video: https://youtu.be/xAO66SjFdWg

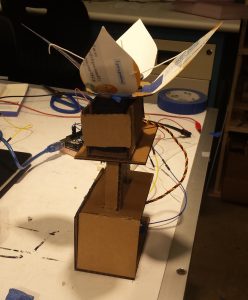

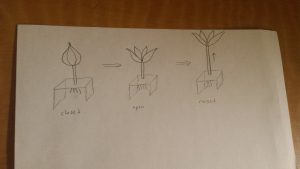

My final project is a play on a flower. With this project I wanted to present the idea that living things need human connection just as much as the usual basic essentials for survival. So light and water are replaced by physical closeness and touch: when you come closer or further away, the petals open and close, and “water” travels up the roots when you touch the base. The first part of the title comes from a quote from The Prophet by Kahlil Gibran, which describes how a bee and a flower depend on each other through their interaction.

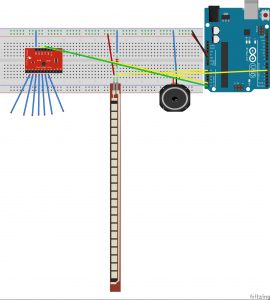

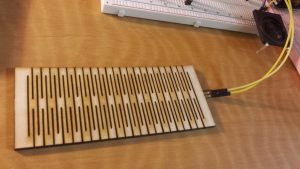

Components: The open/close motion is controlled by a servo motor attached to each petal by wire. The petals and hinges are laser-cut basswood, the base is foamcore, and the root outline is cotton fabric. The LEDs are controlled by a standalone momentary capacitive touch sensor, and the servo motor is controlled by an ultrasonic distance sensor.

The biggest changes I made from my initial prototype were the petals, the base box, and replacing the linear actuator with lighting of the roots. I chose to replace the upward motion because I thought it wasn’t very graceful, and I felt that representing water with lights would be more effective for my purpose. I had some trouble wiring up NeoPixels, so decided to use regular small LEDs instead. I also had some trouble converting my petal drawing into dxf, but it eventually worked with some help from the Soft Fabrication class.

fritzing and sketch: final_project_NinaPrakash