Clock Robot Model¶

The clock robot model simulates a large one-meter diameter analog clock with hour and minute hands. This model is intended as a demonstration testbed for single-axis control.

The hands are independently actuated with motors and have position sensors. The two hands have different inertia properties and so respond differently to the same control inputs.

The object geometry was modeled in Fusion 360 and exported as three STL files. The ‘bezel’ base does not participate in the dynamics, and none of the objects participate in collision. The mass properties were directly specified as computed by the CAD system.

This model is demonstrated in the clock-demo.wbt world.

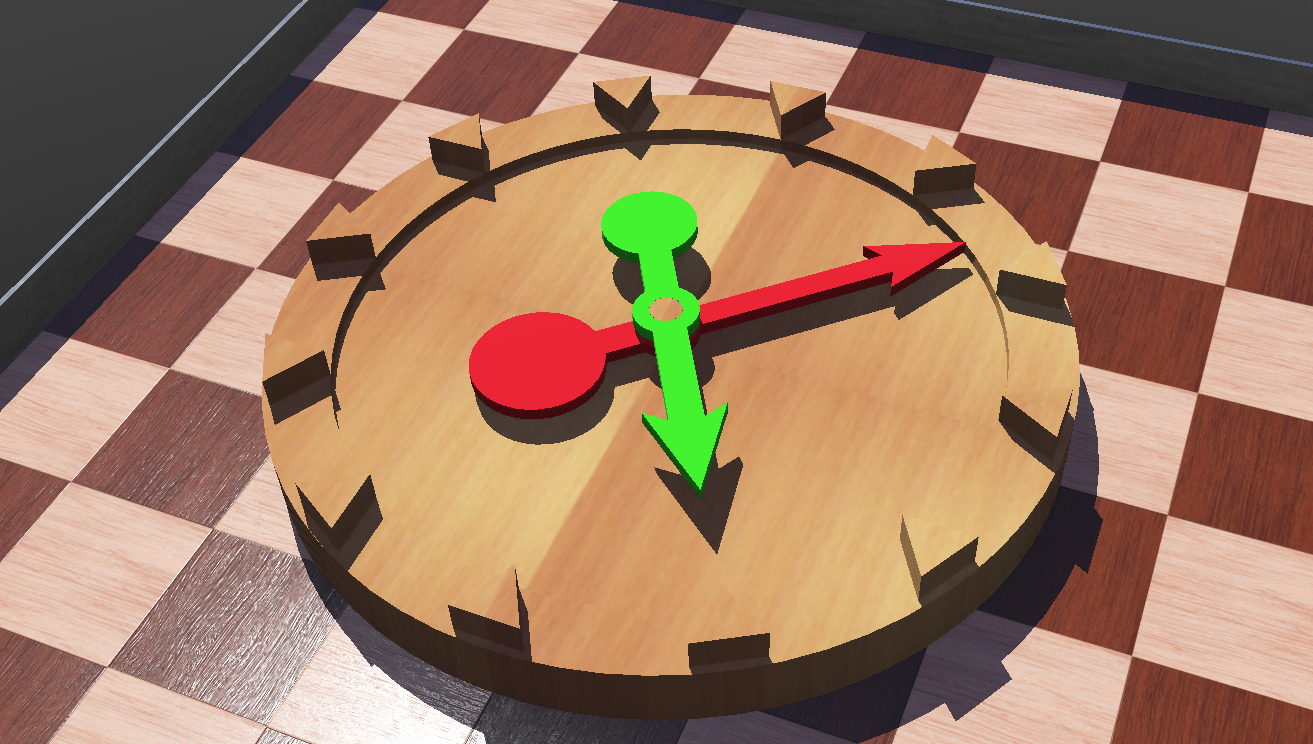

Screenshot of Webots model of clock with independently driven hour and minute hands. The robot is shown in the 5:08 position. The neutral pose is at 12:00, with positive joint angles increasing clockwise.¶

clock.proto¶

The clock model has been encapsulated in a .proto file for easy reuse.

1#VRML_SIM R2022a utf8

2# Large clock with hour and minute hands for course exercises. The bezel, hour

3# hand, and minute hand were drawn in CAD in the reference frame of the robot.

4# The object shapes were specified as external STL files, and object physics parameters

5# calculated by the CAD system. No bounding objects are specified.

6# The 'bezel' base does not have a physics node.

7# documentation url: https://courses.ideate.cmu.edu/16-375

8# license: No copyright, 2020-2022 Garth Zeglin. This file is explicitly placed in the public domain.

9PROTO clock [

10 field SFVec3f translation 0 0 0

11 field SFRotation rotation 0 1 0 0

12 field SFString controller "clock"

13 field SFString name "Clock"

14]

15{

16 Robot {

17 # connect properties to user-visible data fields

18 translation IS translation

19 rotation IS rotation

20 controller IS controller

21 name IS name

22

23 children [

24 DEF minuteJoint HingeJoint {

25 jointParameters HingeJointParameters {

26 axis 0 0 -1

27 dampingConstant 0.0

28 }

29 device [

30 PositionSensor {

31 name "minuteSensor"

32 }

33 RotationalMotor {

34 name "minuteMotor"

35 controlPID 4 0 0

36 maxTorque 0.5

37 }

38 ]

39

40 endPoint DEF minuteSolid Solid {

41 rotation 0 0 -1 0

42 children [

43 Transform {

44 children [

45 Shape {

46 appearance PBRAppearance {

47 baseColor 0.898787 0 0.0763561

48 roughness 1

49 metalness 0

50 name "DefaultMaterial"

51 }

52 geometry Mesh {

53 url [ "../stl/minute.stl" ]

54 }

55 }

56 ]

57 }

58 ]

59 name "minuteSolid"

60 physics Physics {

61 density -1

62 mass 0.789

63 centerOfMass [

64 0 -0.025 0.11

65 ]

66 inertiaMatrix [

67 0.039 0.001 0.041

68 0 0 0

69 ]

70 }

71 }

72 }

73 DEF hourJoint HingeJoint {

74 jointParameters HingeJointParameters {

75 axis 0 0 -1

76 dampingConstant 0.0

77 }

78 device [

79 PositionSensor {

80 name "hourSensor"

81 }

82 RotationalMotor {

83 name "hourMotor"

84 controlPID 4 0 0

85 maxTorque 0.5

86 }

87 ]

88 endPoint DEF hourSolid Solid {

89 rotation 0 0 -1 0

90 children [

91 Transform {

92 children [

93 Shape {

94 appearance PBRAppearance {

95 baseColor 0.141939 1 0.0408179

96 roughness 1

97 metalness 0

98 name "DefaultMaterial"

99 }

100 geometry Mesh {

101 url [ "../stl/hour.stl" ]

102 }

103 }

104 ]

105 }

106 ]

107 physics Physics {

108 density -1

109 mass 0.584

110 centerOfMass [

111 0 -0.019 0.14

112 ]

113 inertiaMatrix [

114 0.019 0.0005081 0.02

115 0 0 0

116 ]

117 }

118 }

119 }

120 DEF bezelSolid Solid {

121 children [

122 Shape {

123 appearance PBRAppearance {

124 baseColor 0.517 0.338 0.279

125 roughness 0.3

126 metalness 0

127 name "DefaultMaterial"

128 }

129 geometry Mesh {

130 url [ "../stl/bezel.stl" ]

131 }

132 }

133 ]

134 name "bezel"

135 }

136 ]

137 }

138}

Sample Clock Control Code¶

1# clock.py

2

3# Sample Webots controller file for driving the clock

4# model using torque mode and an implementation of a

5# linear PD controller on the two independent driven

6# joints.

7

8# No copyright, 2020, Garth Zeglin. This file is

9# explicitly placed in the public domain.

10

11print("loading clock.py...")

12

13# Import the Webots simulator API.

14from controller import Robot

15import math, time

16

17# Define the controller update time step in milliseconds.

18EVENT_LOOP_DT = 20

19

20# Specify proportional and derivative (damping) gains.

21P_gain = 0.10 # units are N-m / radian

22D_gain = 0.01 # units are N-m / (radian/sec)

23

24# Specify a soft torque limit. The underlying actuator

25# model is limited to a modest 0.1 N-m; this limits the

26# request to avoid error messages.

27max_tau = 0.1

28

29# Request a proxy object representing the robot to control.

30robot = Robot()

31robot_name = robot.getName()

32print("%s: controller connected." % (robot_name))

33

34# Fetch handles for the minute and hour hand motors.

35minute_motor = robot.getDevice('minuteMotor')

36hour_motor = robot.getDevice('hourMotor')

37

38# Enter torque motor on both motors; this bypasses

39# the Webots low-level PID controllers.

40minute_motor.setTorque(0)

41hour_motor.setTorque(0)

42

43# Fetch handles for the minute and hour hand sensors.

44minute_sensor = robot.getDevice('minuteSensor')

45hour_sensor = robot.getDevice('hourSensor')

46

47# Specify the sampling rate for the joint sensors.

48minute_sensor.enable(EVENT_LOOP_DT)

49hour_sensor.enable(EVENT_LOOP_DT)

50

51# The controller estimates velocities using finite

52# differencing of the position sensors; these variables

53# hold the previous state.

54last_minute_angle = 0

55last_hour_angle = 0

56

57# Fetch the current wall clock time.

58now = time.localtime(time.time())

59

60# Convert time to initial hand motor angles in radians.

61initial_minute_angle = (now.tm_min % 60) * (math.pi/30)

62initial_hour_angle = (now.tm_hour % 12) * (math.pi/6)

63

64# Generate some debugging output

65print("%s: initial joint angles: minute: %f, hour: %f" % (robot_name, initial_minute_angle, initial_hour_angle))

66debug_timer = 2.0

67

68# Run loop to execute a periodic script until the simulation quits.

69# If the controller returns -1, the simulator is quitting.

70while robot.step(EVENT_LOOP_DT) != -1:

71

72 # Read simulator clock time and calculate new position targets based on elapsed time.

73 sim_t = robot.getTime()

74 target_minute = initial_minute_angle + sim_t * (2*math.pi / 3600) # one rev per 3600 seconds (hour)

75 target_hour = initial_hour_angle + sim_t * (4*math.pi / 86400) # two revs per 86400 seconds (day)

76

77 # Read the current sensor positions.

78 minute_angle = minute_sensor.getValue()

79 hour_angle = hour_sensor.getValue()

80

81 # Estimate current velocities in radians/sec using finite differences.

82 d_minute_dt = (minute_angle - last_minute_angle) / (0.001 * EVENT_LOOP_DT)

83 d_hour_dt = (hour_angle - last_hour_angle) / (0.001 * EVENT_LOOP_DT)

84 last_minute_angle = minute_angle

85 last_hour_angle = hour_angle

86

87 # Calculate new motor torques, limit them, and apply them to the system.

88 tau_minute = P_gain * (target_minute - minute_angle) - D_gain * d_minute_dt

89 tau_hour = P_gain * (target_hour - hour_angle) - D_gain * d_hour_dt

90

91 tau_minute = min(max(tau_minute, -max_tau), max_tau)

92 tau_hour = min(max(tau_hour, -max_tau), max_tau)

93

94 minute_motor.setTorque(tau_minute)

95 hour_motor.setTorque(tau_hour)

96

97 # Occasionally issue a message for debugging.

98 debug_timer -= 0.001*EVENT_LOOP_DT

99 if debug_timer < 0.0:

100 debug_timer += 2.0

101 print("%s: motor torques: minute: %f, hour: %f" % (robot_name, tau_minute, tau_hour))

Hour Hand Parameters¶

Each object was modeled in the neutral pose position, so the center of mass respect to the center of the bezel base. Physics parameters as computed by Fusion 360:

Volume |

8.678E-04 |

m^3 |

Density |

673.00 |

kg/m^3 |

Mass |

0.584 |

kg |

Physical Material |

Oak, Red |

Center of Mass: 0.00 m, -0.019 m, 0.14 m

Moment of Inertia at Center of Mass (kg m^2)

Ixx = 0.019 |

Ixy = 0.00 |

Ixz = 0.00 |

Iyx = 0.00 |

Iyy = 5.081E-04 |

Iyz = 0.00 |

Izx = 0.00 |

Izy = 0.00 |

Izz = 0.02 |

Minute Hand Parameters¶

Each object was modeled in the neutral pose position, so the center of mass vector is with respect to the center of the bezel base. Physics parameters as computed by Fusion 360:

Volume |

0.001 |

m^3 |

Density |

673.00 |

kg / m^3 |

Mass |

0.789 |

kg |

Physical Material |

Oak, Red |

Center of Mass: 0.00 m, -0.025 m, 0.11 m

Moment of Inertia at Center of Mass (kg m^2)

Ixx = 0.039 |

Ixy = 0.00 |

Ixz = 0.00 |

Iyx = 0.00 |

Iyy = 0.001 |

Iyz = 0.00 |

Izx = 0.00 |

Izy = 0.00 |

Izz = 0.041 |