This week focused on model validation, with 4 casts in our 3D printed molds taking place. We used the Dragon Skin 20 for each of these pours, which is the same silicone that we used in our second cast. We chose a few models to cast – curved, missing link, and two-material. We also changed some line widths and densities to see how those factors impact behavior.

For our designs, we were able to start getting morphed geometries out of Rhino and Grasshopper. This was done using an attractor point, which was able to deform our auxtetic mesh. We are going to print and cast a couple of those this week.

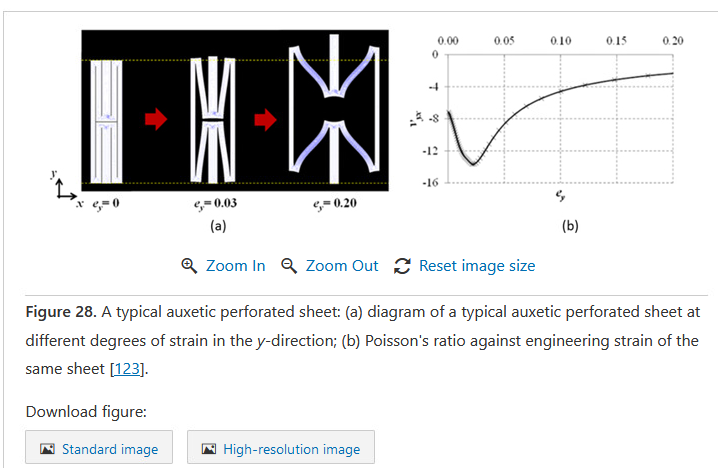

Finally, we encountered a new auxetic design that appears to have a lot of potential for visual appeal. This design starts almost entirely solid, but can expand to many times its size using its cutout design (literature has the v at around -14 for some configurations and loads). We are aiming to spend this week working on making this design somehow, which presents its own challenges.

With only a few weeks left, we also are starting to work on the user interface system design. Since this will take a few days of work to complete, we are going to start designing and sourcing parts this week in case anything needs to be ordered.