Dyani Robarge & Jack Fogel

project context | motivation | scope | implementation

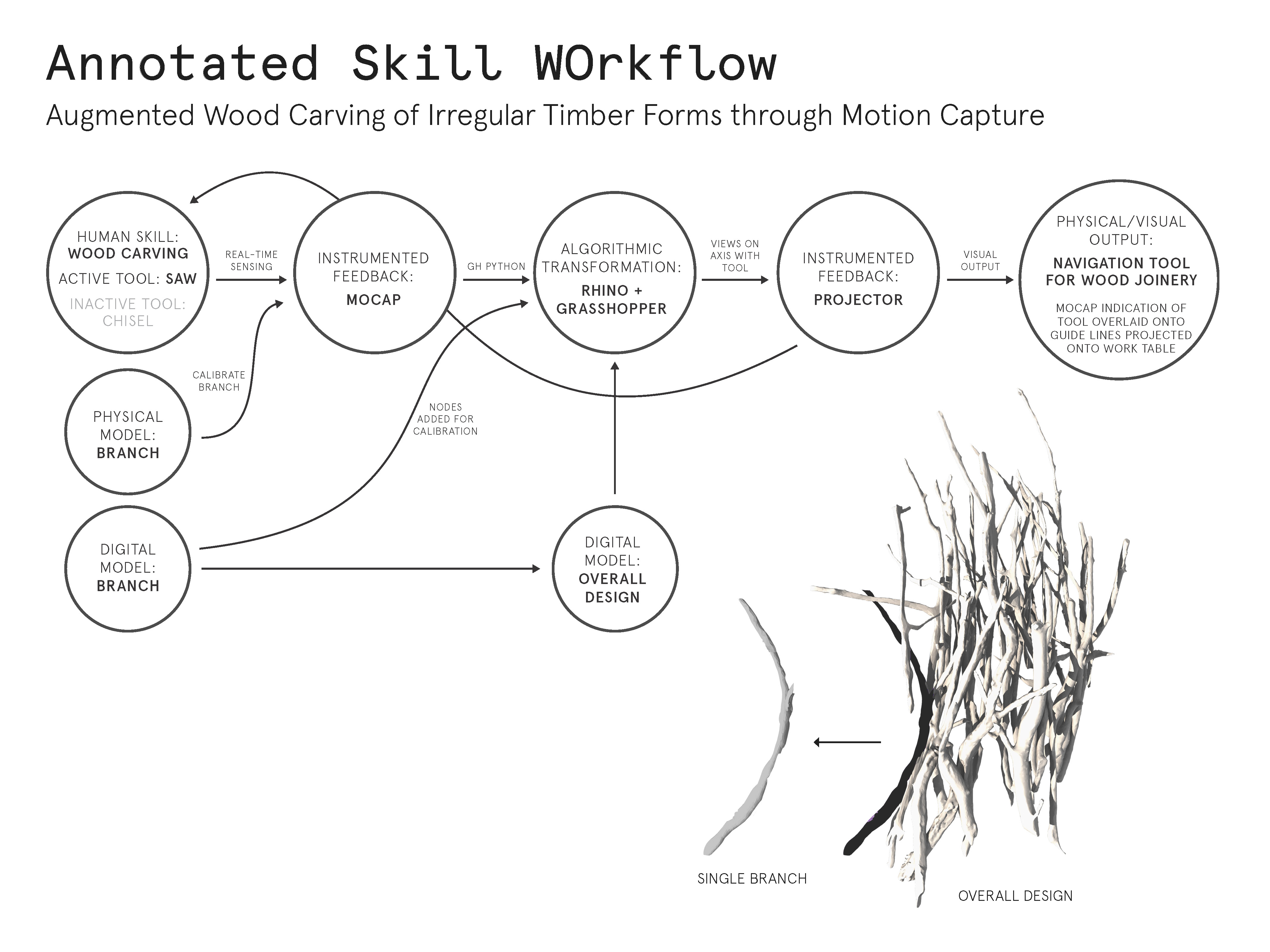

The system our team is developing harnesses the learned skill of woodcarving and applies this trade to an augmented assembly process. Specifically, the project seeks to augment the process by which individual branches are carefully carved.

VIDEO: Wood Carving Half Lap Joint with Hand Tools

The first step in this process is the tagging and reality capture of the branches. This process yields a digital representation of each physical branch used in the overall design. The clear resolution of each branch’s unique features in their digital representations allows the designer to mark each physical and digital model with three nodes. Each branch is set as a rigid body within the system. In addition, the carving saw is also set as a rigid body. Once this set-up is complete, the worker is ready to begin carving.

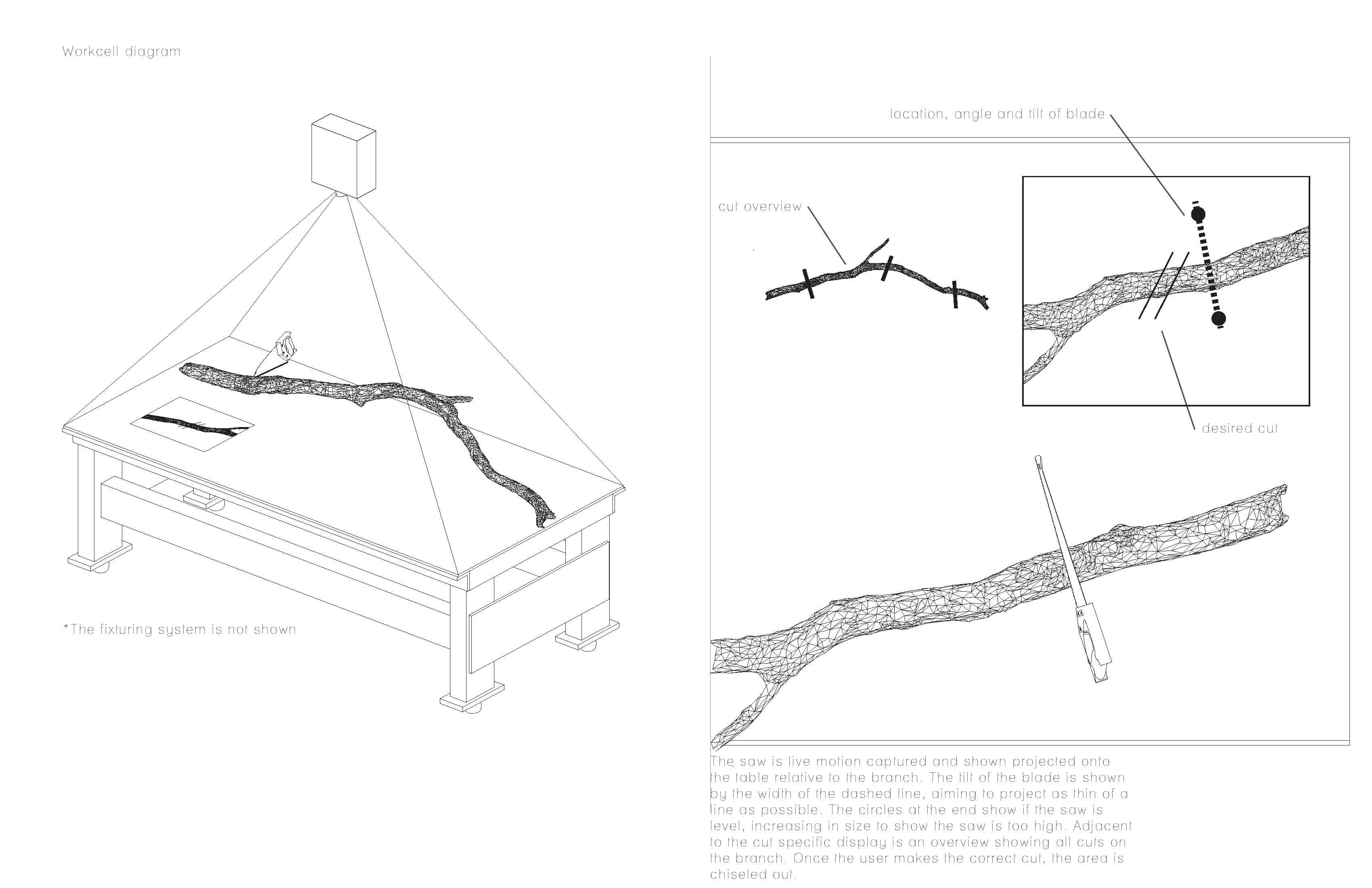

As a branch moves into the work cell, its tag appears on table’s projected screen. The worker then affixes the branch to the table’s fixture system, making sure to keep the carve areas visible and without obstruction. Once this branch is securely fastened, the wood carver introduces the saw to the work area and prepares to make the first alignment cuts. Lines projected onto the work table beside the wood carver help he or she align the tool in space and give clear indication of the correct saw angle when approaching each carve.

The system acts as a guide by relaying real-time feedback of the tool’s movements through space. By giving agency to the artist, they are free to decide when the visual cues are useful and when their attention is needed elsewhere in the work cell. This method of augmented working leaves complete freedom of the wood carve itself to the artist. We prefer the flexibility of augmented craftsmanship over automation because it allows for creative decisions to be made throughout the production process.

Our team plans to begin creating this system by setting up the table fixture and testing various motion capture markers on the branches. While prototyping, we will continue working on the code which links the work cell, branches and tool to the digital model. This abstracted visual of the augmented process is crucial to the overall workflow. We plan to refine the projected visuals so that the wood carver is able to work seamlessly while interpreting information needed to complete the piece.