https://drive.google.com/drive/folders/1GBHBrkWJuy-W_8jqxPoALqsAxNbfZ7rP?usp=sharing

Deliverables:

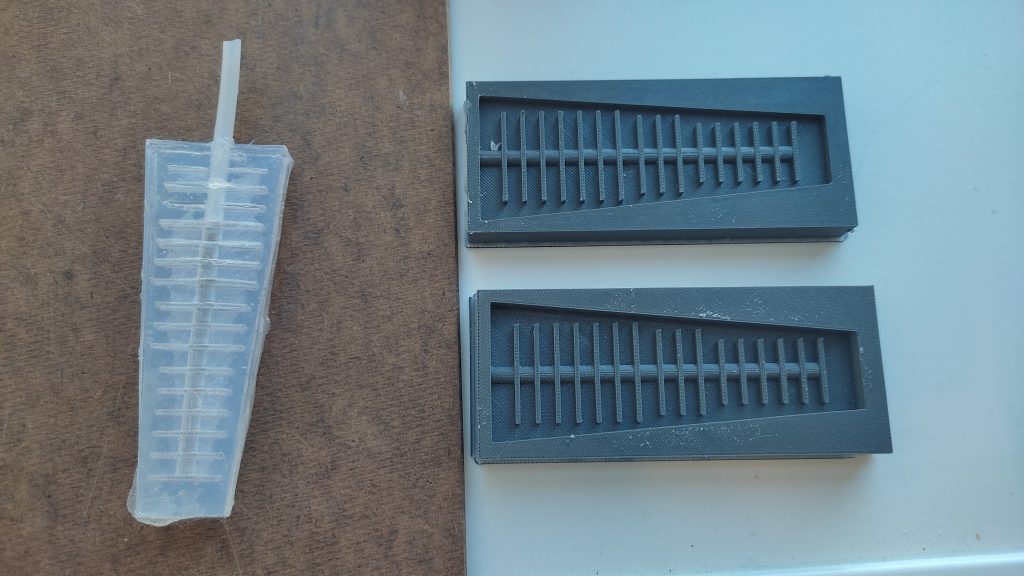

The part that was cast using Mold C appeared to be inflating well, but had air leakage in two locations oh its bottom face since the thickness of that part was only 1 mm and the cavities edges were very close to the face. I was successful in repairing these air leakages by casting small amounts of silicone, however, It was accidentally ripped open because I used too much air pressure while inflating it.

I did cast a second part in parallel to repairing that first part – this time, I used modeling clay to raise the bottom mold edges up (approximately 1 mm) – which successfully prevented the bottom face to have air leakages but appear to be slightly too thick since now the part doesn’t inflate towards one direction – as happened with the first casting of mold C. Additionally, there is one location of air leakage around the opening of the tube – as can be seen in the documentation video below. The Ecoflex silicone rubber 00-31 that was used seems to have the correct softness needed.

Changes planned for the next mold version:

- Reduce the part’s leangth and number of cavities.

- Slightly increase the thickness of the bottom part, while maintaining the unequal ratio between the top and bottom parts.

- Attempt to extend the mold to the complete structure of Whitesides’ soft robot.

Documentation: (in the video – inflating the second casted part from mold C)