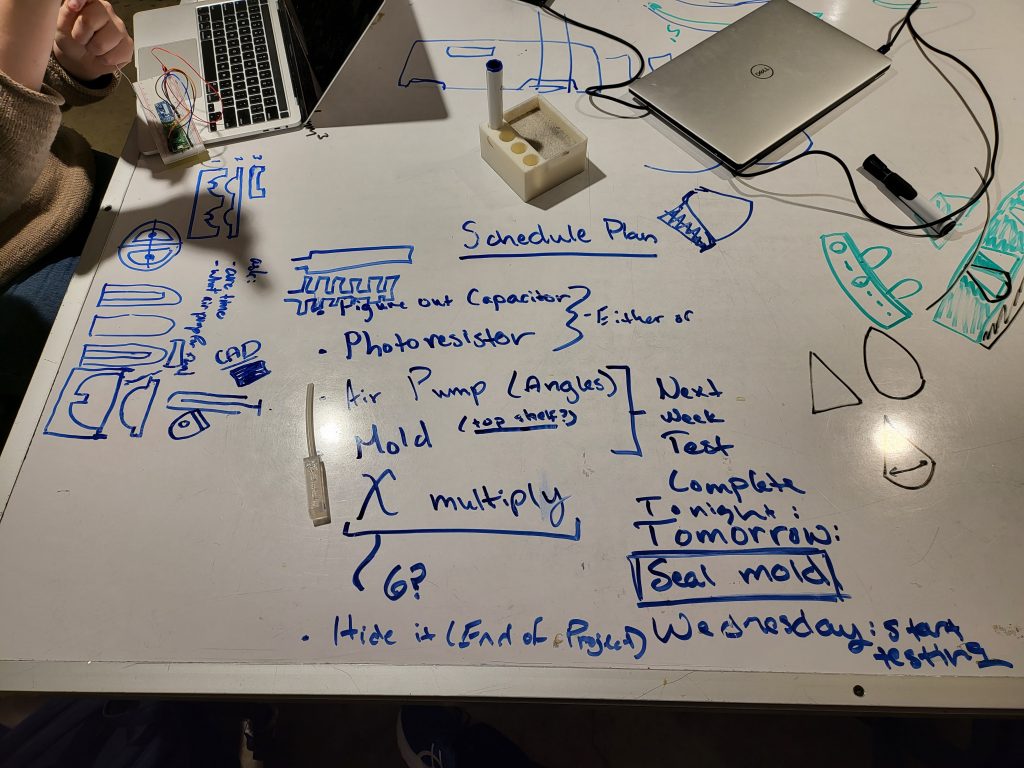

This week we tested our first version of our silicon anemone and we made progress on programming and circuiting the electronics. We originally planned to print our newest version of the mold, but since the 3D printers were down, we had to postpone our plans.

Monday, 3.20:

- Check cast and sealing, success!

- Note: this prototype likely will not work for directional pnematics

- Seal two halves together

- Continue creating mold

- Finished the coding portion: capacitive wire will sense touch (not squeeze FINALLY)

Tuesday, 3.21:

- Check casting and sealing, success

- Sealed together the other two halves with a wire in between for future sensitivity testing

Wednesday, 3.22:

- Finished mold

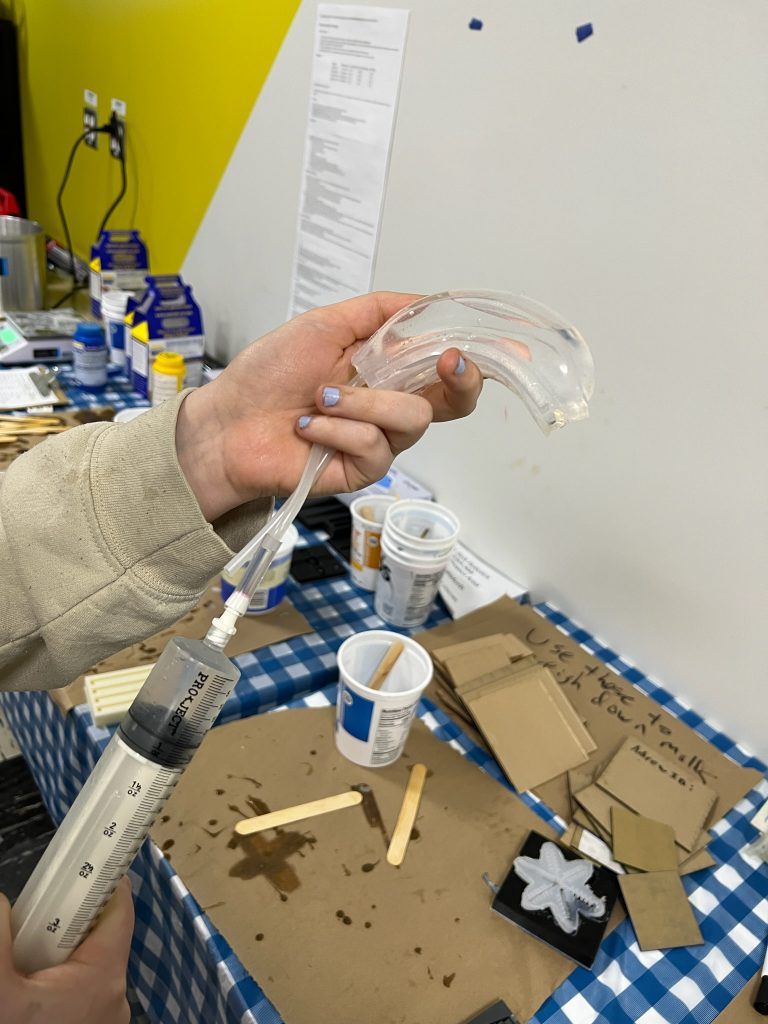

- Tested blowing up 2 channel cast

- Reference to above note: DOES work for directional pneumatics. Requires a lot of air for a significant bend, but does work.

- Test sensitivity code with two channel cast + wire embedded in silicon

- Raw threshold: 0

Sunday, 3.26:

- Worked on circuiting and programming the MOSFET driver, slow progress.

- Wrote this process log post 🙂