For this checkpoint, I prototyped the most favorable of my design choices for the bladder to get the movement I wanted

In addition, I tested the two input methods for inflating the columns to actuate and ideally curl around to grab an object. Inflating each column individually seems impossible at small scale and not feasible with the amount of motors required. Also, in the small scale prototype, the curl is quite extreme yet the shape works so I moved on to larger scale where I knew movement would be an issue.

The larger scale version (~24″) barely inflates and needs a very tight seal to show any movement

To get the right movement, it appears sealing funnels in the plastic forces the air in the right direction. This is closer to the desired motion but not complete. I am looking into backing the bladder on paper/cardboard to further accentuate this motion and am testing hinges as a possible less complicated alternative to still get the effect of two arms gripping ground or objects. This larger scale version will at least require more motors as the bags require more air. I have been experimenting with both the pleats, shiny, and fuzzy/hairy fabrics to see what effect they can create when inflated/actuated and will likely go with a combination of pleated and hairy.

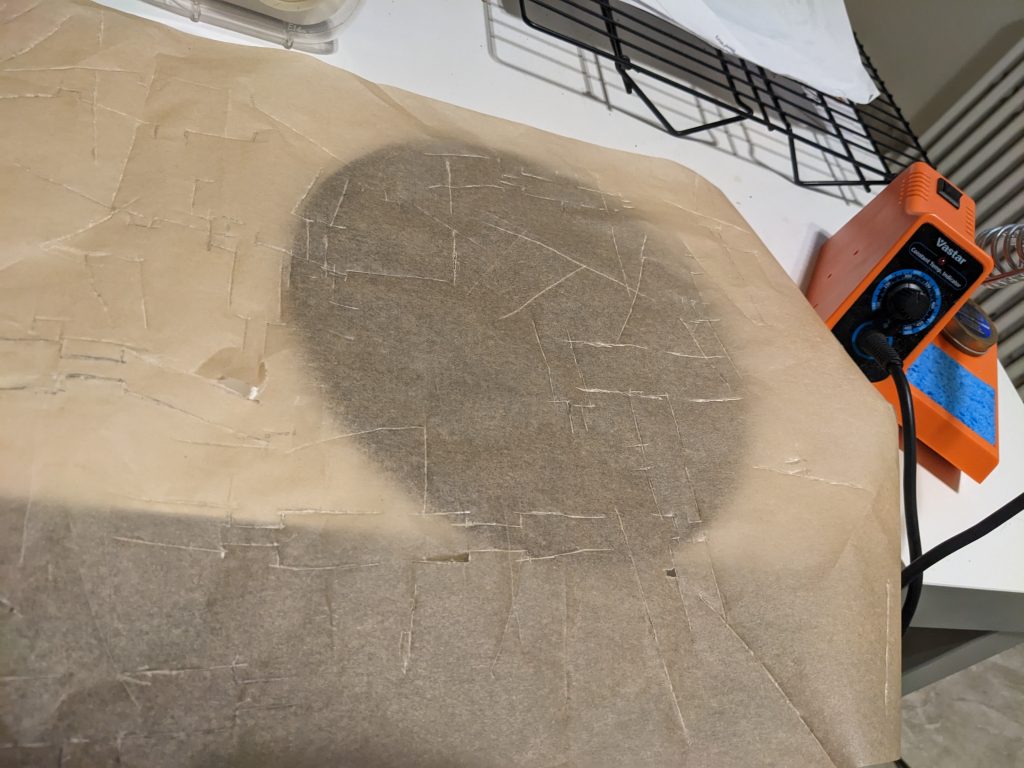

I found success with 300°F and a sheet of parchment paper as advised which takes some practice; however, the soldering iron allows for quicker prototyping and easier right angles without sealing over already existing pockets.

Leave a Reply

You must be logged in to post a comment.