Similar to Micheal Hansmeyer’s Subdivided Columns, today I will be exploring another column design through computational fabrication. “Concrete Choreography” by ETH Zurich’s Master of Advanced Studies in Digital Fabrication program. Concrete Choreography can be compared to Hansmeyer’s Subdivided Columns in appearance as they are both ornate and have intricate patterns throughout; however, the construction methods are very different. Hansmeyer prints out sheets and links them together with a rod while the entire Concrete Choreography was 3D printed by one system. Through digital fabrication breakthroughs, ETH Zurich’s Masters students were able to revolutionize the construction of intricate material. The two main methods of digital fabrication are through subtraction or addition. ETH Zurich’s Masters students fabricated their columns through addition while Hansmeyer fabricated his work through subtraction. I admire the effort and innovation thinking that goes into Concrete Choreography and how it elevates the surrounding as a new one to fabricate buildings. This allows many new possibilities for material development and structural breakthroughs.

Category: LookingOutwards-03

LO – 03 : COMPUTATIONAL FABRICATION

Chalgrin by Quadri Fiore Architecture is an exploration on mesh sheets and wood-skin. The elegantly tessellated design creates a unique experience as an entrance and almost seems to warp the space.

The tessellation seamlessly flows with the space, so much so that the design takes even windows, arches, spotlights, and doors into consideration. This project was executed using Quadri Fiore’s custom MESH-SHEETS, which allow for the structure to wrap around the space the way that it does. The firm utilised their own program where they were able to abstract and manipulate the fabrication as needed.

This form of “wood-skin” is very commonly seen, especially in architecture. Creating forms which appear free flowing and random are often products of complex and intricate iterations, based solely on a system which allows for forms to be organic.

LO 03: Computational Fabrication

Interestingly, I already selected a piece of generative art producing a physical counterpart in last weeks Looking Outward assignment. As I mentioned before, generative art seems to be most interesting to me when it can be applied in a practical function. To widen my appreciation for such creations, I chose this week to look at another of Joris Laarman’s works, this one with that is may be be even further from practical application, but it looks cool – the Strange Attractor Lamp (2016). This lamp used randomly generated three dimensional curves using attractors. As Joris Laarman says it, the chaotic lines developed in a digital three dimensional space are “transformed into functional volumes”. The digital information is 3-D printed in aluminum, finished by hand, and fitted with LED lights. This lighting fixture demonstrates Joris Laarman’s sensibilities because he seems to be drawn towards digitally developed organic looking shapes and has used several different algorithmic approaches to reach this end. I happen to also really enjoy the blend of digital and organic, so I greatly appreciate these explorations of his.

Looking Outwards-03

Last week I reviewed, the art made by Jessica Rosenkrantz and Jesse Louis-Rosenberg. I said that although the patterns they made were unique, the forms they applied them onto were very generic. Daniel Widrig also makes functional art (furniture), but the forms he generates seem more abstract and natural than the ones mentioned before. There’s more depth to his designs which I like it’s not all on the surface so you can look at this thing he made from a number of angles and it will still be interesting. It says that he used software/technology used by special effects artists to make his 3D printed art. I would guess that he used Maya for some of it because in his description it says he was named “Maya Master.” My friend is a special effects major and she uses Python to code in Maya so if he does use code to generate his forms rather than make them entirely in Maya, then that’s probably what he’s using.

Looking Outwards-03

https://n-e-r-v-o-u-s.com/projects/albums/kinematics-dress-1/

https://n-e-r-v-o-u-s.com/projects/albums/kinematics-cloth/

Kinematic Dress

This project was created by Nervous System (Jessica Rosenkrantz and Jesse Louis-Rosenberg) in 2014. They created and used a parametric body modeling software along with another digital tool to digitally create the pattern for this dress and then used a complex physics algorithm to digitally “fold” the dress to print in one piece. The result is a 3D printed dress that can move and flow with you. Somehow they were able to take a material so rigid and structured and transform it into something fluid and soft. It reminded me of looking at a marble statue that was carved to show soft flowing fabric. This is not only a huge achievement for design, but also an achievement for physical objects/materials and the ways that we can use them in the future. I admire their focus on materials and passion for taking a material and transforming it into something totally different. This project inspires me to rethink materials and the possibilities for what they can do. I don’t fully understand the algorithms and computation they used to create this project, but I appreciate their user focused approach through the parametric body modeling application. They are both inspired by patterns found in nature and that shines through the patterning in the dress and the algorithm for how each of the pieces hinge on one another. Patterning in nature can teach us a lot and I admire how they utilized that in this piece.

LO-03

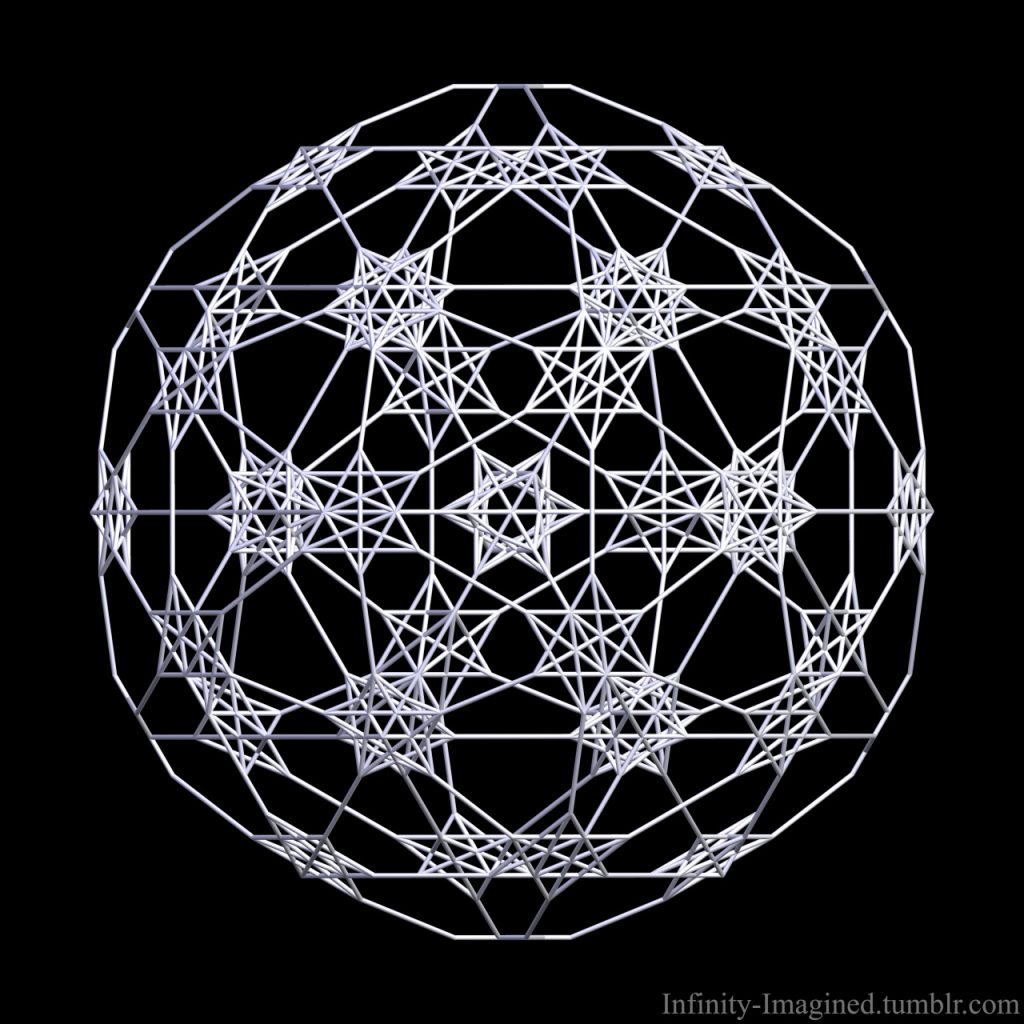

For this week’s Looking Out, I have decided to pick James Tyrwhitt-Drake’s 2015 creation, 4-Dimensional Polytope visualization. A polytope is a geometric shape that has flat sides. Personally, I find this project admirable because I have been interested in visualizing shapes of greater than 3-dimensions for quite a while. As such, I appreciate this visualization a great deal. I am unsure about many of the algorithms that generated this work, but I can assume that many of the parameters of the polytope depend on its number of points, sides, and viewing angle of the polytope. I also believe that, because a polytope is constructed using lower dimensional shapes, the number of points is actually represented by shapes like that one seen below. Although we are unable to truly see what a 4D shape would look like, I find it very interesting that we still have ways to visualize them.

LO-03 Generative Physical Forms

Iris Yip iyip

15-104 Section D

LO-03

[Mild Trypophobia Warning! Please do not click on any of the links if you are sensitive to the subject matter. Thank you for your understanding!]

This week, I looked at ‘Colony‘ by Nervous Systems, a project where the artists combine the use of 3D printing, data visualisation, and the use of a virtual environment to explore coral reefs in nature as a look into how generative sculpture/design is used to visually represent/mimic aspects of nature. The project is currently ongoing, but like many of their other works/series, Nervous System utilises custom software in order to algorithmically depict generative growth.

It is currently an ongoing project, and their current focus is on extrapolating and replicating the “lives of colonial, sessile invertebrates”; hence the name, “Colony”. I found this project really intriguing as their ingenious use of computational fabrication to study; and to some extent even replicate, nature indicative of the possibilities generative/algorithm based design can bring to our physical world.

LO-03 PHYSICAL GENERATIVE ART FORMS

The role of computational design on furniture design has been developing and advancing the limits of furniture. QERMEZi’s Futuristic Furniture expresses realistic versions of futuristic furniture through elements of futurism aesthetics. Designers investigate elements relating to outer space, linearity, biomimicry, organic forms, asymmetrical low gravity forms, etc. These collaborated with functional purposes are explored through dynamic experimentation of form, surface, and material.

QERMEZi uses Rhinoceros for their design software. Rhino allows intricate modeling of organic shapes and Grasshopper aids in the computational and parametric formations of geometrical shapes. Using this 3D software, QERMEZi is able to visualize complex structures and explore parametric design to produce furniture that challenges aesthetic, functionality, technology, and purpose.

The final form of QERMEZi’s furniture designs is conceptualized and manufactured through profound research in ergonomics, material science, computational science, aesthetics, geological studies, and social sciences. By allowing furniture design to reflect various contexts, QERMEZi is able to produce a product which abstracts these collective experiences.

SANAM CHAIR- QERMEZi.L.L.C

LO-03

Bearth & Deplazes Architects designed a building for a winery that was built using a robotic production method that a team developd for this purpose. The technology helps to lay 20,000 bricks at exact measurments for both practical and design purposes. From a practical standpoint, the building allows for a very specific amount of natural light and airflow permeation, considering that a large room in the building is used for fermenation, but that there is also a terrace at the top of the building for wine tastings and social events. The architects are also able to utilize this design precision for their artistic senses as well. They program the bricks to be rotated in a way that looks like grapes. The vertical concrete structural pillars look like a basket, so the artists say that the side of the building is intended to replicate a basket of grapes.

I selected this work because I like how the building combines art and practicality: the winey could have built any box-shaped building for their fermentation room, but they chose something a lot more interesting and visually appealing.

A winery in Switerland; Bearth & Deplazes Architects and Gramazio & Kohler (2006)

Looking Outwards-03

I chose a digitally fabricated art piece by the group FIIDAA Art, which was created by the artist Cha Jong-Rye.

The work resembles a crumpled piece of fabric or paper, but is entirely composed on laminated plywood sheets.

I assume that the form was generated in some sort of three dimensional modeling software, such as Rhino3d or Maya

using parametric inputs. In terms of the fabrication, the model was split into many thin layers the same depth as the

plywood sheets. Then, each sheet was individually cut by a CNC router and then laminated together to created the final

form. I chose this work because I have made work with this same process, but at a much smaller scale.

![[OLD FALL 2020] 15-104 • Introduction to Computing for Creative Practice](../../wp-content/uploads/2021/09/stop-banner.png)