his walking direction. In this photo, Joseph discusses his vertical preference.

We also asked Joseph to provide feedback on whether he would be able to reach and physically press buttons to turn on the haptic and visual cues; in our prototype, one button triggers the LED “flashlight” and the other button triggers the haptic and visual cues (vibration and laser). One major design point that was brought up involved the placement of the button. Originally, our prototype had taped the button to the handle of the cane. However, given that Joseph has a multitude of different canes, which all have differently sized handles, attaching the buttons in this way would not be extensible for all of Joseph’s canes.

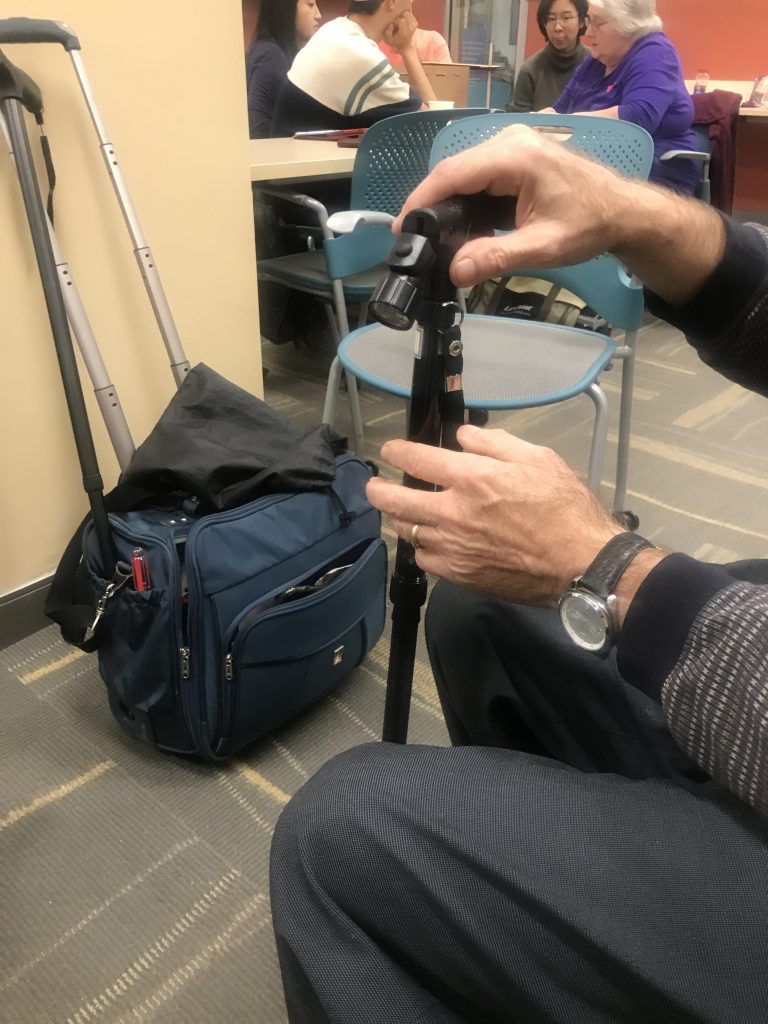

Joseph brought out one of his existing canes which has a flashlight attachment, which he bought off Amazon, and which he says that don’t work.

After discussing with Joseph on this matter, together we agreed that the buttons could be situated on the back of the detachable device’s box, because while his fingers are wrapped around the handle, he is still able to stretch them to comfortably press buttons a few inches away. Joseph also mentioned that he would like separate buttons to control the haptic and visual cues independently, as a matter of personal preference. From this critique, our team will create separate buttons for each cue, and place these buttons at the back of the detachable device’s box.

Talking to Joesph, he thinks we should get an A!

One thing that we learned from Joseph during our debrief is his planned usage of this detachable device. In his words, he said, “As the [natural] dopamine [in my brain] wears off, I need to take a synthetic dopamine pill.” During this time when his dopamine levels are low, Joseph is more prone to freezing episodes, in which he plans on using our device’s haptic and visual cues to aid him. He does not plan on frequently using this device every day, because he is concerned that the novelty of the cues will wear off and be ineffective in helping him get through freezing episodes.

Some other miscellaneous pieces of feedback that we plan on incorporating include:

- An on-off switch to power on/off the detachable device,

- A rechargeable battery or a battery that is compatible with TSA regulations

- An adjustable flashlight head

- Waterproof seal.

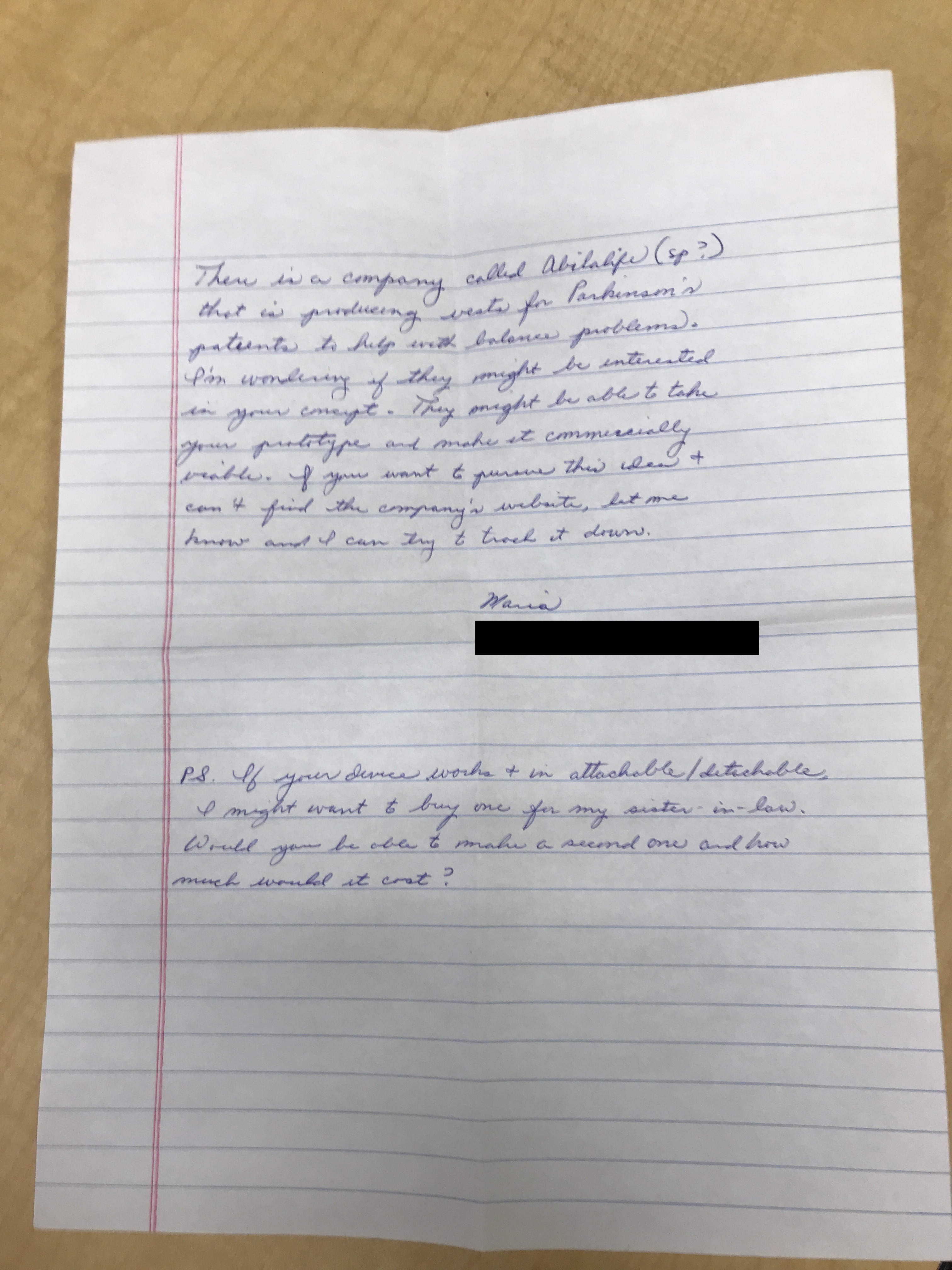

After our demo to the class, one of our other older friends, Maria (from another group), handed us a handwritten note. She was interested in our detachable device for her sister, who is also a Parkinson’s patient, and linked us to a company who may be interested in producing devices like these. (Email redacted for privacy purposes.)

For next steps, our team will focus on using a 9V battery (as opposed to the weaker 6V battery for our demo) and using a transistor to help power the laser, buttons, vibrator, and LED. The weaker 6V and 5V batteries we used could not supply enough current to power our device for a very long time. We also plan on using a smaller Arduino, like an Arduino Nano, to help reduce the size of the box that will contain all of the hardware components. Lastly, we will also begin looking into 3D-printing our box that will contain all the hardware components, so that it will be waterproof and customized. However, since none of our team members have experience with 3D modeling software, this may be a little out of scope. We also will work to incorporate Joseph’s feedback, like moving the buttons to the back of the detachable device box, using a brighter and larger LED, as well as ensuring our device is TSA-compliant.

Leave a Reply

You must be logged in to post a comment.