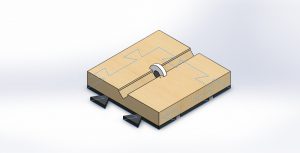

This project taught us all different things. The most important thing we learned was how to improvise at the last second. We planned on creating the tracks on the CNC router, and had learned HSMWorks to create the G-code necessary to create the part. However, when we went to use the CNC, we realized that the shop was not open that day. After a moment of panic, we regathered ourselves and decided to laser cut instead. The final product was not perfect, but it worked very well. This taught us all an important lesson: don’t be afraid to improvise.

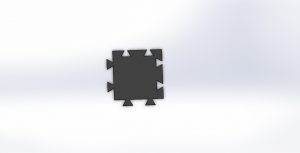

The only manufacturing process (besides gluing) was laser cutting. Half of the group had never used the laser cutters before, so they learnt about that process. In addition, the group used CAD software to design the project. This was a new experience for some of the group members, who learned a bit of CAD for this project. For the more experienced group members, they learned how to use HSMWorks to write the GCode to use the CNC router.

The group worked well together. We worked to each others’ strengths and were all receptive to different ideas and approaches. Everybody held everybody else accountable for their work while still being supportive and understanding. Through this project, besides the technical knowledge gained, we all gained more experience working with a group on a large project. This was valuable as it helped our communication and teamwork skills. Overall, this project was a valuable learning experience for this group.