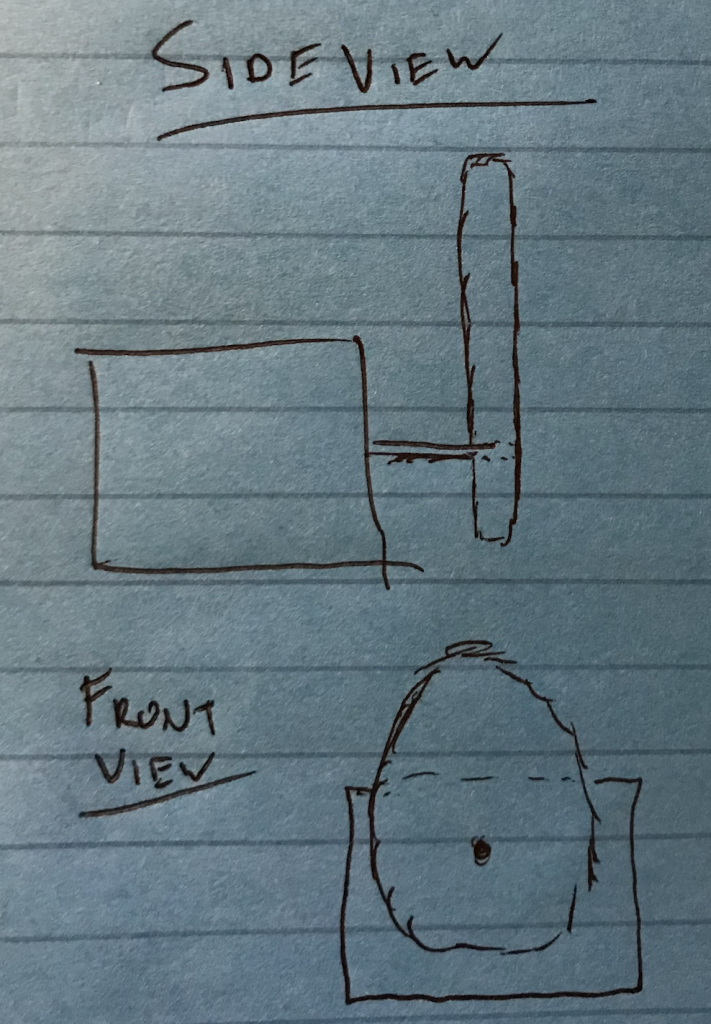

For our first proof of concept demonstration we will be working with one panel, since each panel has the same components and will be easy to replicate. We still haven’t finalized how we plan to raise the panel when it is loaded, but from this proof of concept we are hoping to get more clarity in terms of if we should buy an actual linear actuator, or create one with 3-D printed parts. Our current plan involves a stepper motor attached to a 3-D printed camshaft with a single cam. The cam will rotate to the side or upwards, depending on the pressure sensor’s reading. The sketch below shows the cam in the activated position:

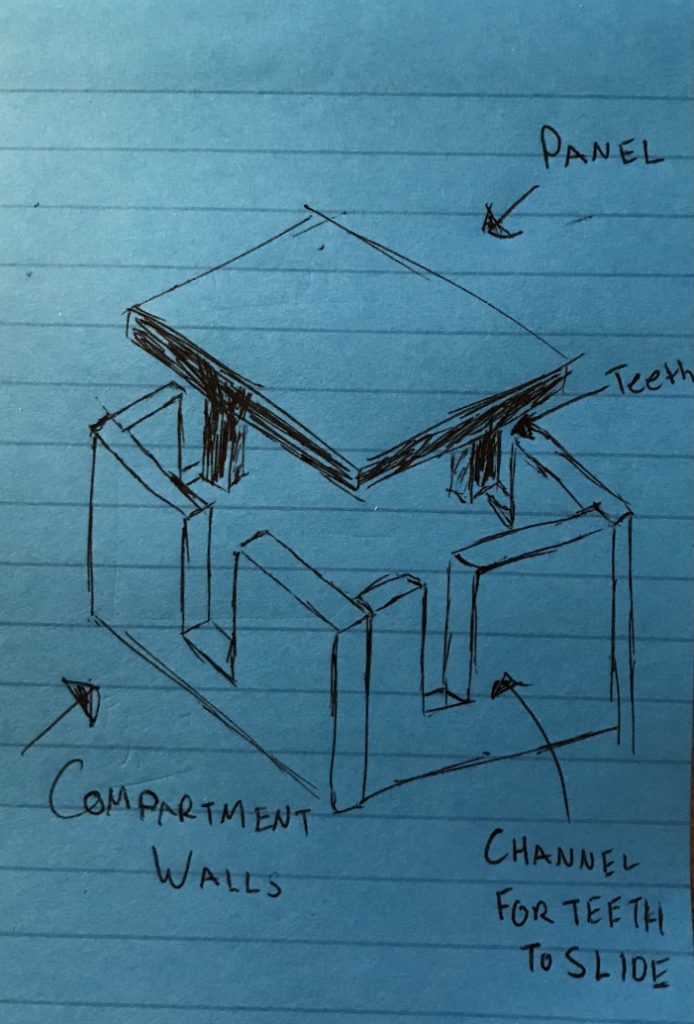

Additionally, we will be experimenting with ways to isolate movement of the panel to one-axis. Our current plan involves “teeth” connected to the bottom of the panel that will slide in a channel in the compartment wall. This may cause unwanted shading of the LED light, so we will find the best possible solution that has minimal effect on the lighting. The current plan is sketched below:

We are both working from Pittsburgh, so we will be able to collaborate through each step of the process. Additionally we both have access to the labs, so we can work together to create files for 3-D printing and laser cutting.

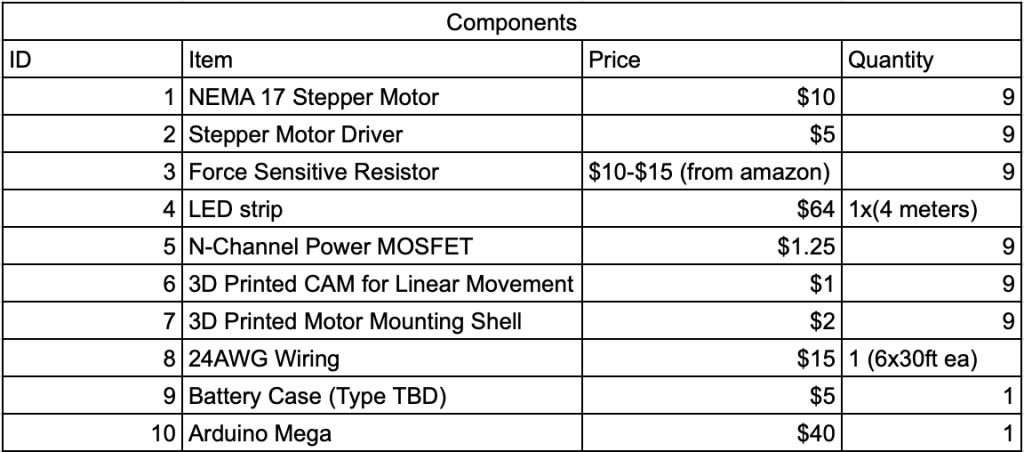

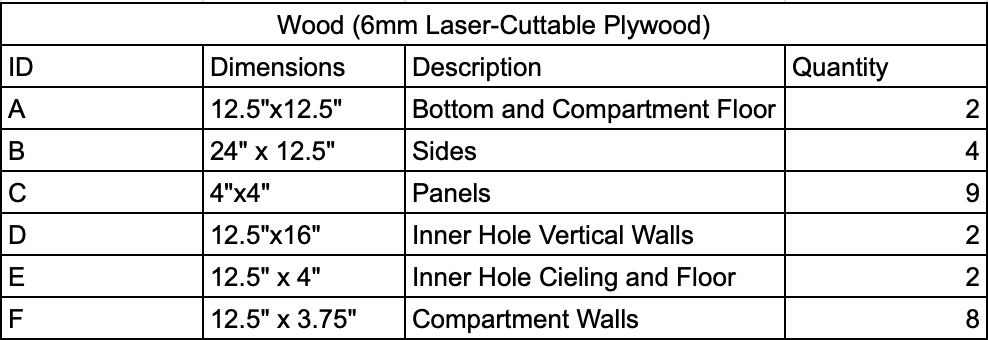

Bill of Materials

Leave a Reply

You must be logged in to post a comment.