Inbar:

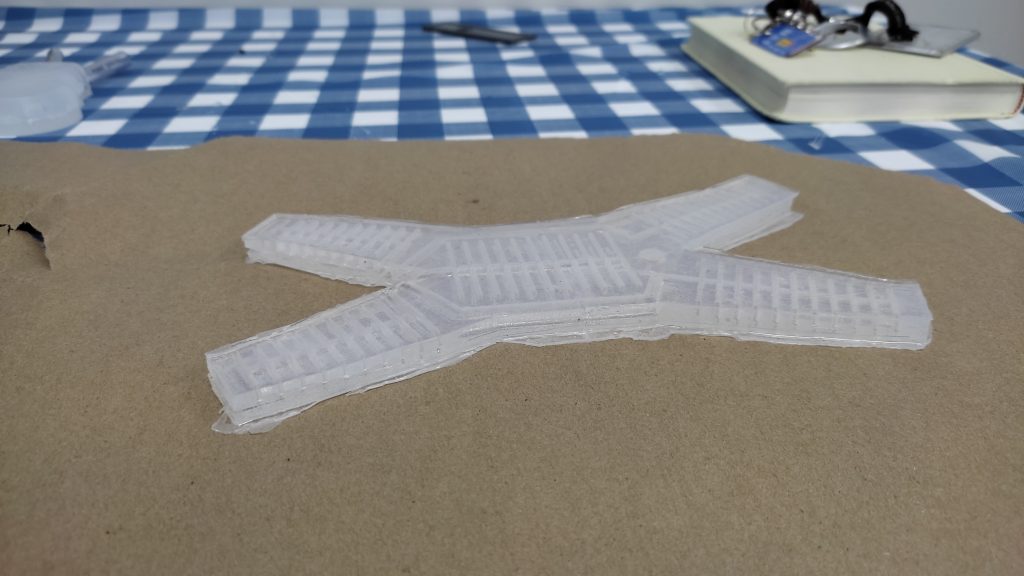

This week I attempted the full robot fabrication again. I was successful in creating the divided molds parts and then glueing them together –

After that, I tried casting the silicone and bonding the top and bottom. Unfortunately, non of the parts in the model I cast inflates properly – it seems like air is slipping out, and that the internal cavities didn’t bond well enough. Additionally, I think the transparent film I used in the bottom part sank too low and disturbed the cavities, so next time I will try casting 3/4 of the bottom part, and then wait until it is almost cured before adding the transparent film and casting another layer of silicone.

Jason

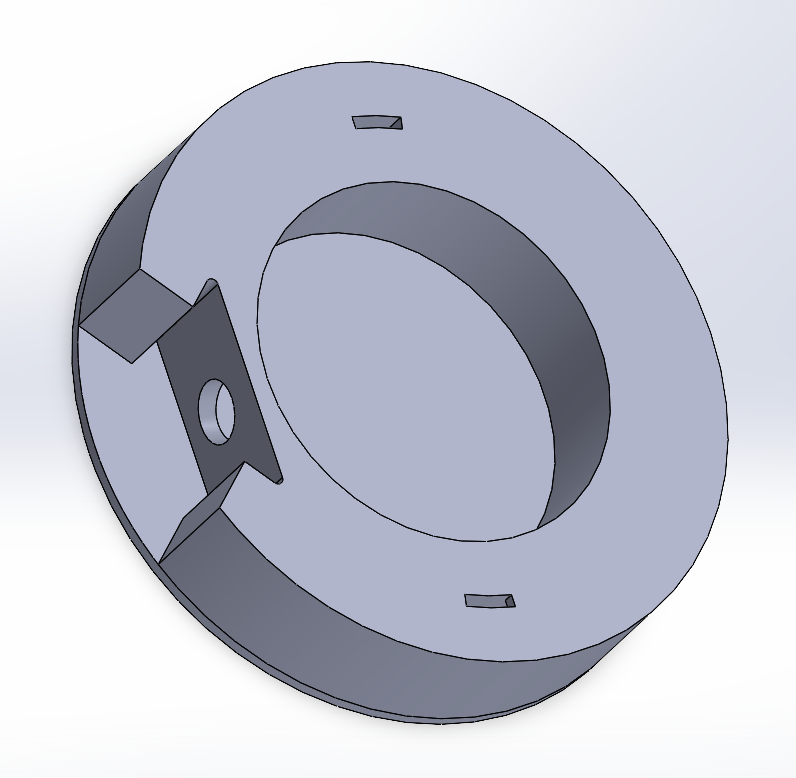

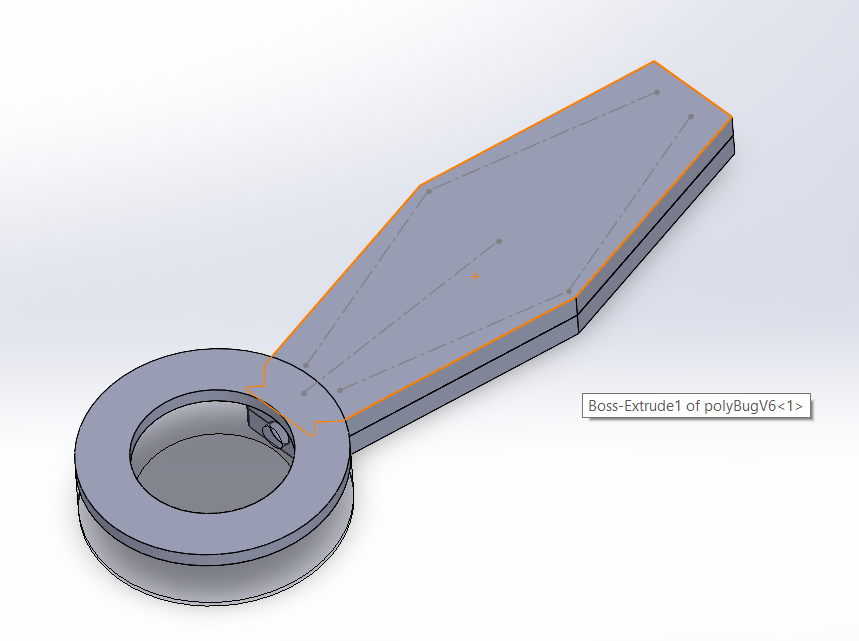

This week’s iteration focused on developing a design that would allow soft and rigid parts to connect. Rather than creating a soft center unit, I opted for creating a central module that will allow for flexibility in the number of appendages for future iterations. This week’s iteration only had one attachment port but more can be added fairly easily. Unfortunately, a design flaw was revealed once the print was finalized. The locking mechanism for the lid was too small and the hooks did not print on the lid.

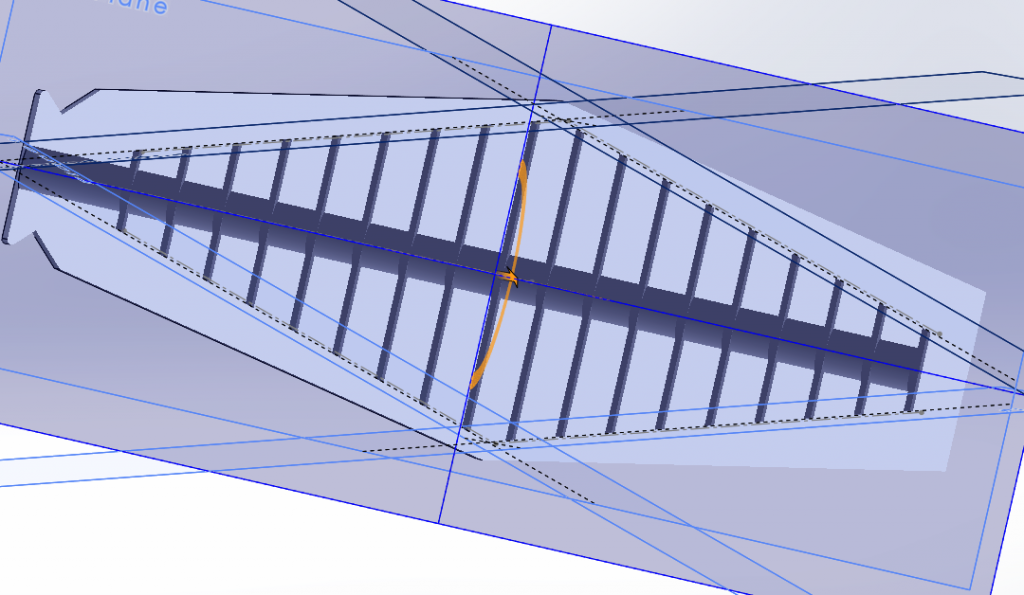

The other change consisted of modifying the latest iteration of the appendage to include the locking design. The process was very similar to the previous iterations.

Due to a lack of time management, I was unable to complete the part by Sunday. However, all that is left is to bond the pieces on Monday. Once that is done, this report will be updated with video and photo documentation.