Problem

In the manufacturing of physical goods, it is often difficult to test for small defects. In the case of products such as rubber cycling tubing, small, hard to detect perforations can become much more troublesome for clients in the lifecycle of the product. Additionally, it can be difficult for active cyclists to focus on identifying non major leaks and gradual changes in tire pressure on long rides.

Solution

A mounted sensor array focused on detecting both leak frequencies and changes in tire pressure can be used to streamline the tire quality assurance process, and help signal the need for tire patching or tubing replacement on the fly for cyclists. Using microphones to pick up sounds within common frequencies for leaks, as well as using an air pressure sensor to track significant changes from an ideal benchmark can be used in concert with visual indicators to help identify tears and deformations.

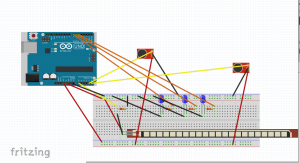

Proof of Concept

The sensor array would have a visual indicator tied to each sensor to attempt to give users an idea of where a leak would be happening, or if tire pressure was being lost. After attempting to use an LCD to provide descriptive error messaging, I decided to use a series of LCDs in concert with microphones to simulate air pressure leaks, as well as a flex sensor to simulate an air pressure sensor.