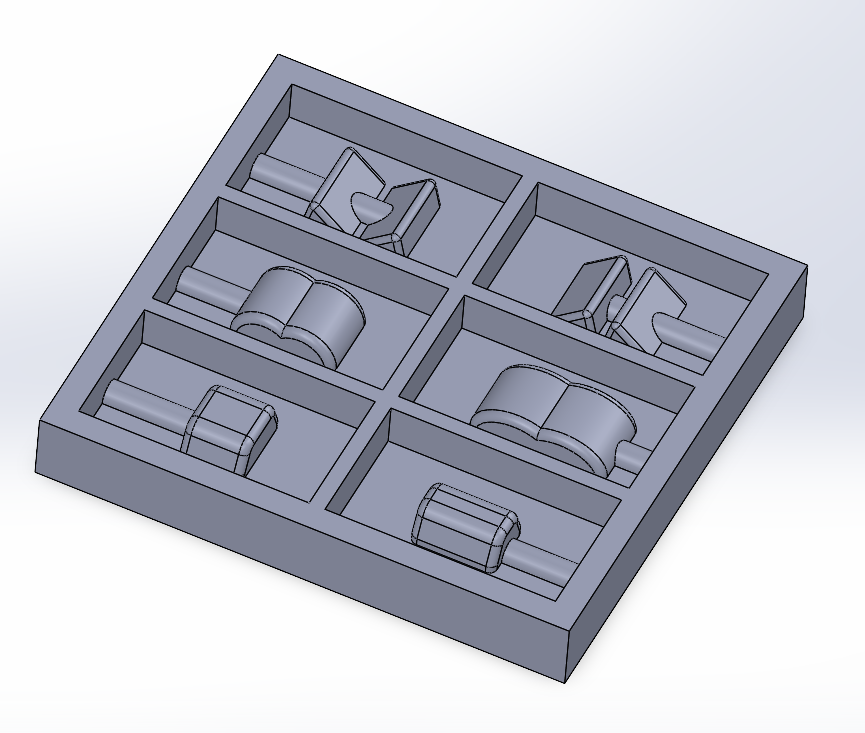

This week we were able to 3D print, cast, and bond 6 miniature test pieces that we had been working on as a means of improving our current finger mold. We created 6 new cavity designs and were able to print molds for them in one go in order to maximize time; we plan on spending today (4/19) testing each part and aim to have a cavity design selected for use in our final iteration by EOD.

Once this decision has been made, we’ll update our existing CAD to both reflect the new cavity shape (if applicable) as well as the thicker bottom of the part that we discussed in previous updates. These modifications should be fairly quick to implement and send to the 3D printer as the current CAD is modularly designed!

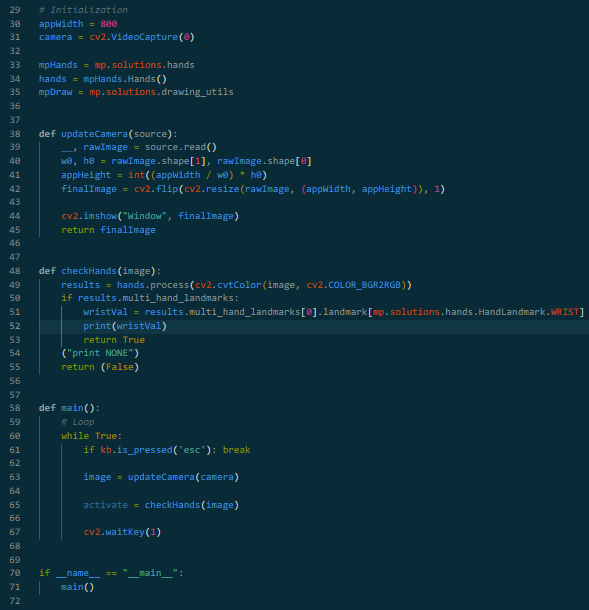

We’ve also begun working on code for the showcase display of our design. The concept behind our display is that a computer vision program would see the user’s hand, decide whether it was open or closed, and activate the pump accordingly such that our model would mirror the position of the user’s hand.

The computer vision portion of the code is completed:

We are currently working on connecting the pumps to be controlled by a raspberry pi pico. The last step will be connecting the two portions of code together!

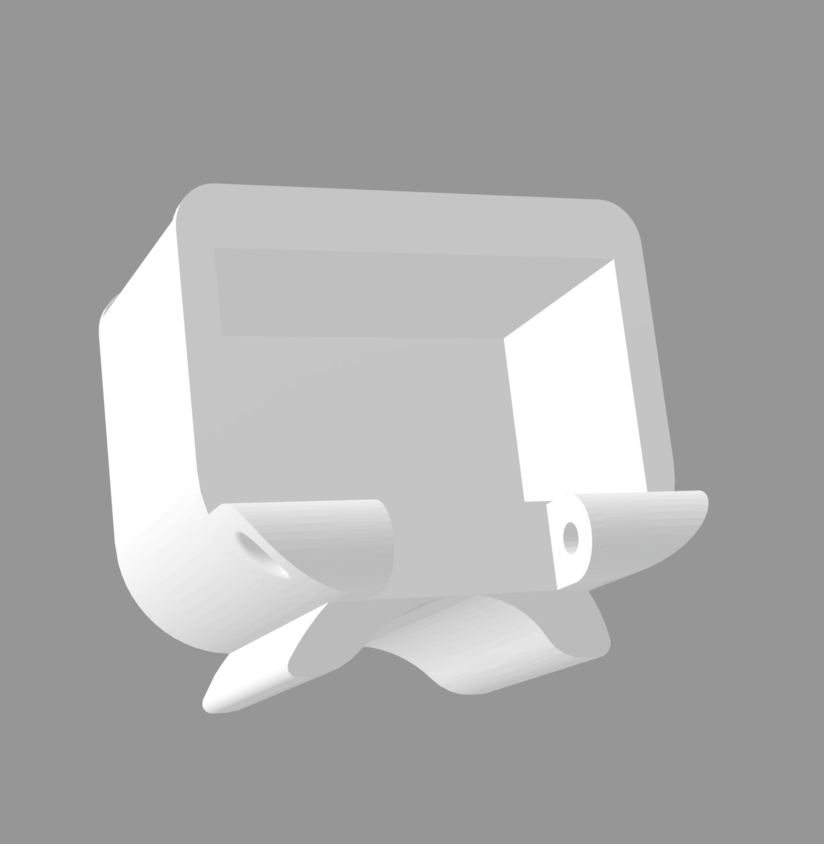

This is the new hinge model, which we expect to be printed in ABS and can be attached to the finger by means of a strap.