Progress Update:

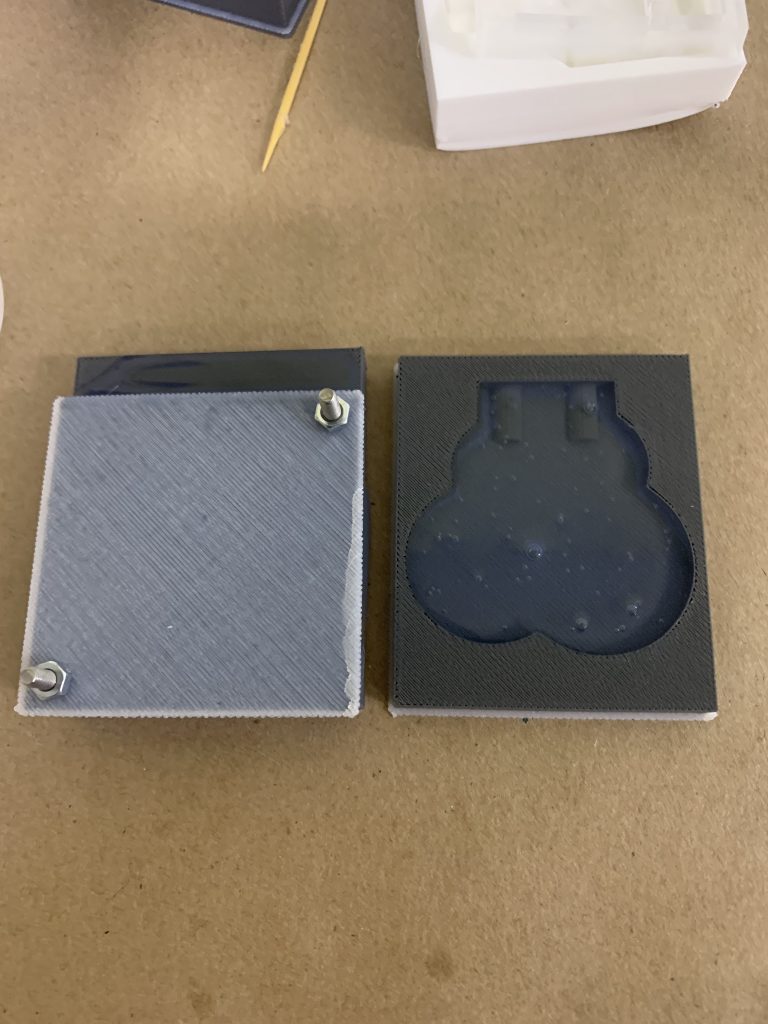

This week I attempted to make a 2-part mold version of the heart I made previously.

As you can see, the right half of the mold had a bunch of bubbles, but this ended up not being an issue at all for that half of the mold as almost all the bubbles popped and weren’t cast in the mold, but might have contributed to the issues I had with the two part mold. Unfortunately, my two part mold didn’t work totally correctly because of a big bubble on the right side (pictured below). I play to try to correct this by filling in the area with silicone, but I haven’t had the chance yet to do this.

Daniel

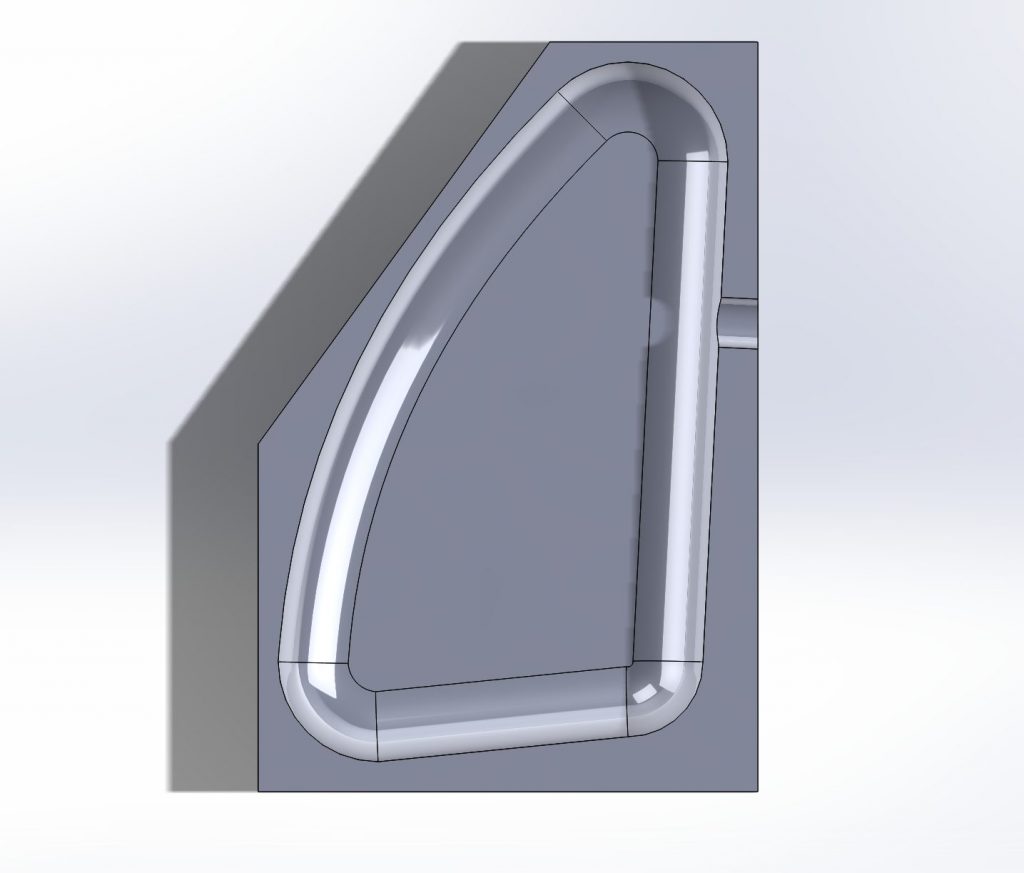

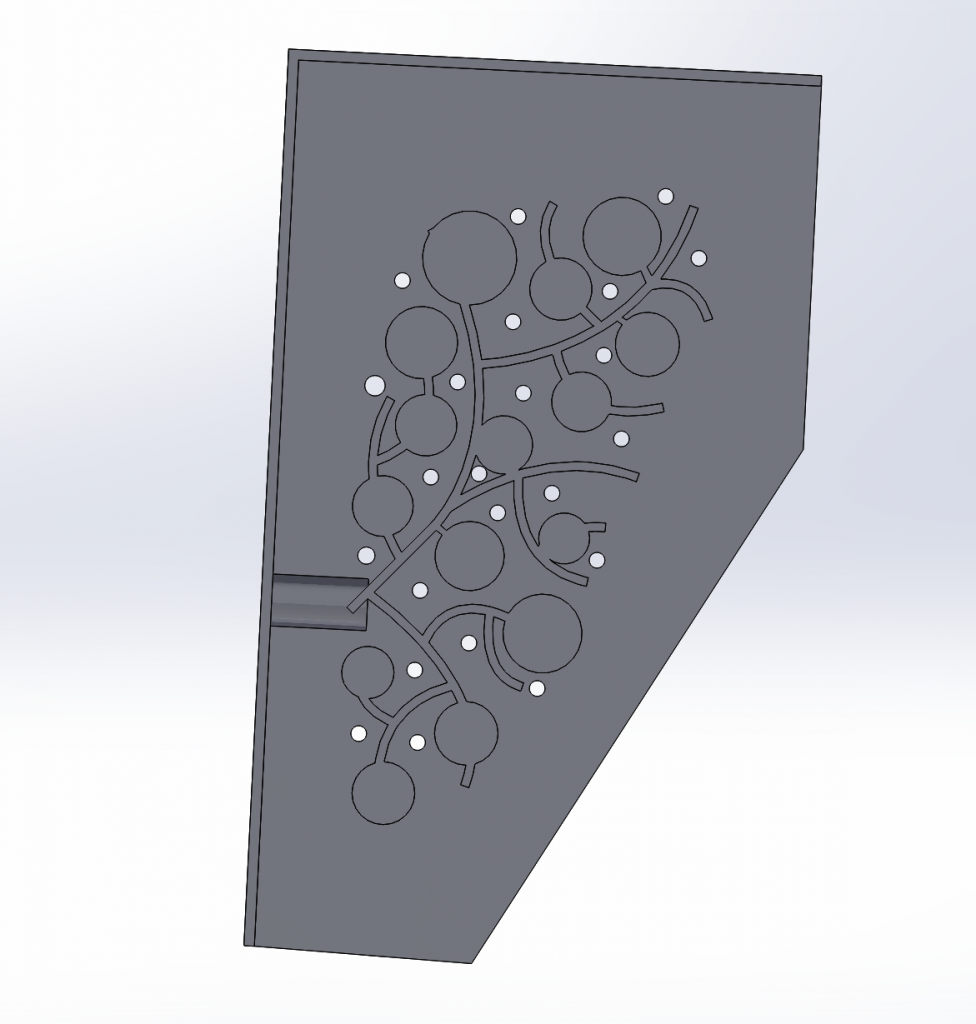

This week, I modified my previous attempt at two part mould by making adding a ceiling to the texture with holes throughout the top of the structure. The plan was to fill the bottom half of the mould with silicone then press the top half down into the liquid. The excess liquid would then be pressed through the holes on the top while the inside shape remains. Here are the Solidworks files:

Unfortunately, the process did not turn out as I hoped. Although the texture ended up in the right place, the silicone ended up not being flush to the surface again. This seemed strange to me because I added enough silicone for it to spill out the holes on top as planned. However, this issue still occurred. The placement of the holes prevented large pockets of air from being trapped during the process of pressing the texture into the mould so I suspect if might have something to do with the surface tension of the silicone drawing it closer onto the textured parts of the top mould, although this is just a guess.