Alice’s Board

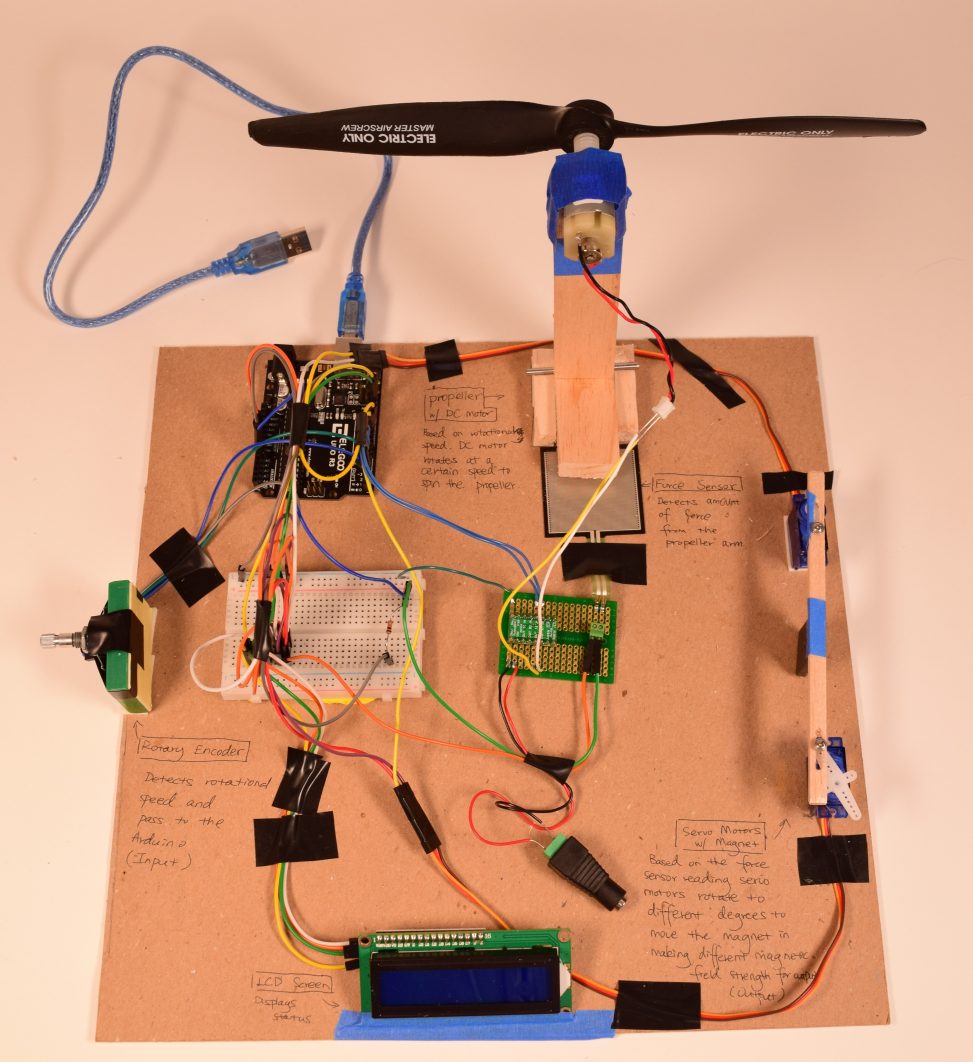

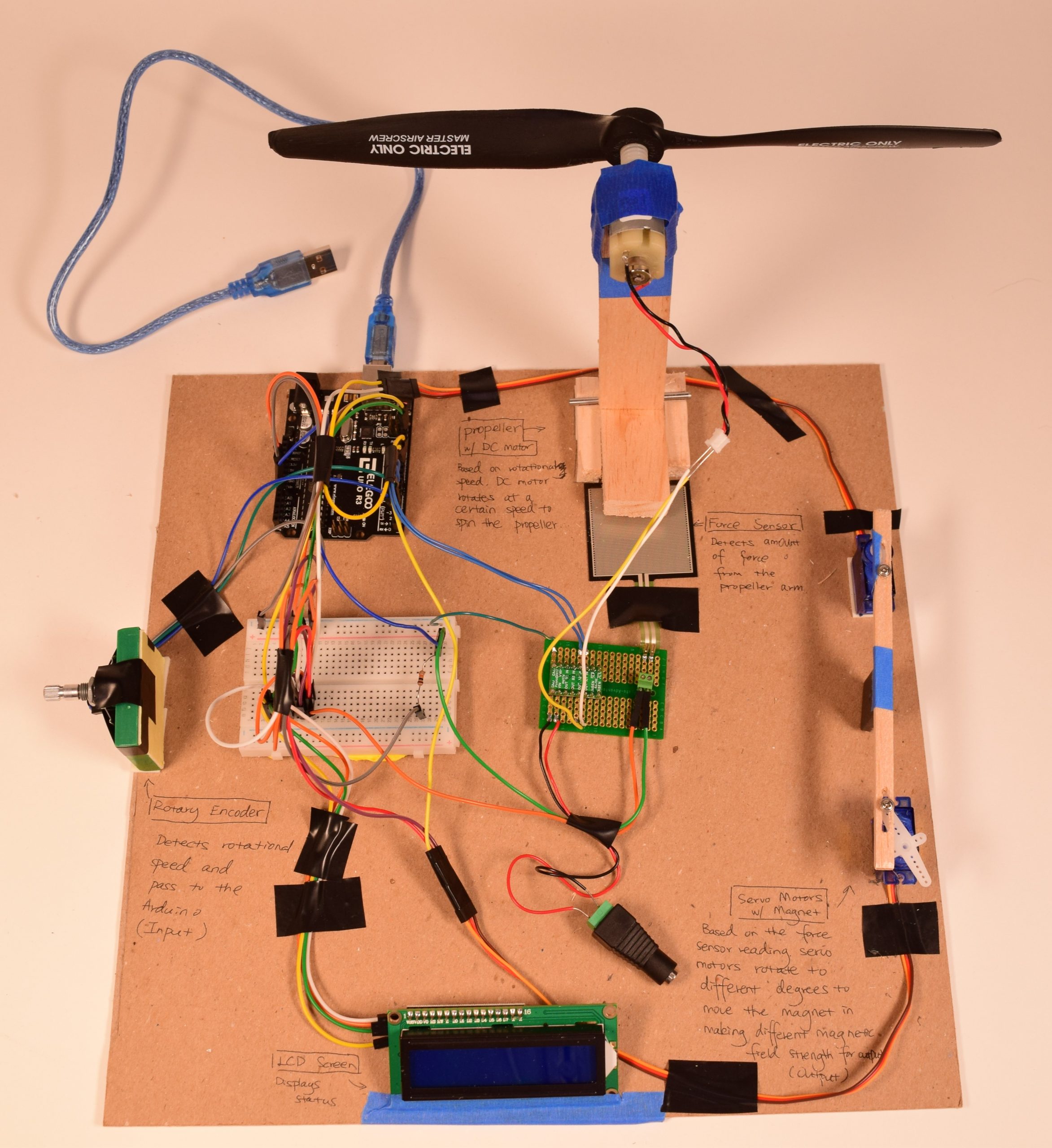

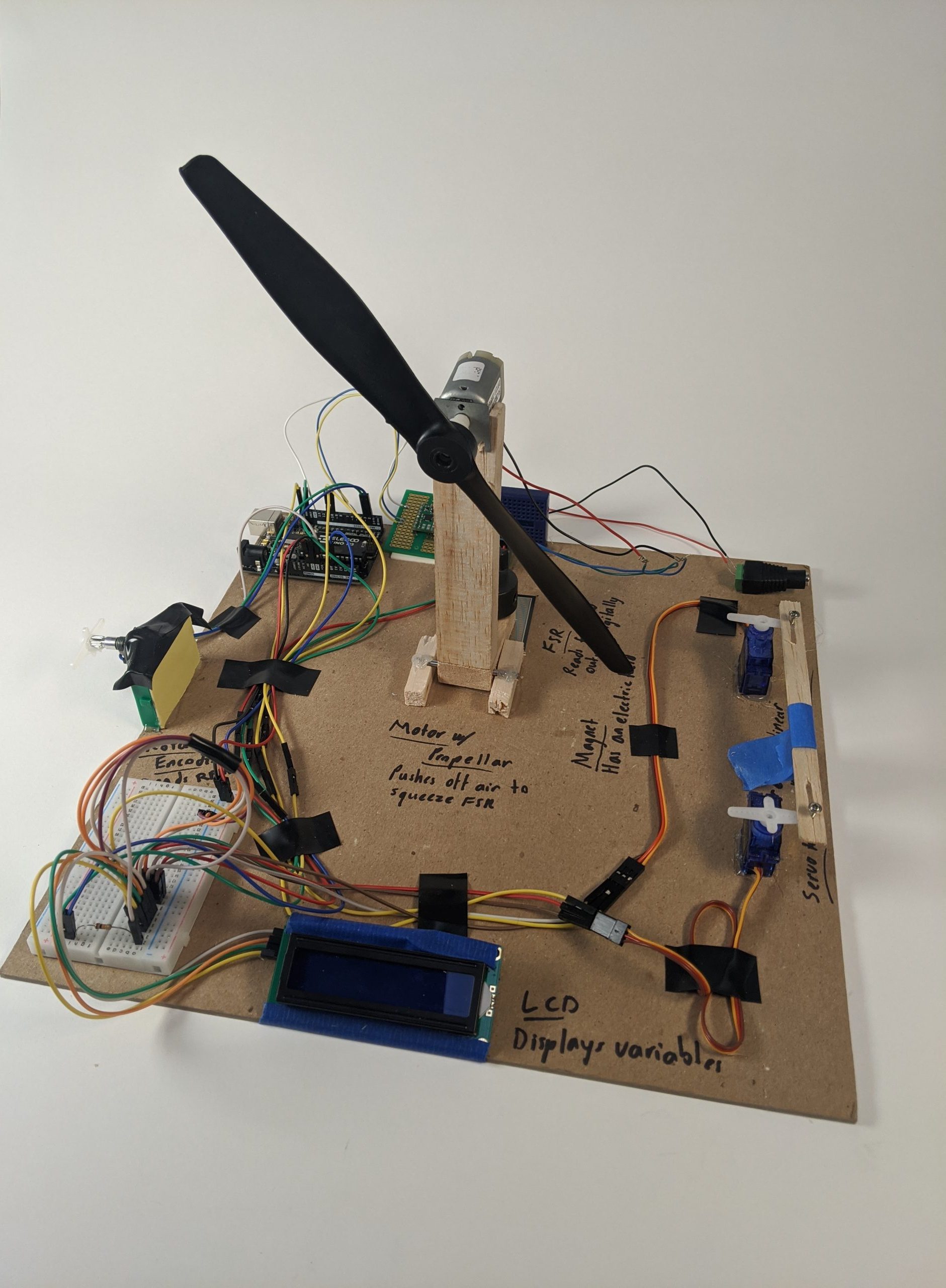

Overall photo

Video of working machine: when rotational speed is at its highest, the propeller spins fast and presses down on the force sensor a lot, which translates to the maximum rotation of servo motors bringing the magnet all the way to the right edge of the board.

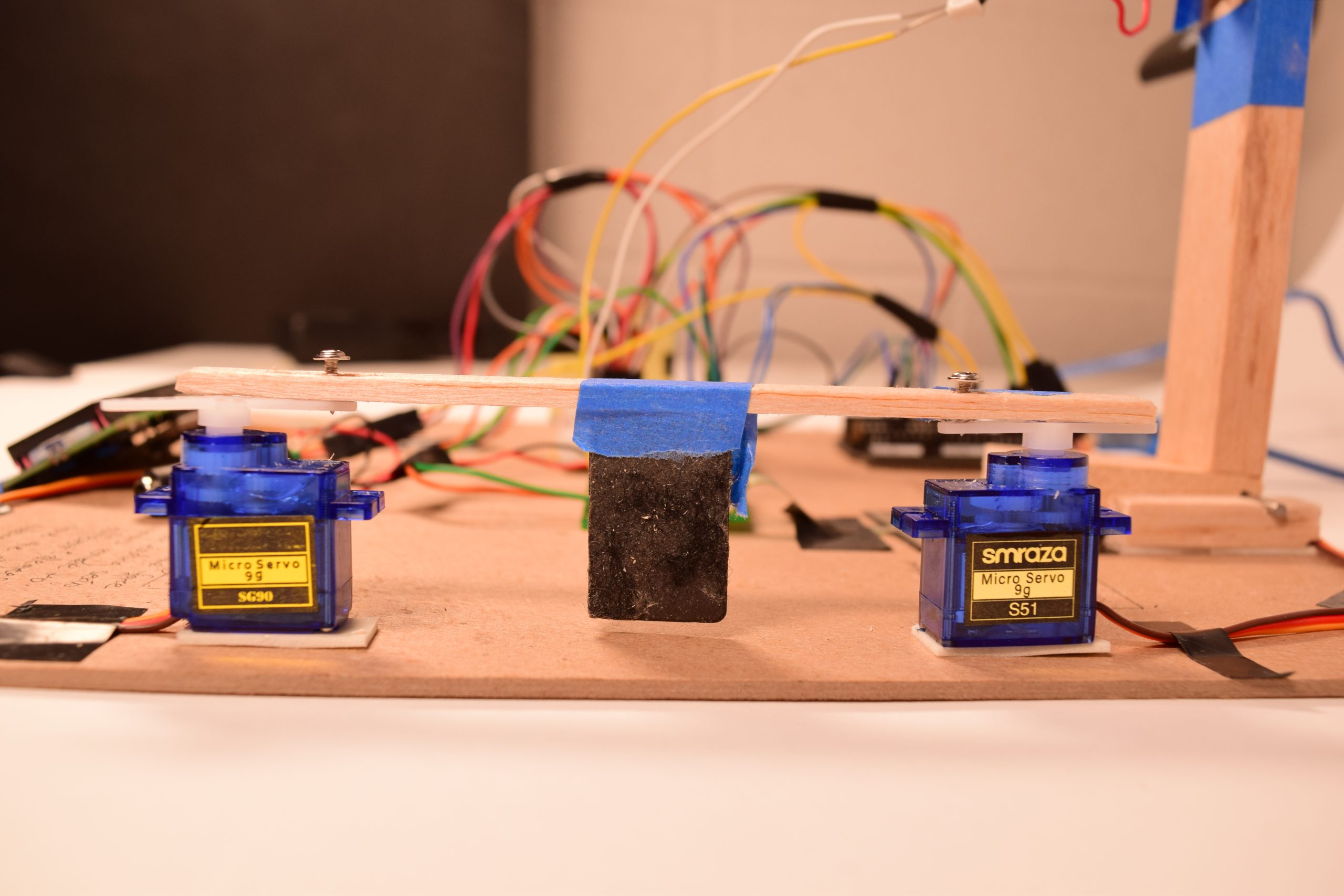

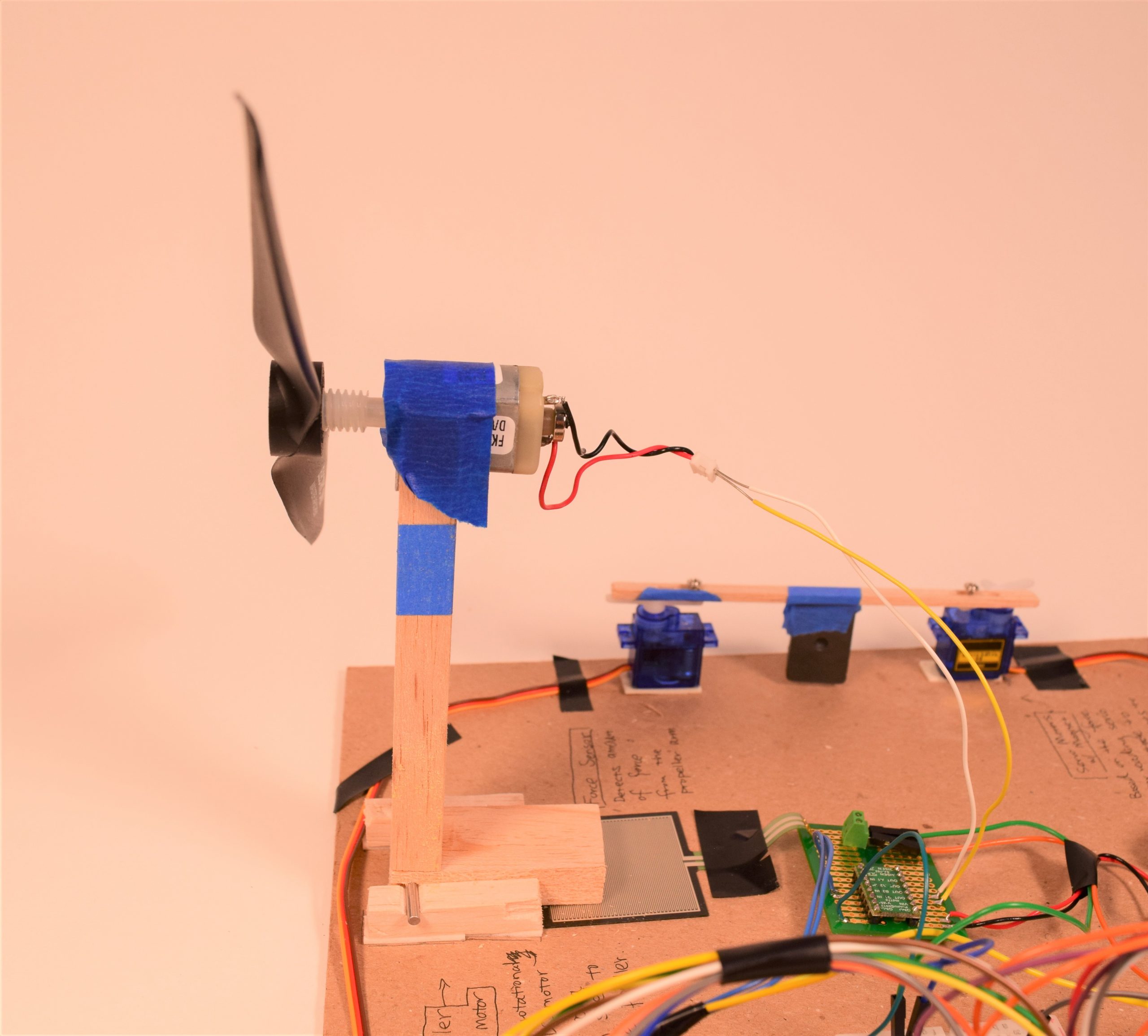

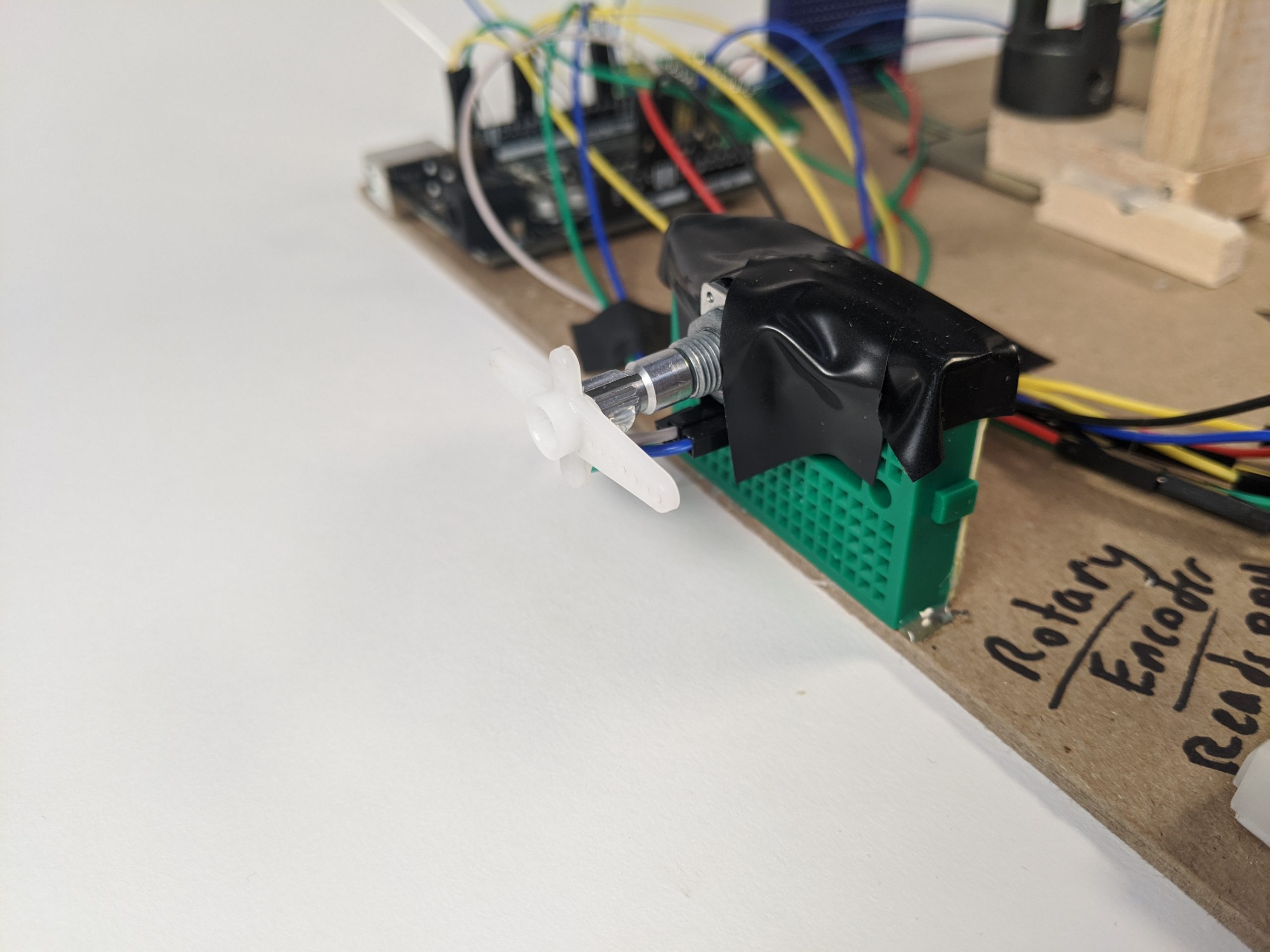

Detail photos of parts

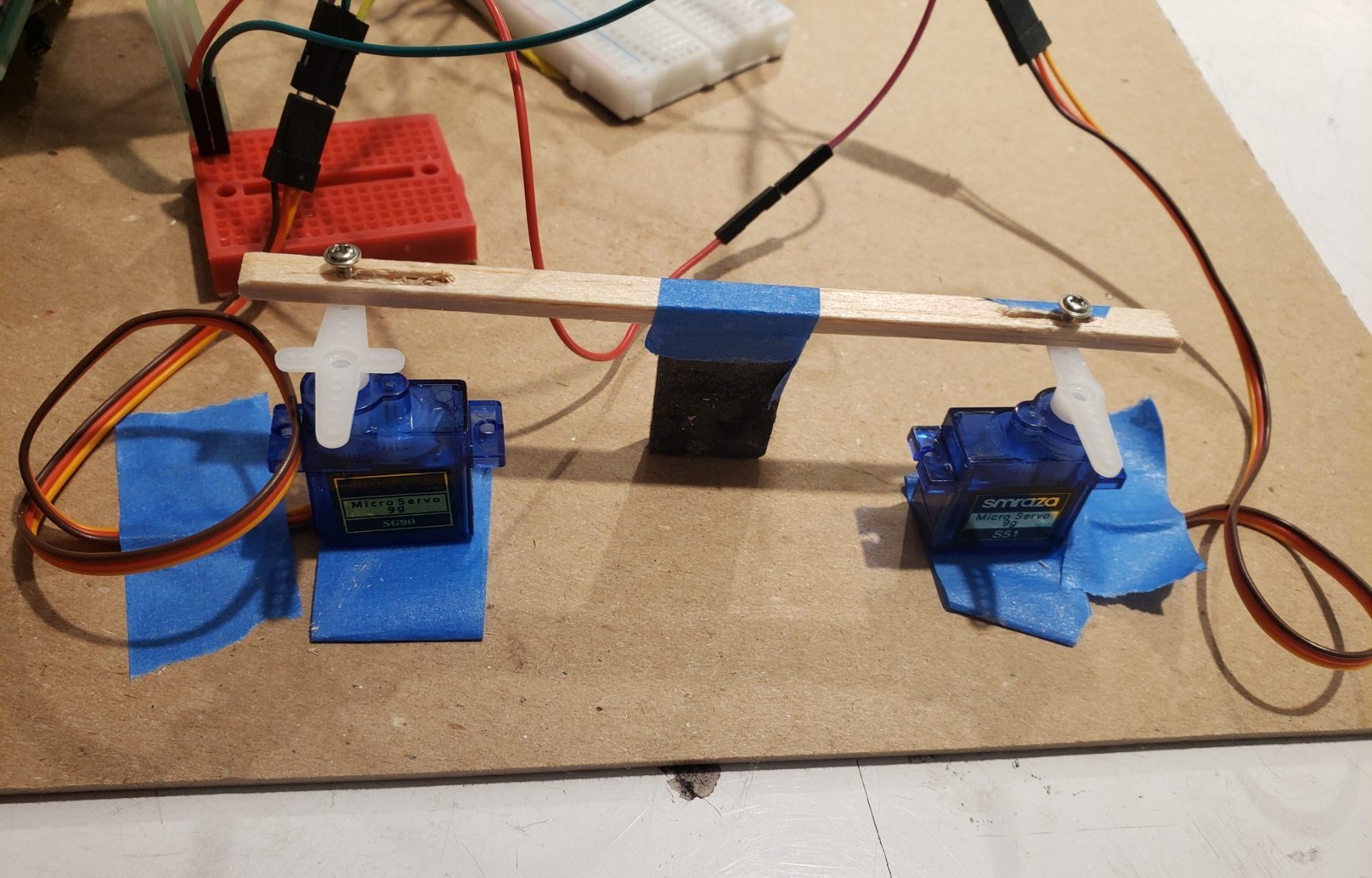

Servo motors holding the magnet (our output)

Propeller connected to a DC motor, standing upright with force sensor at the bottom of the propeller arm (our middle step)

Noel’s Board

Video

The encoder constantly samples rotational speed and determines the voltage passed on to the motor. The greater force translates across the FSR and is translated into servo position. Jittery human input produces similarly jittery magnet position.

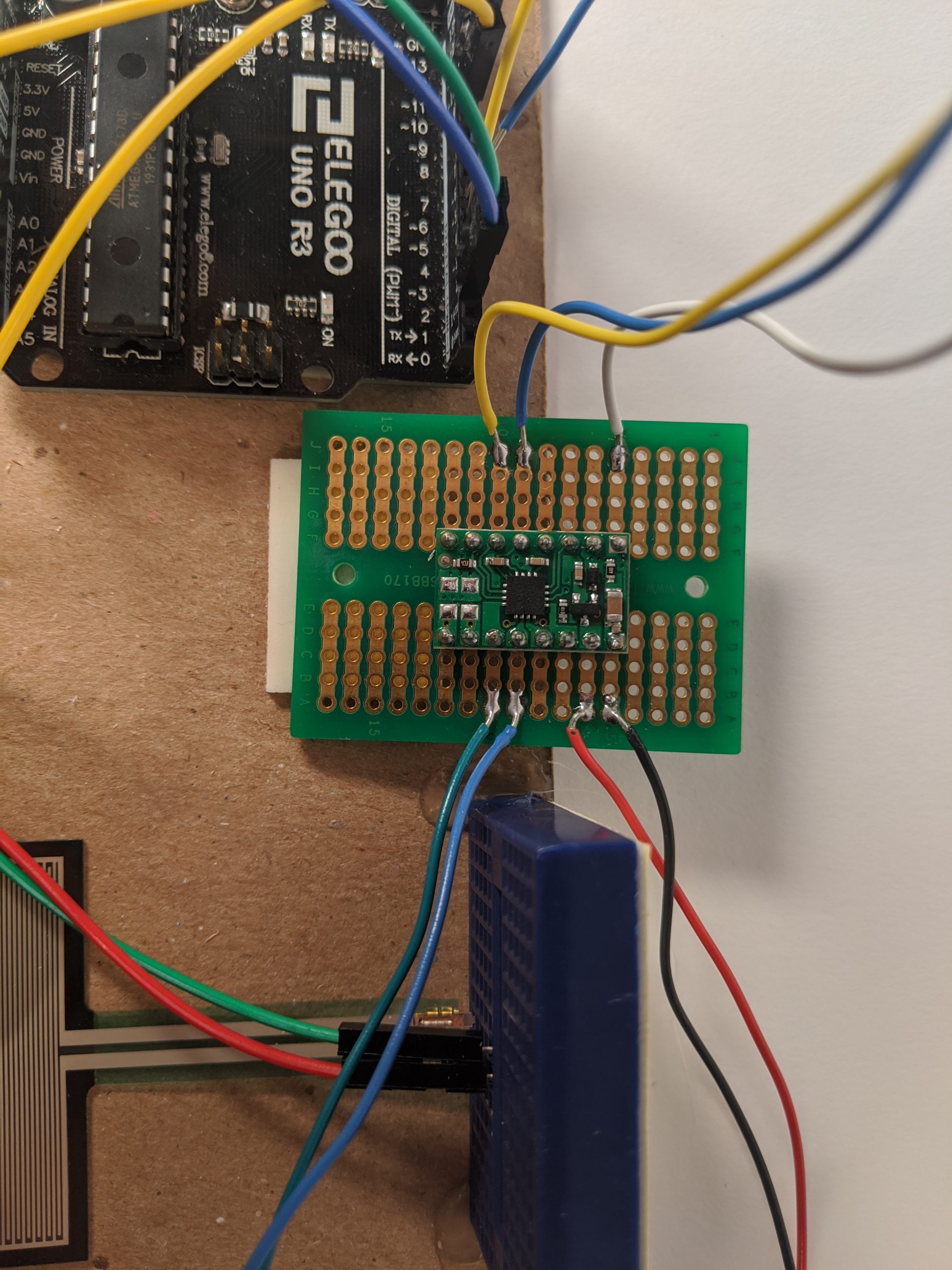

Detail photos of parts

Our solution to the servo-encoder interface between projects, featuring hot glue and luck

The DRV8833, the chip that allows us to drive the DC motor with more than on and off

Narrative Description:

Our input is rotational speed. That is measured by how fast the knob (rotary encoder) gets turned at the left of our boards. This rotational speed is then used to calculate how fast we turn our DC motor, which is connected to a propeller. The propeller sits upright in the middle of our board and it is built in a way so that depending on the spinning speed, the propeller arm tilts in differing amounts to press onto the square force sensor resistor at the bottom. Based on the force reading, degree of rotation for the servo motors are determined. The servos are holding a piece of magnet and greater rotation equals to further distance of the magnet to the next team’s board. With different distances, we create different strengths of magnetic field which is our output.

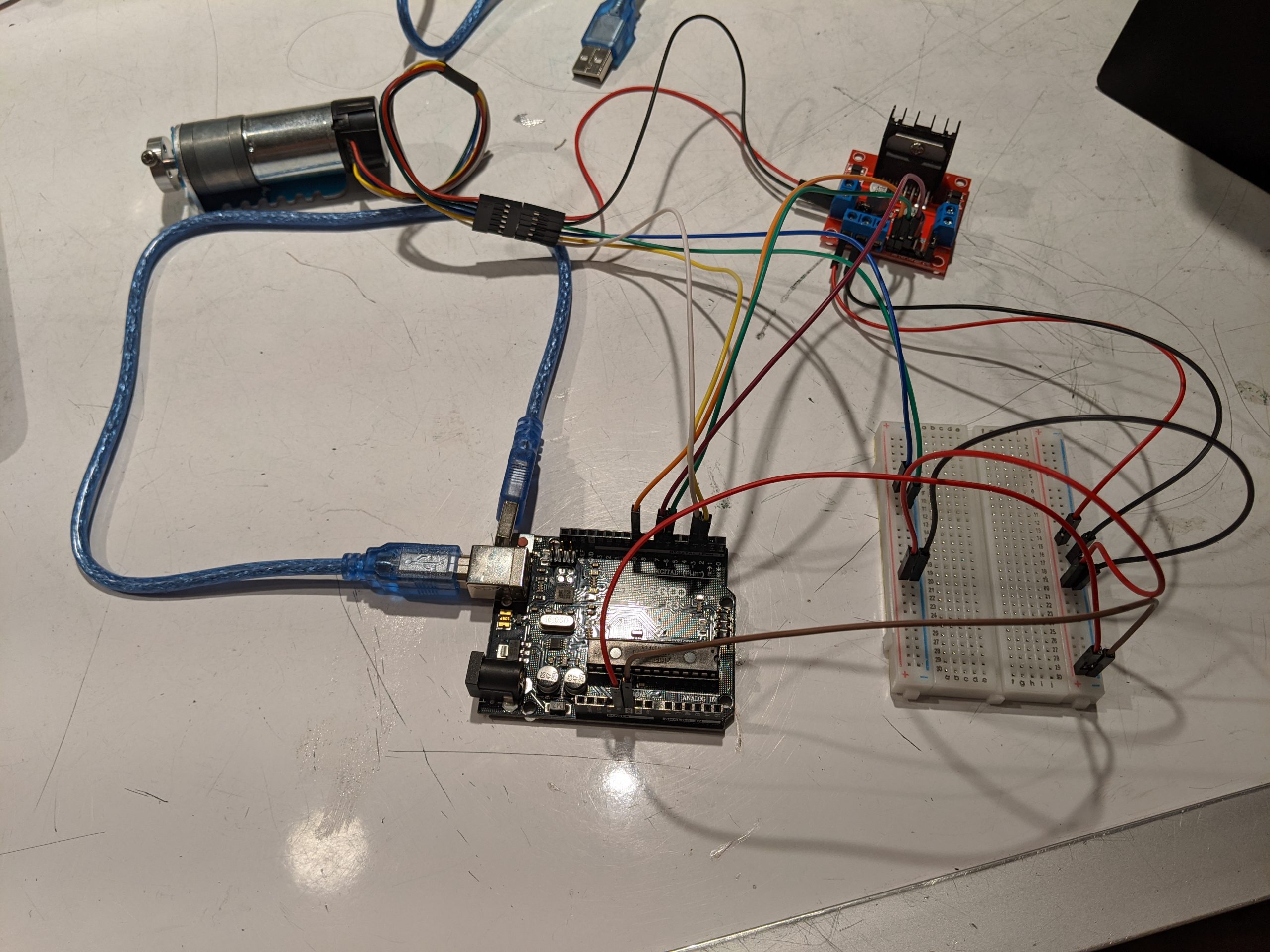

Progress Images:

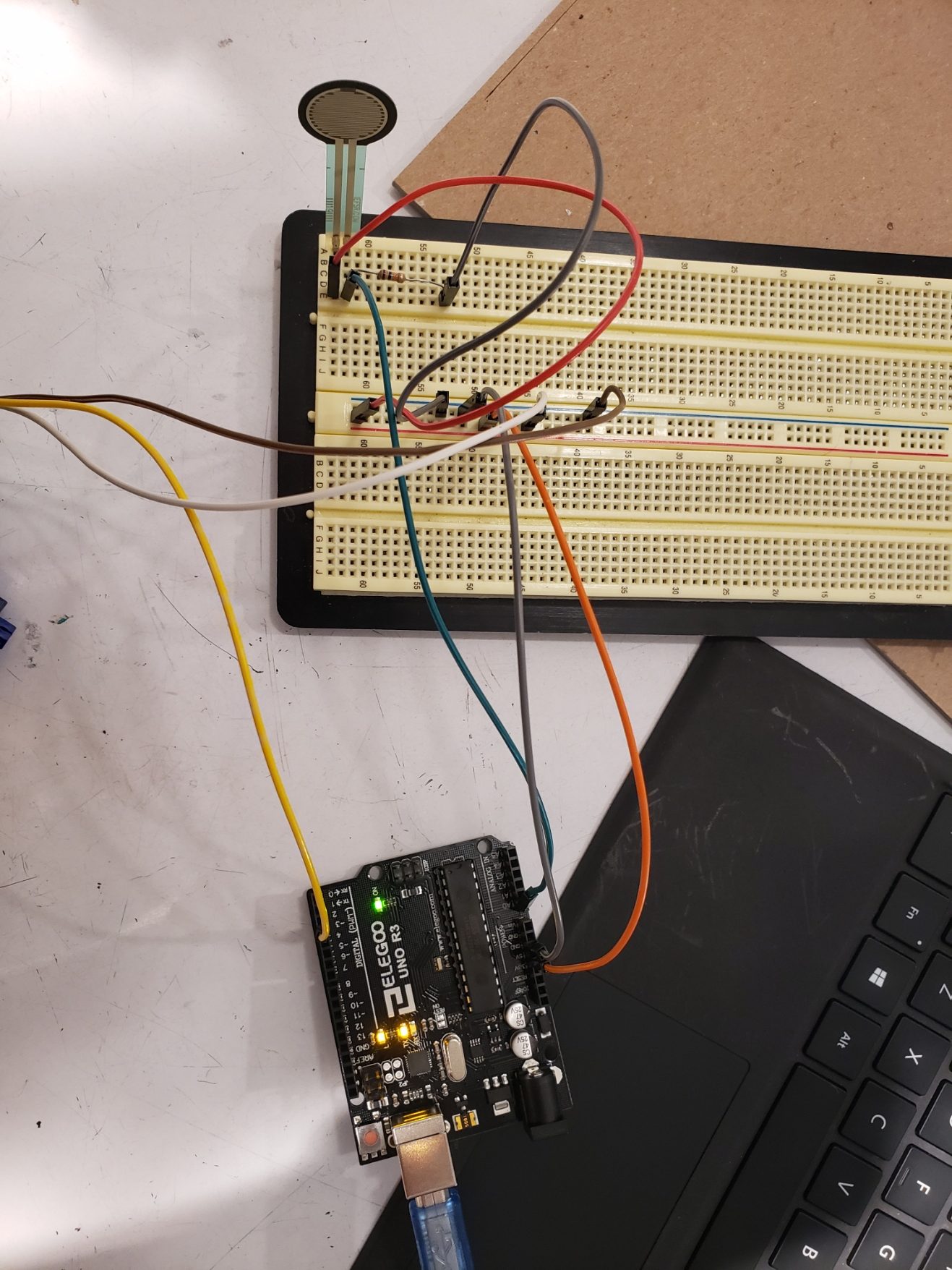

An early mock up of the motor wiring. Using a motor with an encoder and voltage regulator board. Replaced by simple motor and motor driver.

Force Sensor Testing: wiring up the fsr to see how it reads by making it print in Serial Monitor Testing out the positions of servo motors. This was a critical step as we changed from our original design of using rubber bands arms sliding the magnet along a track to using a rigid arm.

Testing out the positions of servo motors. This was a critical step as we changed from our original design of using rubber bands arms sliding the magnet along a track to using a rigid arm.

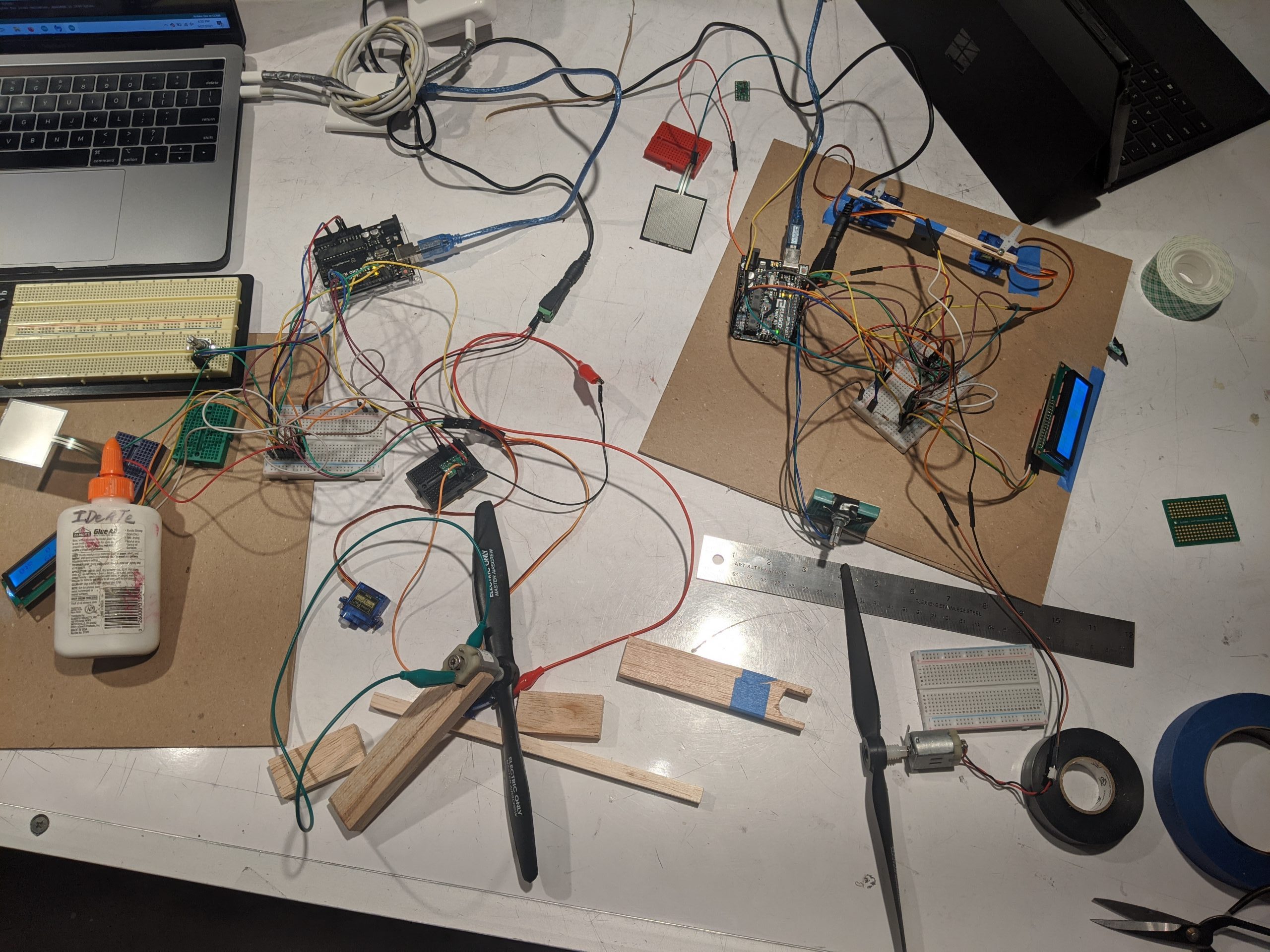

One of the final troubleshooting phases. After re-seating every cable and testing every sensor, an incompatible power supply was the culprit.

Discussion:

The development of this project was a rollercoaster. Initial ambitions were blinding and made issues very easy to overlook, and there were several that we did. We made two simple backups and spent all of our creative power on integrating a windmill. We easily overlooked issues like creating linear motion with servos, balancing and connecting a propeller, and the interface between encoder and previous project’s servo. Our imagined outcome was not adherent to all the real physical limitations, and this would be apparent when we tried to share ideas. Solidworks, hand drawings, and real physical progress ultimately bridged the gap between the imagined and the real.

Through our build we were constantly reminded of the many tools that had already been developed before us. In an attempt to use as powerful a motor as we could find, we showed our lack of intuition for thrust and knowledge of available parts. Thanks to our professor, online resources, and physical testing, we derived something efficient and conceivable. These resources were invaluable, as neither of us had any idea a DRV8833 (dual motor driver carrier) was an available tool. Peers also helped ideation, and the learning environment was a significant help in understanding what we could accomplish. Miniature breadboards and switching to square FSRs were two results of the vibrant learning environment.

One of the most frustrating steps was connecting libraries and pre-existing code with our own. From completely unresponsive to mapped and tuned scaling, the troubleshooting often involved scrapping entire drafts and scouring for relevant sample code. Here it was obvious that we were “standing on the shoulders of giants.” With documentation from the course webpage and from online users with valuable experience with each part, we had plenty of comments to read and build our understanding of how we could connect each sensor and output device. Despite the plethora of technical documentation, we still sometimes found ourselves adjusting parameters through trial and error. In combining available resources and first hand experience, we were able to develop the system we imagined.

Functional Block Diagram:

Schematic:

Code:

/*Project Title: Double Transducer: Rotational Speed -> Magnetic Field Strength

Team Members: Noel Barnes, Yuqi (Alice) Zhou

Description: Arduino takes in input from a rotary encode to calculate the rotational speed.

This speed is then mapped into a speed that's feed into the DC motor to drive a propeller.

FSR then picks up a force reading from the tilt of the Propeller arm.

The force reading is then mapped to a rotation degree for the servo motor.

Servo motors are moved based on the rotation to move the magentic forward.

Pin mapping:

Arduino pin | role | description

------------|--------|-------------

A0 input FSR for force sensing

2 input rotary encoder pin A

3 input rotary encoder pin B

5 input drv8833 A2 IN

6 input drv8833 A1 IN

10 output servo motor #1

11 output servo motor #2

SCL SCL of LCD

SDA SDA of LCD

Rotoray Encoder Code adapted from https://dronebotworkshop.com/rotary-encoders-arduino/#Arduino_Motor_Encoder_Sketch DroneBot Workshop 2019

DC motor code adapted from https://courses.ideate.cmu.edu/16-223/f2016/text/lib/WheelDrive.html#wheeldrive-doxygen

*/

#include <Servo.h>

#include <Wire.h>

#include <LiquidCrystal_I2C.h>

LiquidCrystal_I2C screen(0x27, 16, 2);

// Motor encoder output pulse per rotation (change as required)

#define ENC_COUNT_REV 374

// Encoder output to Arduino Interrupt pin

#define ENC_IN 3

// Pulse count from encoder

volatile long encoderValue = 0;

// interval for measurements of rotational speed

int interval = 100;

const int quaterSec = 250;

unsigned long timer = 0;

long previousMillis = 0;

long currentMillis = 0;

int rpm = 0;

int rpmDisplay; // RPM display for the LCD screen

int motorRPM; // DC motor speed

int dcDisplay; // DC motor speed display for LCD screen

//make a servo object

Servo lilMotor;

Servo secMotor;

const int LILMOTORPIN = 11; // Servo Motor to pin 11

const int SECMOTORPIN = 10; // Servo Motor to pin 10

int force; // the analog reading from the FSR

int forceDisplay; // force display for the LDC screen

int fsrPin = 0; // the FSR and 10K pulldown are connected to a0

int rotation; // rotation degree for lilMotor

int rotationTwo; // rotation degree for secMotor

int rotationDisplay; // servo motor rotation display for LDC screen

#define A1PIN 6

#define A2PIN 5

void setup() {

// Set encoder as input with internal pullup

pinMode(ENC_IN, INPUT_PULLUP);

// Attach interrupt

attachInterrupt(digitalPinToInterrupt(ENC_IN), updateEncoder, RISING);

// Setup initial values for timer

previousMillis = millis();

// initialize DC motor

pinMode(A1PIN, OUTPUT);

pinMode(A2PIN, OUTPUT);

digitalWrite(A1PIN, LOW);

digitalWrite(A2PIN, LOW);

// tell Arduino where the servo motors are plugged in

lilMotor.attach(LILMOTORPIN);

secMotor.attach(SECMOTORPIN);

// initialize the screen (only need to do this once)

screen.init();

// turn on the backlight to start

screen.backlight();

// lcd display template

screen.home();

screen.print("i:");

screen.setCursor(6, 0);

screen.print("m:");

screen.setCursor(12, 1);

screen.print("o:");

}

void loop() {

// Update RPM value

currentMillis = millis();

if (currentMillis - previousMillis > interval) {

previousMillis = currentMillis;

// Calculate RPM

rpm = (float)(encoderValue * 60 / ENC_COUNT_REV);

//follow the range of 20-60 for rotational speed

if (rpm > 60) {

rpm = 60;

}

if (rpm < 20) {

rpm = 20;

}

encoderValue = 0;

}

//rotational speed display

if (millis() - timer >= quaterSec) {

screen.setCursor(2, 0);

rpmDisplay = map(rpm, 20, 60, 0, 99);

screen.print(rpmDisplay);

}

// run DC motor with RPM

motorRPM = map(rpm, 20 , 60, 80, 255); //normalize rotational speed to input as DC motor speed

digitalWrite(A1PIN, LOW);

analogWrite(A2PIN, motorRPM);

delay(2);

// DC motor speed display

if (millis() - timer >= quaterSec) {

screen.setCursor(8, 0);

dcDisplay = map(motorRPM, 80, 255, 0, 99); // normalized for display

screen.print(dcDisplay);

}

// force reading

force = analogRead(fsrPin);

// limit to a force range that's appropriate for the propeller arm setup

if (force > 400) {

force = 400;

}

if (force < 50) {

force = 50;

}

// force sensor display

if (millis() - timer >= quaterSec) {

forceDisplay = map(force, 50, 400, 0, 99); // normalized force for display

screen.setCursor(8, 1);

screen.print(forceDisplay);

}

// calculate rotation for the two servo motors

rotation = map(force, 50, 400, 10, 170); // map force reading to motor rotation degree

rotationTwo = 180 - rotation;

// servo motor rotation degree display

if (millis() - timer >= quaterSec) {

rotationDisplay = map(rotation, 10, 170, 0, 99); // normalized rotation degree for display

screen.setCursor(14, 1);

screen.print(rotationDisplay);

timer = millis();

}

// rotate the servo motors

lilMotor.write(rotation);

secMotor.write(rotationTwo);

}

void updateEncoder()

{

// Increment value for each pulse from encoder

encoderValue++;

}