Introduction:

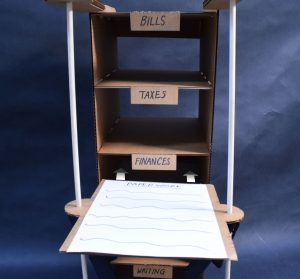

Our prototype of the Automatic Filing Machine! It is made of laser-cut cardboard and wooden dowels. The tray holding the paper is intended to move up and down to the correct shelf for filing.

A close-up of our paper tray. We did not have time to make the real-life representation of it, but the papers would have a conveyor belt underneath to move the papers off of the tray and into the shelf.

A very simple representation of our user interface: a button panel. Each button would be labeled with the shelf that it goes to, and maybe color coded to aid visual recognition.

We are team MARYa (Mohan, Andrea, Roly, and Yingyang), four students at Carnegie Mellon University that are assigned with the task to create a useful implement for our older friend, Maria. Previously, we had documented our meeting with Maria to find out what could be useful for her. In this stage, we took our idea and turned it into a prototype for Maria to see and critique at our next meeting with her, which was on November 13th. We found in our initial meeting with Maria that she needed was throwing her papers on the floor instead of filing them, so we tried to come up with a product that would organize her papers for her.

Product: An Automatic Filing Cabinet

Our prototype demonstrates a cabinet that files itself. Although it is completely a “behaves-like” prototype (it has no code yet), it does represent what our team envisioned for the product.

We want Maria to be able to put papers that she needs filed onto the tray of our product, press a button, and let the machine do the rest. The machine will determine where the papers go based on the button pressed, which corresponds to a shelf. The tray will move to that shelf, and a small conveyor-belt-like mechanism will push the papers onto the shelf. The tray would then return to the top of the machine, waiting for more papers. The buttons are located on top of the machine for easy access, and the front of the shelves are open to allow the user to take the papers they need out.

Process:

The origin of our idea: Maria’s very populated filing cabinets. She has a publishing business, and thus has massive amounts of paperwork.

A visual inspiration for the proportions and materials of our shelf. We like wood as a main material, since it would fit in well with Maria’s home. We also like the strength and customizability of it.

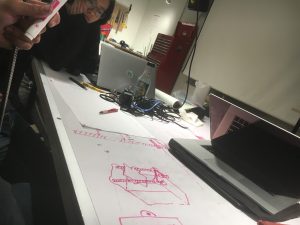

One of our most important meetings before the critique. Here Roly is explaining his vision of the mechanism for raising and lowering the paper tray.

One of the mechanism inspirations we found during image research. We will be using a stepper motor to spin a big threaded rod, but this required attaching the stepper to it using a belt. This image shows how we will do that.

A quick drawing that we used to determine how big our shelves should be. We needed to strike a balance between accessibility for Maria and accessibility for the Machine itself.

Maria’s first glimpses of the prototype! She was very intrigued with how it would work and gave some valuable input on the materials we should use and how our interface should be positioned.

The machine in action at our prototype meeting! Maria is testing the height of our paper tray and the reachability of the buttons.

Discussion

Our first meeting with Maria was much later than the other groups’, so we were a bit behind everyone else. While the rest of the class was working on the third in-class session for their prototype, our group was meeting Maria for the first time. Because of this, we only had around 4 days to meet up and work on a prototype. We couldn’t add any of the actual motorized or mechanical features of the prototype, but we did get a full-scale cardboard version of the prototype.

The crit on November 13th was pretty useful to our group. We met with Maria, and showed her our prototype. She gave us some useful feedback that we will want to incorporate into our final product.

She asked us to put wheels under it so that it could be moved easily, which I thought was pretty useful because none of us had thought about that. We asked her feedback on the placement of the buttons, and she gave us useful feedback for that as well, saying if we put the buttons on top of the shelf she wouldn’t be tempted to put things on top of it. She also asked us to number the shelves instead of writing labels on it so that she can label them herself and change the labels if she wants to, which I thought was something we should definitely consider.

For our next steps, we have a ton of work to do. We have to order our parts, figure out the mechanical and software aspects of this, finalize our design, cut the shelf itself out, and basically everything else. It will be quite a challenge to do this in 2 weeks especially with Thanksgiving break coming up, but hopefully we will pull it off.

Leave a Reply

You must be logged in to post a comment.