Four Week Plan

| Week | Goals |

| 4/12 | 1. Acquiring wax |

| 4/16 | 1. Have a working bistable connection |

| 4/23 | 1. SLA printing connector piece 2. Getting a wax mold to work |

| 4/30 | 1. Tuning the molds to get the desired motion |

| 5/7 | 1. Tying up loose ends 2. Final Documentation |

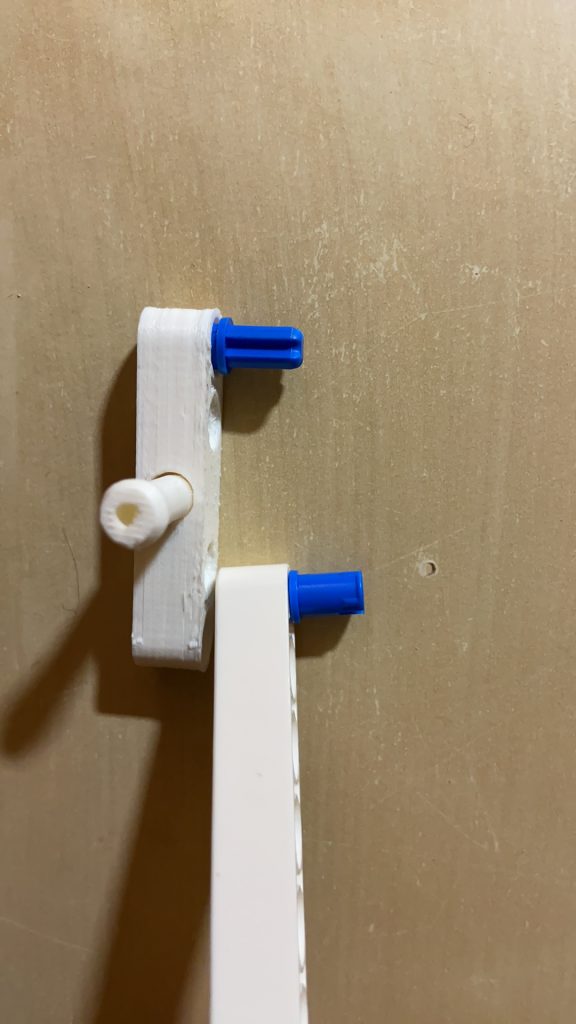

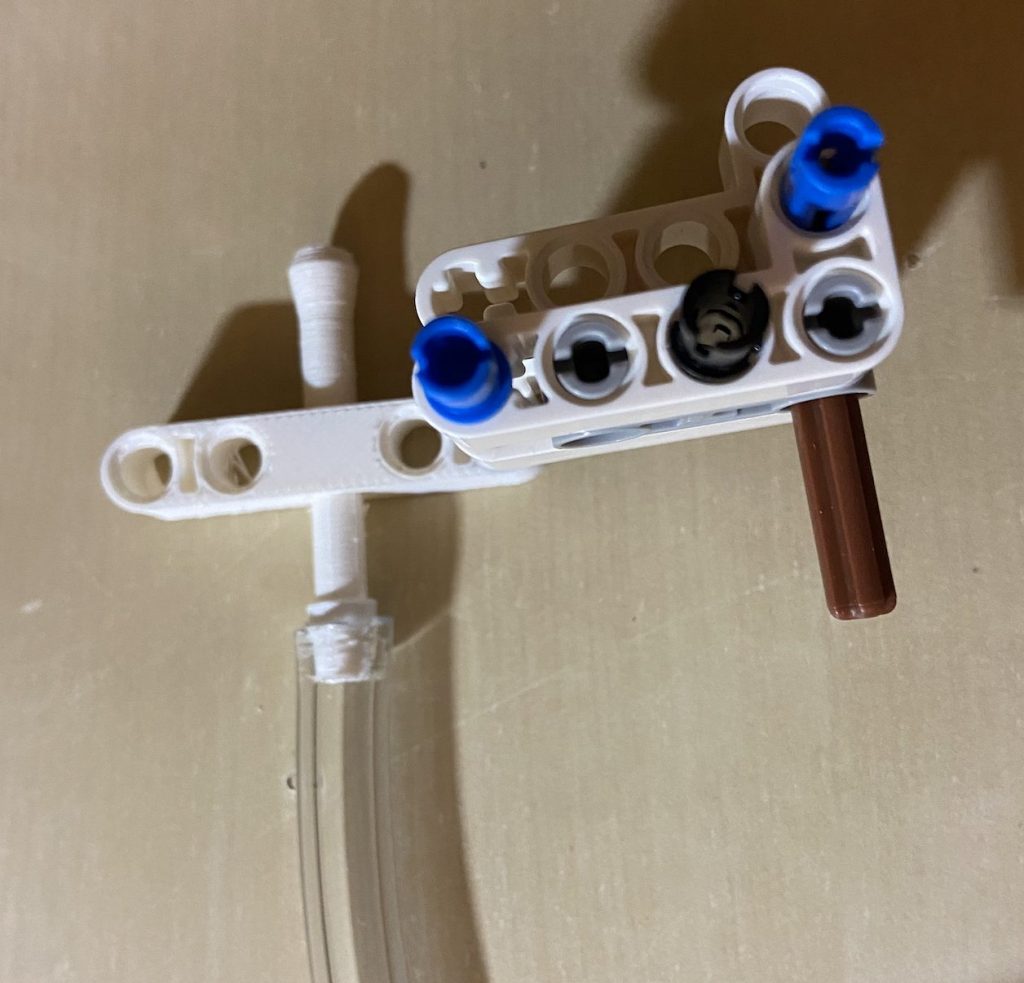

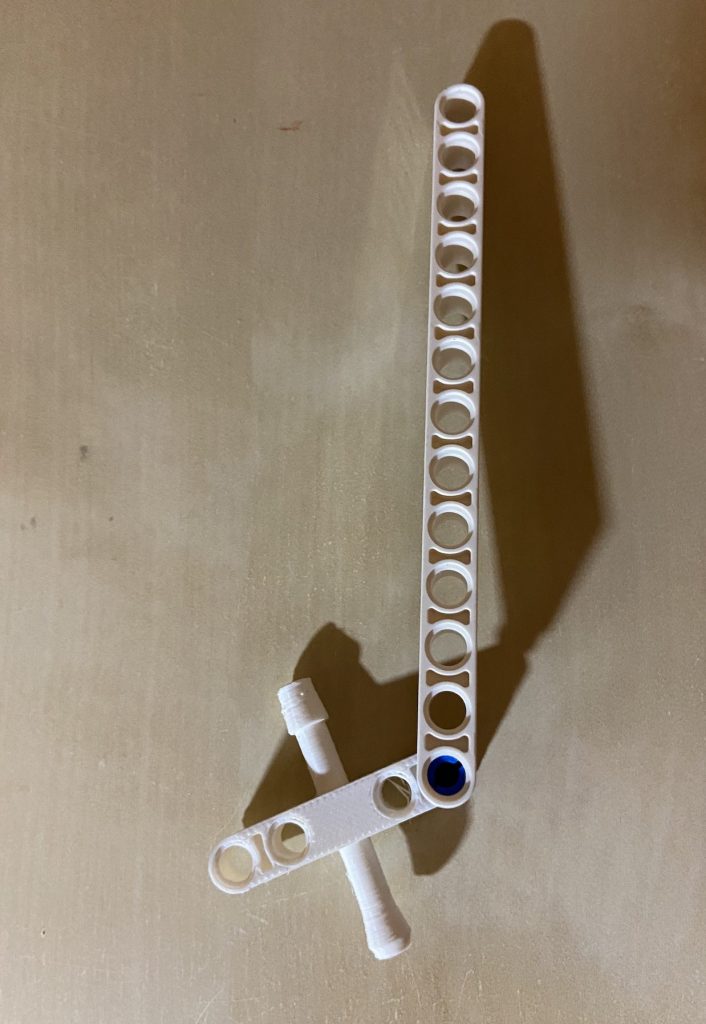

ABS Lego parts: Trial One

Our printed Lego parts are very close to working. The tolerances are almost correct, but are just barely too tight. We are considering changing our CAD tolerances slightly, but we are also considering moving forward with SLA printing rather than FDM in order to achieve a more consistent tolerance to match with the tight tolerances of Lego parts.

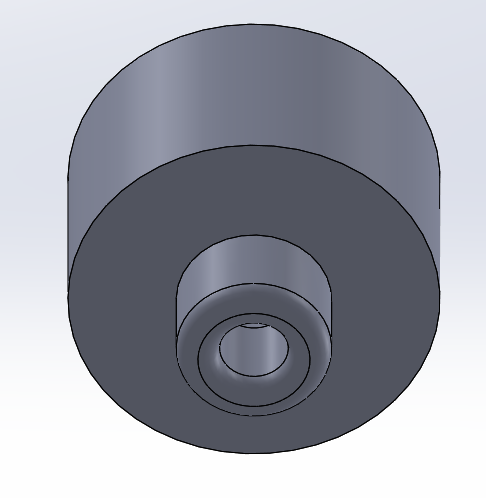

Bistable Connection Progress

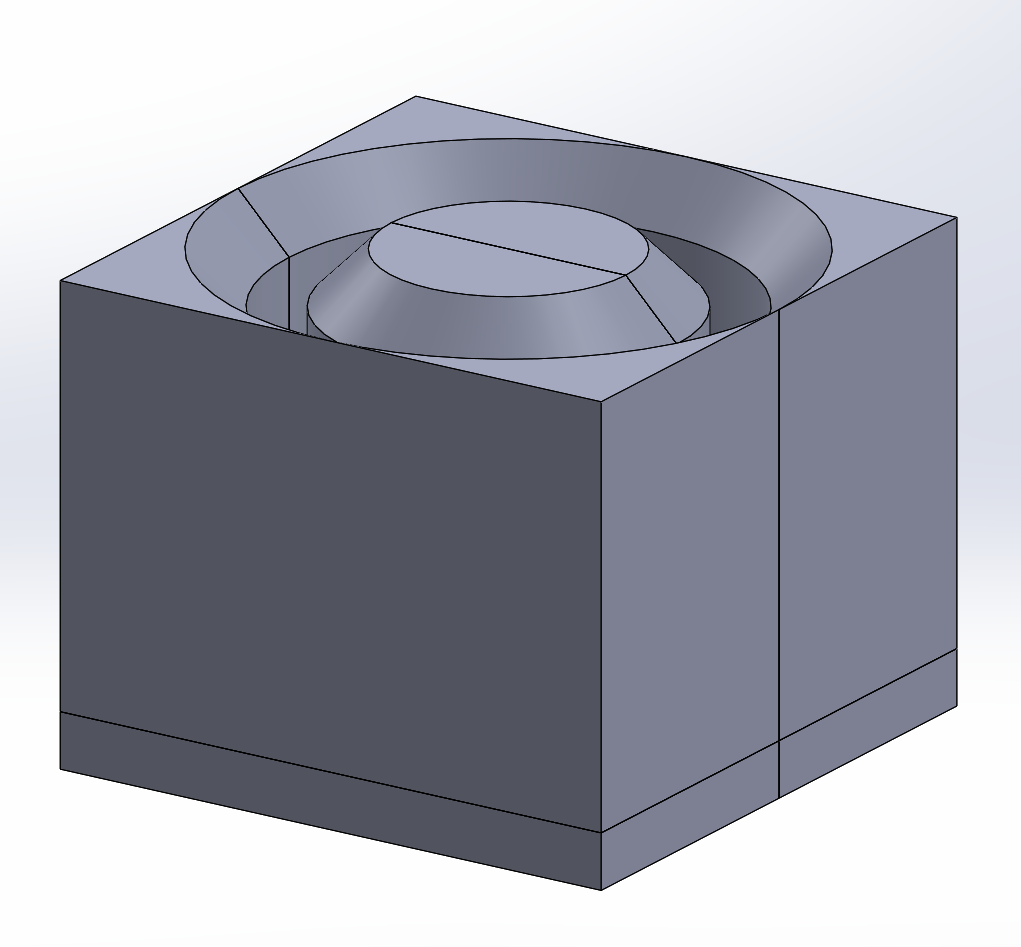

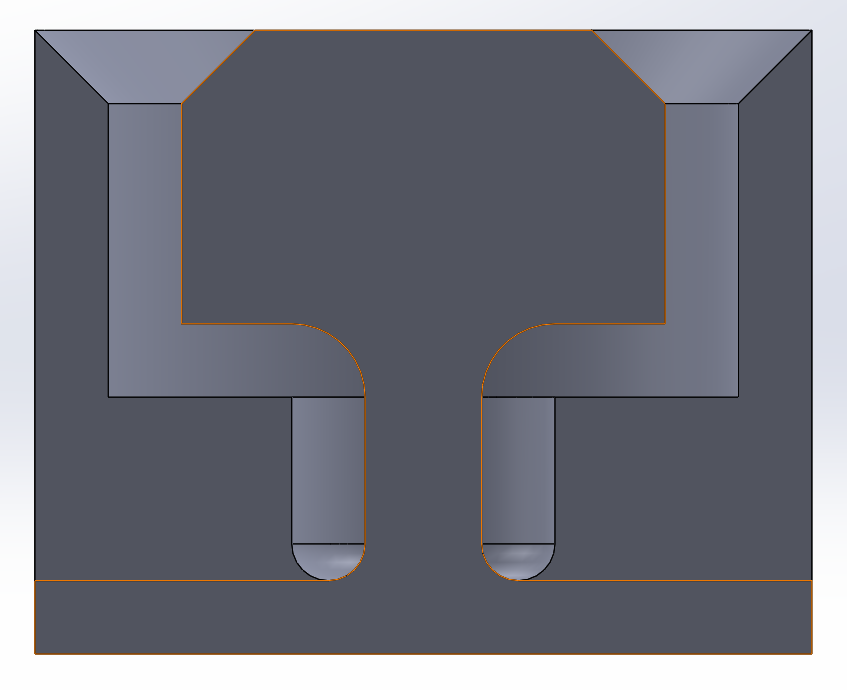

We’re currently trying to make progress on the bistable connection mechanism for our silicone parts. We’ve designed a preliminary mold design for our prototype connection, but Sebastian’s printer broke again, so we are currently waiting on a print from the Ideate printers to cast and evaluate the functionality of this design.