Currently, we are working on fitting everything into the flower pot we bought as housing, and final wiring and testing of parts. Based on Garth’s feedback, Aditti also adjusted the code so that when 1 part is triggered, all the other parts also slightly inflate and deflate (giving them a little more life)

In class, we are hoping we can test our electronics with all the parts connected, and try fitting them into the flower pot housing.

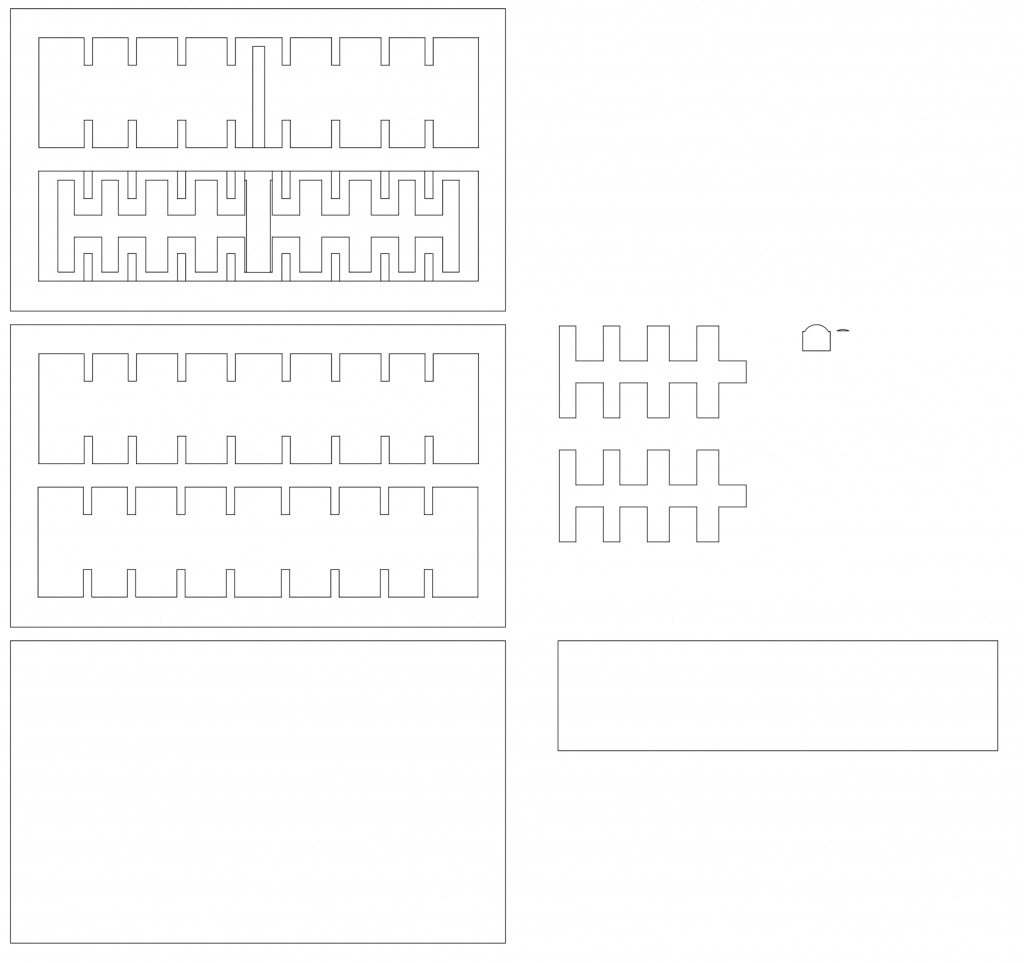

]]>We have also printed out a new mold with cuts and cast it. Since we cannot use the ideate 3D printers, we have also made plans for laser cutting some of our molds.

This week we are hoping to test out the new part and test out laser cutting as an option for mold-making. We are also planning on editing out existing models so that they can bend to a greater angle.

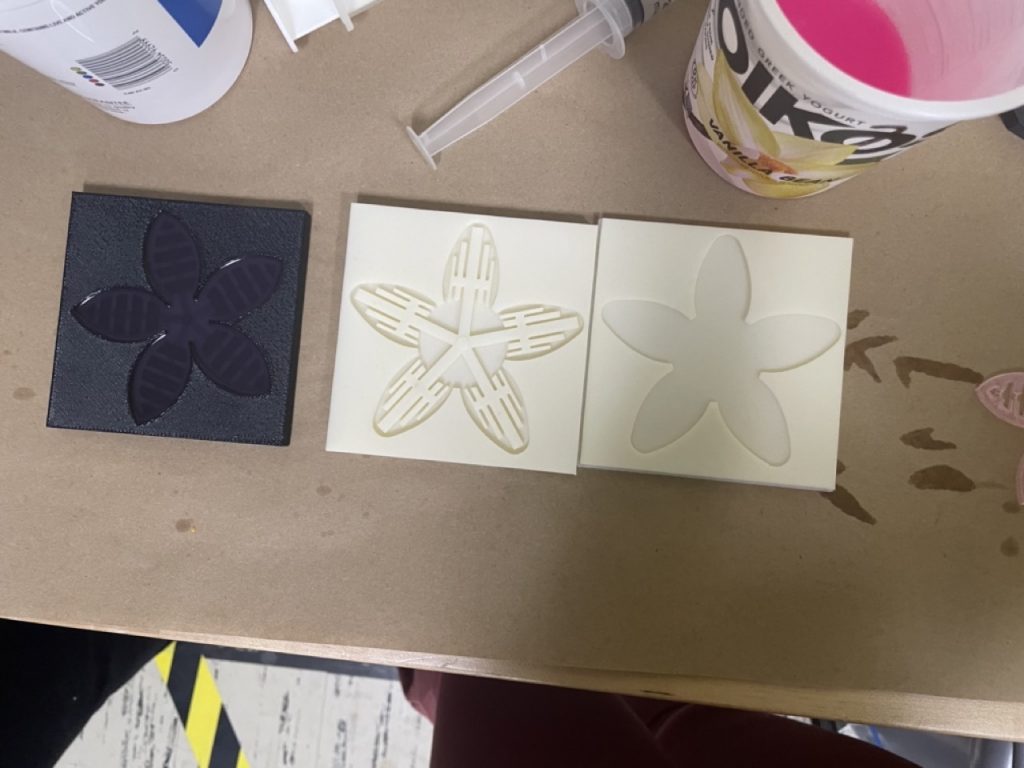

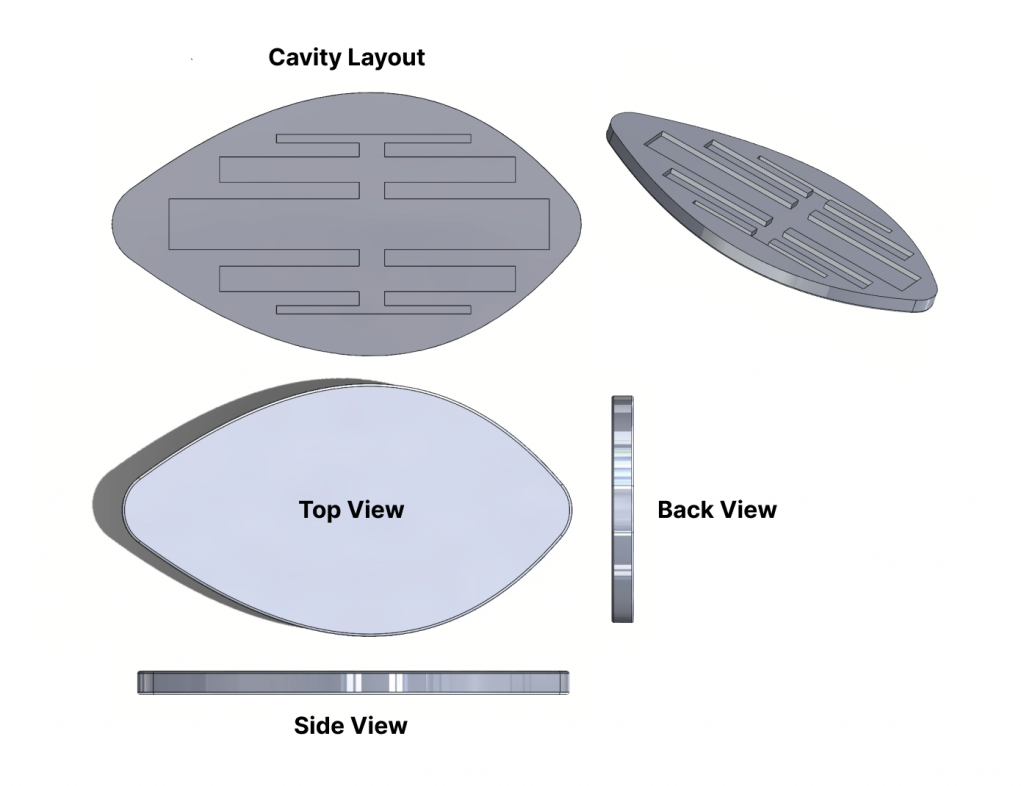

]]>We have used these models and created flowers out of them. We have also 3D printed the molds and have poured the silicone.

Since we also poured these molds with colored silicone, our hope is that when water is pumped into them, the stretched areas will have a lighter color than the thicker areas. We also plan on experimenting with pumping in colored/ fluorescent water so that it will seem as if the plants are changing color as they move.

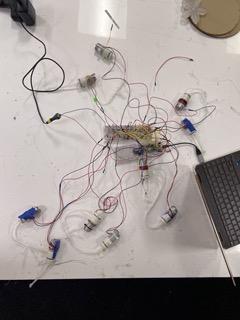

We have also tested sensors such as proximity and capacitive touch sensors to see how sensitive they are and how we could embed them into our mold castings. Our goal is that when people touch the plants, they will be activated.

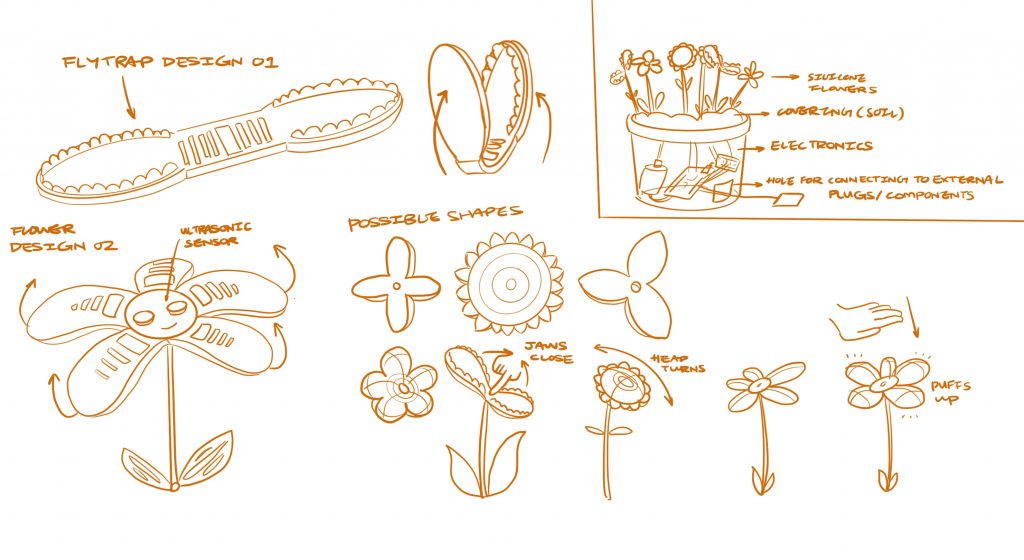

]]>We are currently focusing on developing a design that mimics the movement of a venus flytrap. When touched, its jaws will bend upwards. To do so, we have designed 2 variations as prototypes to test movement, which we have cast in silicone.

We are also investigating different ways to detect touch, such as through a CTS breakout board, ribbon sensor, and a square FSR

We also have some sketches of what we would ideally like to achieve with different flower forms and movements.

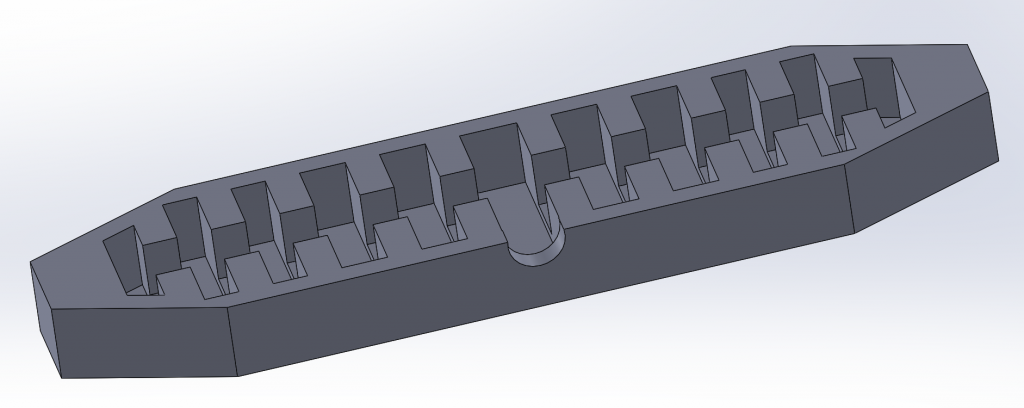

I looked at how different cavity sizes would produce different movement when pneumatically activated.

Ideally, the different sized cavities would cause the leaf to curl up when filled with air or water, which would mimick a leaf wilting. The dimensions are approximately 3inx2inx0.2in.

]]>

The project I chose to explore is Geemo: a flexible modular toy with magnetic limbs that attract and repel each other in unpredictable ways. The creator Cas Holman was inspired by natural patterns and was interested in designing units forming irregular patterns. Additionally, the magnetic limbs were left unmarked and uncolored because she felt there was something wonderful about not knowing whether any two limbs would attract or repel until you try.

Essentially, I believe she was interested in exploring creative play through simple forms and a child’s imagination. The toy’s softness helps with this in how it could bend and become different shapes based on magnetic attraction. With this in mind, I then went to find other projects with similar intent but perhaps different execution. I thought that this could include different materials or maybe different shapes.

Papers that I found that explores the movement/flexiblity of soft materials for making robots:

J. M. Bern, G. Kumagai and S. Coros, “Fabrication, modeling, and control of plush robots,” 2017 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vancouver, BC, Canada, 2017, pp. 3739-3746, doi: 10.1109/IROS.2017.8206223.

J. M. Bern, L. Z. Yañez, E. Sologuren and D. Rus, “Contact-Rich Soft-Rigid Robots Inspired by Push Puppets,” 2022 IEEE 5th International Conference on Soft Robotics (RoboSoft), Edinburgh, United Kingdom, 2022, pp. 607-613, doi: 10.1109/RoboSoft54090.2022.9762203.

J. -Y. Lee, W. -B. Kim, W. -Y. Choi and K. -J. Cho, “Soft Robotic Blocks: Introducing SoBL, a Fast-Build Modularized Design Block,” in IEEE Robotics & Automation Magazine, vol. 23, no. 3, pp. 30-41, Sept. 2016, doi: 10.1109/MRA.2016.2580479.

H. Mase, Y. Yoshida and T. Yonezawa, “An interactive stuffed-toy device for communicative description on Twitter,” 2014 Joint 7th International Conference on Soft Computing and Intelligent Systems (SCIS) and 15th International Symposium on Advanced Intelligent Systems (ISIS), Kitakyushu, Japan, 2014, pp. 1360-1363, doi: 10.1109/SCIS-ISIS.2014.7044832.

It was interesting that many soft robotic movements were inspired by toys such as the water balloon/bag, or push-puppet toys. Some papers also took advantage of soft materials to make toys or objects meant for human hugging, and how that combined with technology can help someone. I think a lot of this research could be really interesting for creating lifelike moving objects. I can imagine an exhibition where maybe there’s just a bunch of small soft robots crawling around the ground through different actuation methods. I think that will be very cool and creepy.

]]>This is a soft robotics project I found a while ago online by designer Aslak Siimes, which features a joint made of a soft material. Due to the flexibility and range of motion of this soft material, the robot is able to perform fluid and life-like motion.

I thought that the simplicity of the robot was the project’s key point. As soft materials are better able to mimic organic motion, a simple object with soft joints is still able to seem lifelike and have a personality through movement and interaction.

Therms-Up!: DIY Inflatables and Interactive Materials by Upcycling Wasted Thermoplastic Bags

Kyung Yun Choi and Hiroshi Ishii. 2021. Therms-Up!: DIY Inflatables and Interactive Materials by Upcycling Wasted Thermoplastic Bags. In Proceedings of the Fifteenth International Conference on Tangible, Embedded, and Embodied Interaction (TEI ’21). Association for Computing Machinery, New York, NY, USA, Article 51, 1–8. https://doi.org/10.1145/3430524.3442457

A project by MIT Media Lab exploring introducing a DIY method of creating inflatables and prototyping interactive materials from wasted thermoplastic bags that are easily found at home. Using a 3D printer with no customizations, the team explored various patterns, embossings, and melting techniques to prototype inflatable objects that can be used for various applications.

I think this is an interesting project as it provides a low access point to soft robotics and I can see us trying this method too for fast prototyping and testing different mechanics to create movement.

]]>M. Chen, D. Wang, J. Zou, L. Sun, J. Sun and G. Jin, “A Multi-Module Soft Robotic Arm with Soft End Effector for Minimally Invasive Surgery,” 2019 2nd World Conference on Mechanical Engineering and Intelligent Manufacturing (WCMEIM), Shanghai, China, 2019, pp. 461-465, doi: 10.1109/WCMEIM48965.2019.00097.Notes:

- Do you have any conflict of interest in reviewing this paper?

No, I do not.

2. Expertise. Provide your expertise in the topic area of this paper.

2- passing knowledge

3. Summary. Please summarize what you believe are the paper’s main contributions to the field of soft robotics.

The paper proposes a unique approach to designing soft robotic arms for minimally invasive surgery based off the structure of an octopus arm. Soft robotics is effective in this scenario as the material allows for the tool to have greater degrees of movement and move through smaller spaces to access critical organs. if developed, this technology could improve the surgical quality and time for minimally invasive surgery, and open up the option for more types of surgery.

4. Strengths and Weaknesses. What are the main strengths and weaknesses of this work? Does the paper have strengths in originality and novelty?

The paper’s strength is in its detailed presentation of information, from fabrication to testing for control and range of movement. While the material choice of silicone is novel to laparoscopic surgery, and the rationale behind the choice is sound, the actual mechanical design of the robotic arm is not too different from the designs of current laparoscopic tools.

5. Soundness. Are the ideas, algorithms, results or studies technologically/methodologically sound?

Yes, the ideas and studies are sound. However, I am not sure about the results as there is no information on how many times the tests were run or how the data was recorded.

6. Related Work. Does the paper adequately describe related and prior work?

Yes, the paper references prior research done in the field and related topics on bioinspired robots and laparoscopic arm technology.

7. Presentation. Is the paper well organized, well written and clearly presented?

Yes, the paper is well-organized with a clear introduction and explanation of process and results. Diagrams are also used to illustrate fabrication methods and test results.

8. Suggestions. Do you have suggestions for improving this paper?

The paper uses diagrams effectively to communicate the fabrication process of each part of the robotic arm. However, Figure 7 was hard to understand as there lacked some explanation/titles for what each graph was showing.

The paper also had detailed explanations and diagrams supporting the fabrication process and detailed tests were run for each module and articulation of the robotic arm. While the results do seem successful, I think it would be supported further if there were more elaboration on how the data was collected and how many times each test was run.

9. Comments to Committee (Hidden from authors). Does the paper have enough originality and importance to merit publication? Is the paper relevant to the field? These comments will NOT be sent to the authors:

I think the paper does have enough originality and importance to merit publication as laparoscopic arms made with soft materials is still relatively novel to the field. The paper also explains this in its introduction to provide some context for the audience. As the conference is on mechanical engineering and intelligent manufacturing, this paper is relevant to the field as it proposes a unique fabrication method for an engineered tool.

10. Overall Rating. Provide your overall rating of the paper (5 is best)

4 – Probably accept: I would argue for accepting this paper.

]]>From there, I found another paper citing this root paper called Assisting Forearm Function in Children With Movement Disorders via A Soft Wearable Robot With Equilibrium-Point Control [2]. Similar to the root paper, this research focuses on using soft robotics in assistive devices and conducted research with 2 invidiuals to test their mobility using the robot. While the assistive device reduced the amount of effort needed to complete a task on the user’s end, it also increased error. For future research, this could be addressed by improving the device’s coarse nature.

From the same root paper, there was a similar paper discussing motion control with soft robotics. The paper (Towards Adaptive Continuous Control of Soft Robotic Manipulator using Reinforcement Learning) [3], proposes a deep deterministic policy gradient (DDPG)-based control system for the continuous task-space manipulation of soft robots.

[1] M. Zhu, S. Biswas, S. I. Dinulescu, N. Kastor, E. W. Hawkes and Y. Visell, “Soft, Wearable Robotics and Haptics: Technologies, Trends, and Emerging Applications,” in Proceedings of the IEEE, vol. 110, no. 2, pp. 246-272, Feb. 2022, doi: 10.1109/JPROC.2021.3140049.

[2] Realmuto J, Sanger TD. Assisting Forearm Function in Children With Movement Disorders via A Soft Wearable Robot With Equilibrium-Point Control. Front Robot AI. 2022 Jun 15;9:877041. doi: 10.3389/frobt.2022.877041. PMID: 35783026; PMCID: PMC9240630.

[3] Y. Li, X. Wang and K. -W. Kwok, “Towards Adaptive Continuous Control of Soft Robotic Manipulator using Reinforcement Learning,” 2022 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Kyoto, Japan, 2022, pp. 7074-7081, doi: 10.1109/IROS47612.2022.9981335.

]]>The paper proposes a design and fabrication process for flexible robotic arms using an origami method. The origami skeleton combined with a pneumatic actuation system allows for fast activation while retaining pressure and tension. Using 3D printing is also good for different scales and is cost-effective.

K. Zhang, Y. Zhu, C. Lou, P. Zheng and M. Kovač, “A Design and Fabrication Approach for Pneumatic Soft Robotic Arms Using 3D Printed Origami Skeletons,” 2019 2nd IEEE International Conference on Soft Robotics (RoboSoft), Seoul, Korea (South), 2019, pp. 821-827, doi: 10.1109/ROBOSOFT.2019.8722719.

Modeling locomotion of a soft-bodied arthropod using inverse dynamics

This paper suggests studying the tobacco hornworm caterpillar as a model for locomotion compared to animals with stiff skeletons. Their goal is to develop a reduced-order physical model to infer how passive mechanical forces and active neuromuscular forces contribute to motion. They found that internal motion is highly localized rather than evenly distributed, which serves as

Saunders F, Trimmer BA, Rife J. Modeling locomotion of a soft-bodied arthropod using inverse dynamics. Bioinspir Biomim. 2011 Mar;6(1):016001. doi: 10.1088/1748-3182/6/1/016001. Epub 2010 Dec 15. PMID: 21160115.

A Multi-Module Soft Robotic Arm with Soft End Effector for Minimally Invasive Surgery

Current surgical procedure rely on rigid medical devices which can cause harm to the patient, so the paper reports the design and fabrication of 2 end-of-arm manipulators made of a flexible silicone rubber. The designed arms have a variety of motion modes and can grasp both small medical devices and tissue, but need more research to have better control and define range of motion.

M. Chen, D. Wang, J. Zou, L. Sun, J. Sun and G. Jin, “A Multi-Module Soft Robotic Arm with Soft End Effector for Minimally Invasive Surgery,” 2019 2nd World Conference on Mechanical Engineering and Intelligent Manufacturing (WCMEIM), Shanghai, China, 2019, pp. 461-465, doi: 10.1109/WCMEIM48965.2019.00097.

]]>