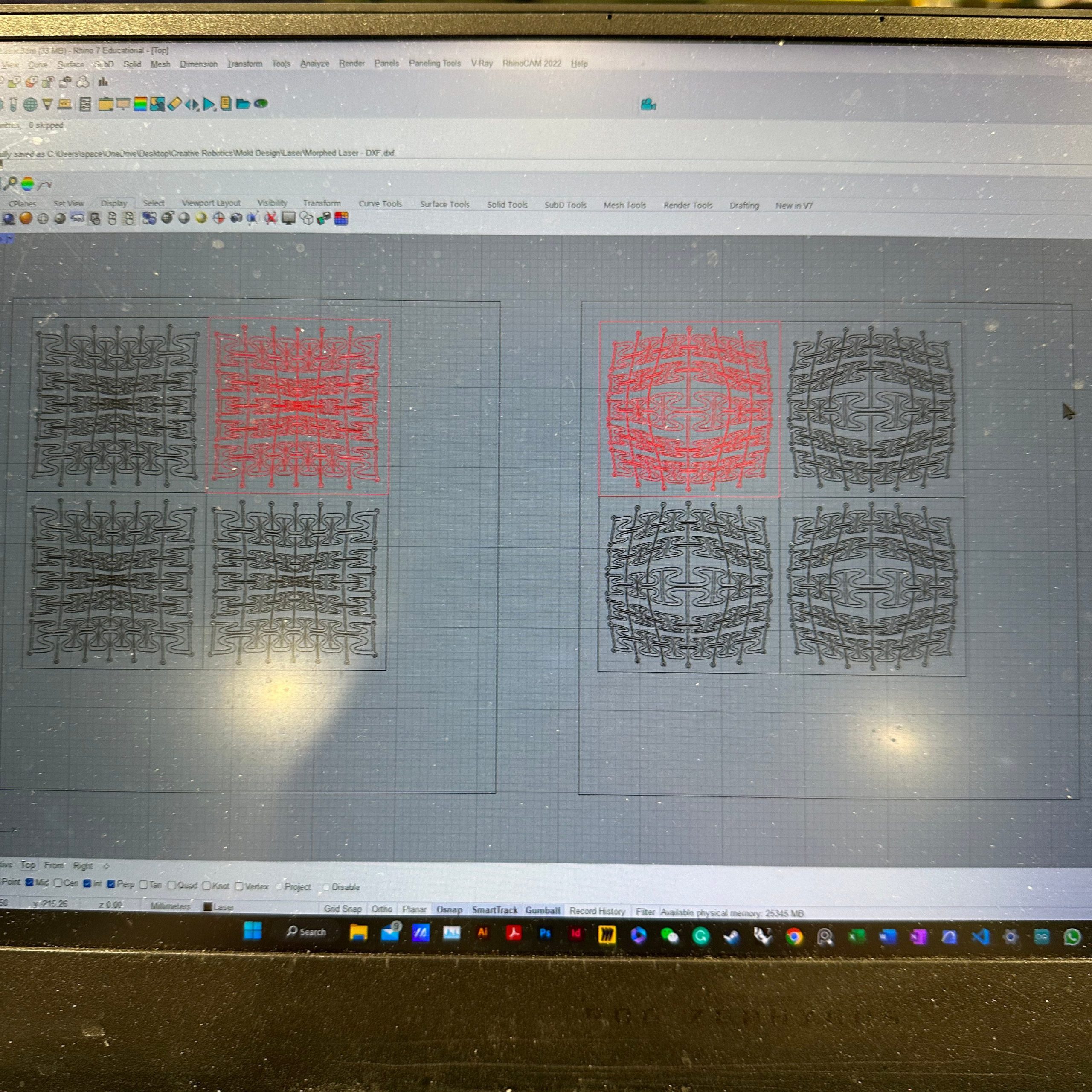

After 6 weeks of mesh experimentation and development, this past week has been focused on final assembly and casting. We decided on 4 main shapes to try: 2 distorted, 1 combined, and one uniform. This allows for a variety of behaviors for our materials and a visually distinct experience for the users.

We were able to 3d print all of our final molds, including the expanded and contracted meshes with fine detail. These will be cast by 4/19, and ready to go for the final assembly.

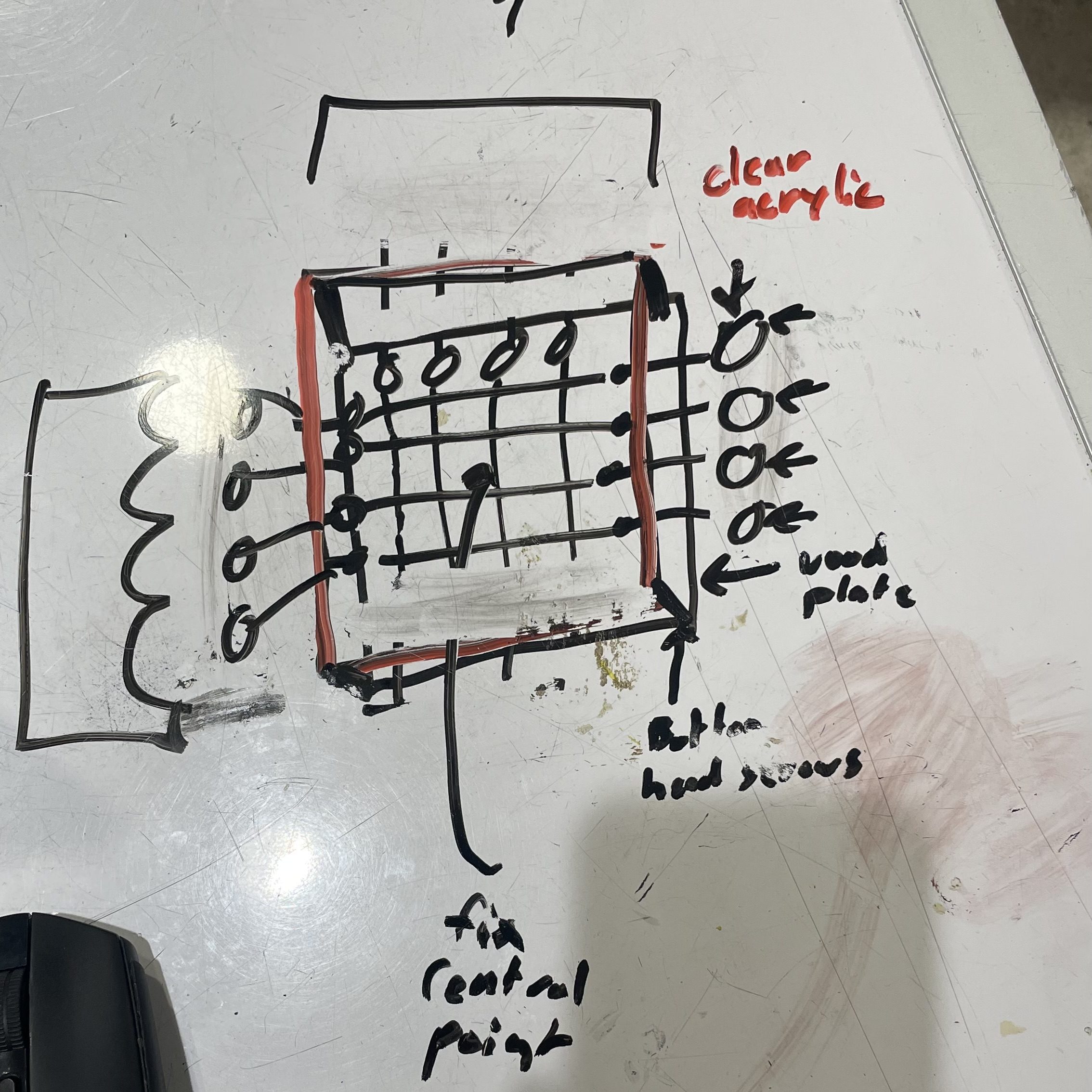

We also finished our system design. Instead of computer control, we decided that direct interaction through a series of handles or rings would provide a more engaging experience for the users. The softness and springiness is intrinsic to our designs, so allowing people to get hands on with it makes more sense. The ability to also distort the meshes at different angles and forces is an advantage of the direct handling. The meshes will then be placed in clear acrylic frames, which will then be connected to the table.

For our final presentation, our conversation with Professor Zeglin was extremely helpful in redesigning the system. We tend to thing very utilitarian with our projects, so having a discussion about presentation and style was very helpful. Our idea is to raise the frames and experiment with lighting over the weekend.

Frame fabrication will take place later this week. We want to leave enough time to test the size, shapes, and interactivity of our system to ensure we make the most use of the interesting properties of the auxetic materials.