Project Objectives:

grubo is a set of soft pneumatic actuators compatible with the Lego Technic system. The kit consists of expandable silicone air chambers, Lego-compatible connector pieces, and tubing and syringes to inflate the air chambers. Using the grubo pieces, builders can expand the functionality of their Lego creations with soft pneumatic actuation.

Creative Design Opportunities:

We imagine that the findings from our project can be implemented in various contexts, they are:

Within an educational institution: We imagine this set to be useful in providing a low barrier of entry for students in elementary schools to introduce students to pneumatic actuation through a method of creative play with which they are already familiar. Students may be given kits with Lego and grubo components, as well as instructions to guide students through projects that take advantage of the pneumatic actuation. This could also be implemented within other educational facilities like children’s museums, where interaction and collaborative play is encouraged.

A Lego Technic Set Add-on: A second potential avenue is to productize the kit. This concept is similar to existing Lego expansion kits that can add, for example, motorized functionality to already existing kits as well as new creations. In addition to being included in add-on kits, grubo components could also be incorporated into novel Lego sets, using the soft actuators to meet a specific designed end. We imagine this could interest established Lego fans.

grubo in Sculpture: The movement of the silicone components could also be used for biomimetic, sculptural ends . We named this project, somewhat facetiously, as grubo: a portmanteau of the words “grub” and “Lego,” because of the parts’ movement evoking images of larvae. Artists could employ these more complex versions of these connectors in artistic works to create dynamic, lifelike movements.

Outcomes:

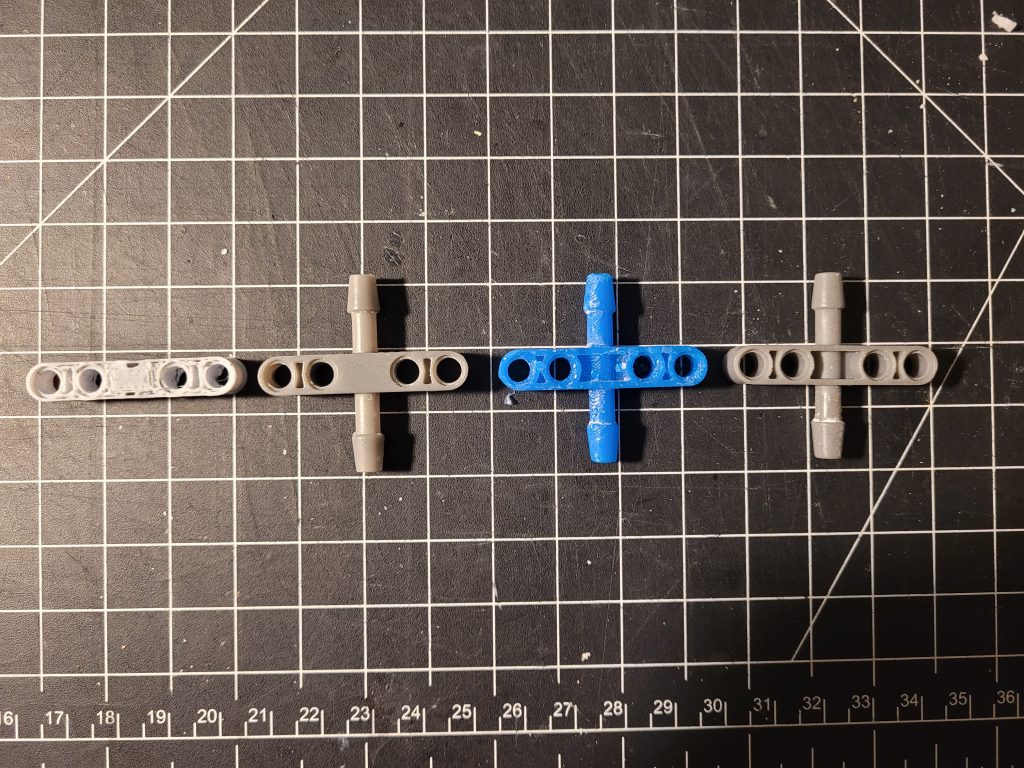

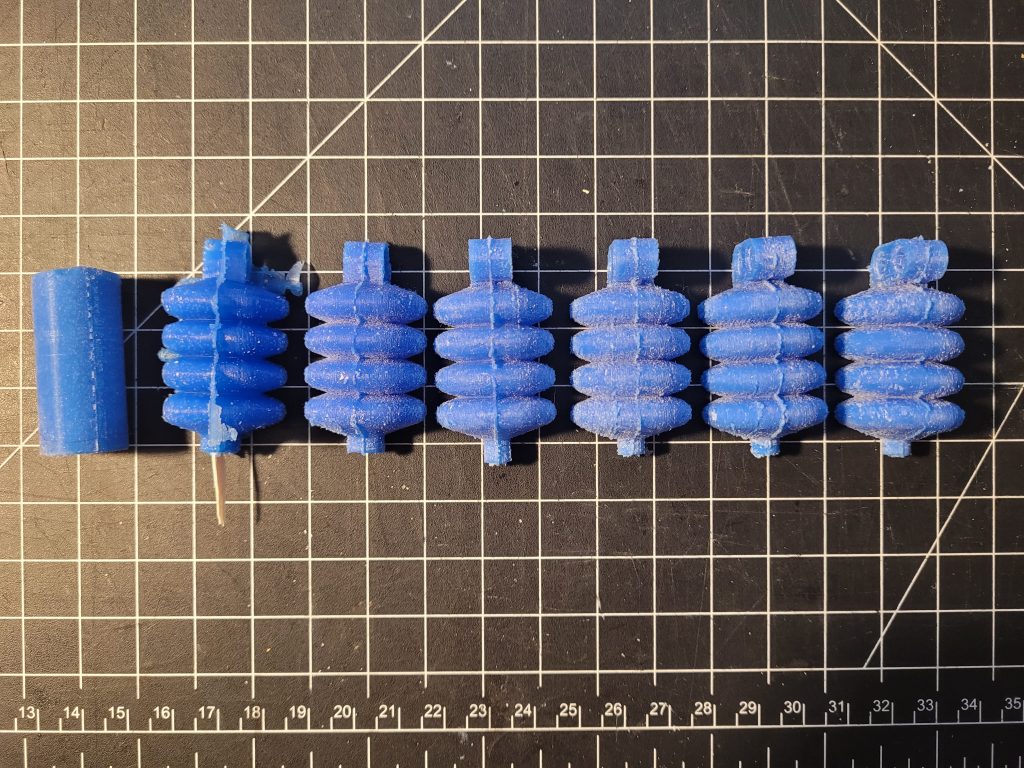

Over the course of this project we developed a proof of concept for a kit of soft, inflatable, Lego-compatible components. While we only produced one one type of inflatable (one that bends when inflated) and one type of Lego connector (a 5-unit long male-male connector), we created parts that lay a clear groundwork for a whole line of similar pieces. The novel components also add new functionality to a Lego kit of parts, adding flexible, pneumatic actuation Technic-style builds.

We also developed a method for producing silicone inflatables with geometrically complex inner cavities. By making paraffin wax internal negatives and then melting them out of the cured silicone parts, we were able to produce monolithic silicone parts with internal cavities too large to remove rigid negatives from.

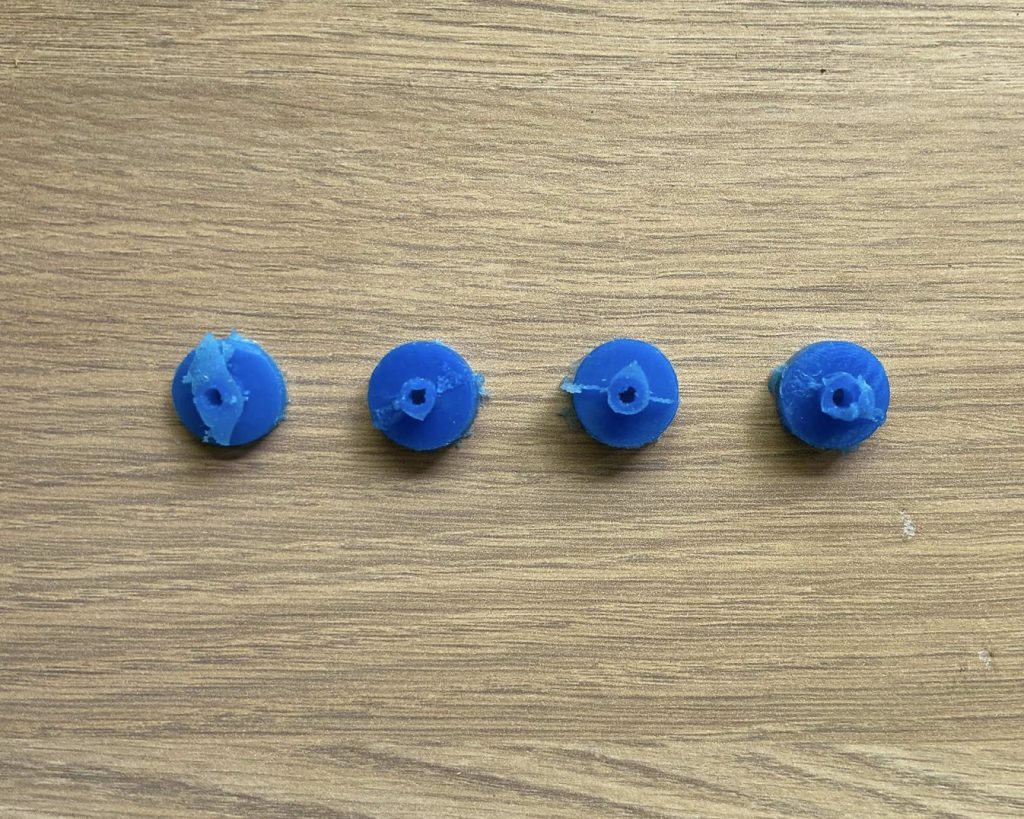

While we regard this project as an overall success, we have left notable room for improvement. By using a single, round connection point, the silicone parts can rotate around the air nozzles without much user control. Given the non-rotationally-symmetric nature of the silicone parts, this results in Lego builds that could be challenging to keep in a consistent state. Furthermore, the bistable connector nozzle is significantly narrower than the mouth of the plastic nozzles, a design choice that increases stability of the connection, but makes it challenging to easily mount the silicone pieces onto the plastic nozzles. This would likely prove a particular challenge for children, a target demographic of these toys. Additionally, we put not thought into how the syringes interact with the Lego system, so the syringes feel very unintegrated into the wider kit. Lastly, given the narrow range of parts we developed, the system lacks flexibility. Future iterations of this project would benefit from prioritizing solutions to these issues.

Citations:

While we looked at a lot of resources developing this project, we took primary inspiration from the following three:

- Chao Zhang, Pingan Zhu, Yangqiao Lin, Zhongdong Jiao, Jun Zou. “Modular Soft Robotics: Modular Units, Connection Mechanisms, and Applications.” Advanced Intelligent Systems, Volume 2, Issue 6, page 1900166. 2020. doi: 10.1002/aisy.201900166.

This paper presents a number of methods for creating modular soft robots. We found the high-level design specifications of our bistable connector from this paper. - Jun-Young Lee, Jaemin Eom, Woo-Young Choi, Kyu-Jin Cho. “Soft LEGO: Bottom-Up Design Platform for Soft Robotics.” 2018 IEEE/RSJ International Conference on Intelligent Robotics and Systems, Madrid, Spain, pages 7513-7520. 2018. doi: 10.1109/IROS.2018.8593546.

A primary conceptual inspiration for our project. This paper presents another Lego-compatible inflatable soft actuator. These parts are compatible with the bricks rather than the Technic elements, and we through there was room to do more with the concept than was being done in this paper. - Golan Levin, Shawn Sims. Free Universal Construction Toy. 2012. url: http://fffff.at/free-universal-construction-kit/.

The Free Universal Construction kit was another conceptual inspiration for our project. Similar to the previous citation, this work presents a kit of parts that can expand the functionality of the Lego (and other branded) building systems. - X. Lu, W. Xu, X. Li. “A Soft Robotic Tongue–Mechatronic Design and Surface Reconstruction.” IEEE/ASME Transactions on Mechatronics, Volume 22, Issue 5, Pages 2102-2110. October 2017. doi: 10.1109/TMECH.2017.2748606.

The Soft Robotic Tongue provided a primary inspiration for the inflatable component we produced. This paper presents inflatable actuators as part of the tongue that, when inflated, provide a bending motion along one plane. While the actuators in the cited paper are more complex than what we produced, the basic design was adapted for the purposes of our project.

Technical Documentation:

A folder containing zips of our CAD files can be found here.

Contributions:

Sebastian: I focused primarily on developing the inflatable components. I designed the 3D-printed molds. I also figured out how to make the meltable wax internal components, and poured most of the casts.

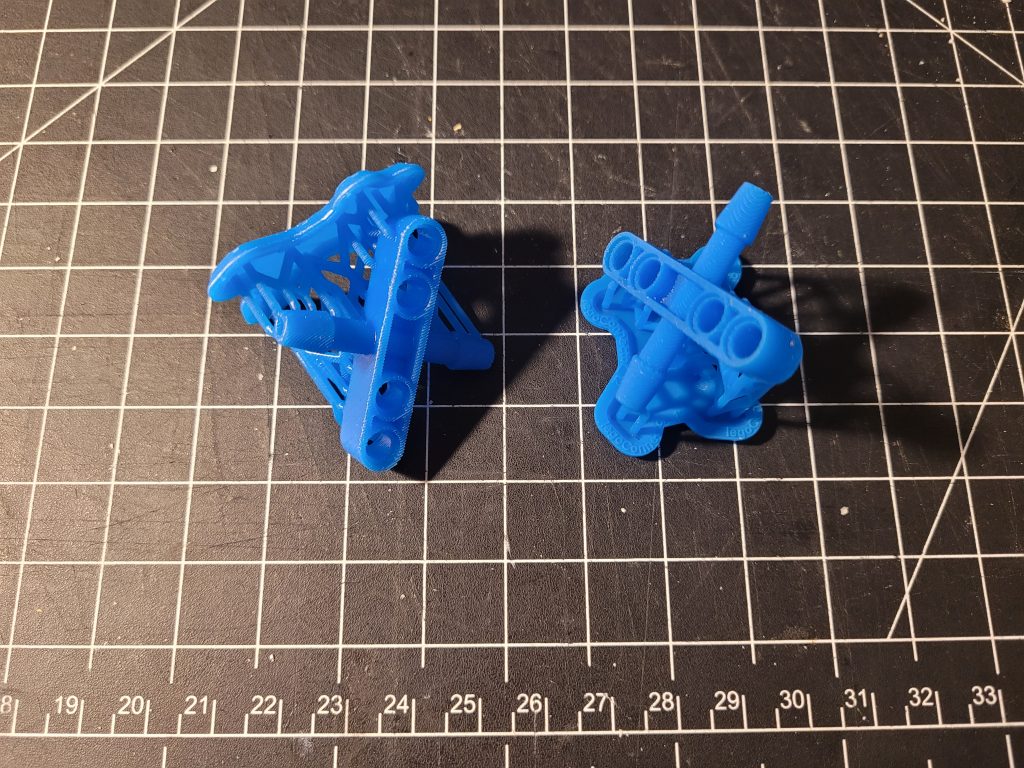

Elena: I designed the hard plastic piece, focusing on the rigid bistable nozzles and adjusting tolerances for Lego compatibility. I also experimented with the bistable connection necks to find the diameters that worked the best.

Together: Both of us worked together to develop the concept for the project and to carry out early balloon and silicone experiments. Towards the end, we both worked together to make edits/fill in gaps left by the other with regards to part manufacturing and documentation.