Overview

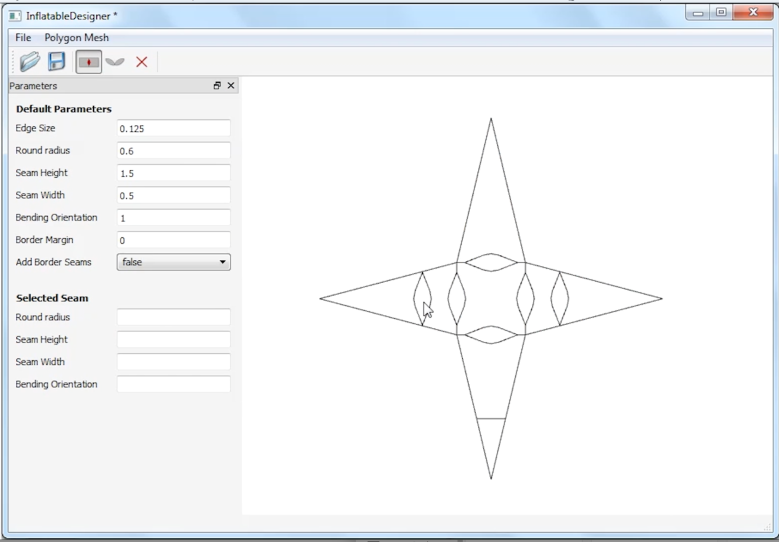

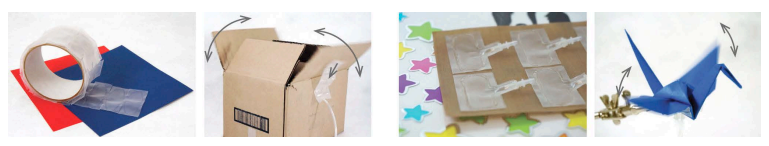

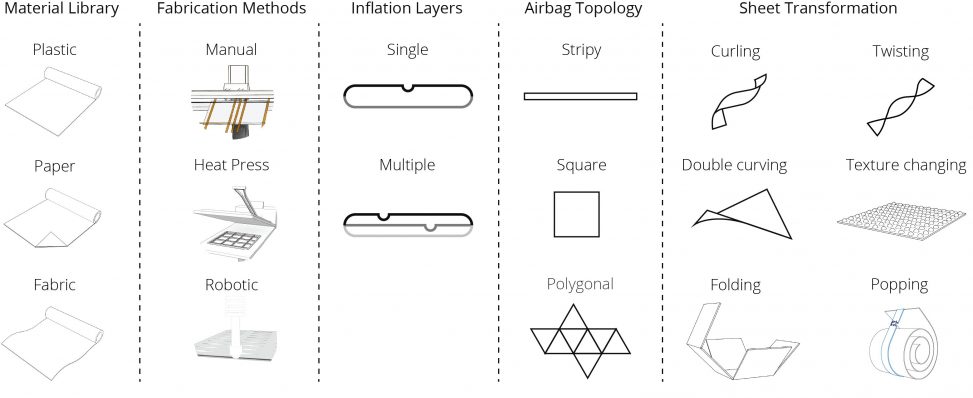

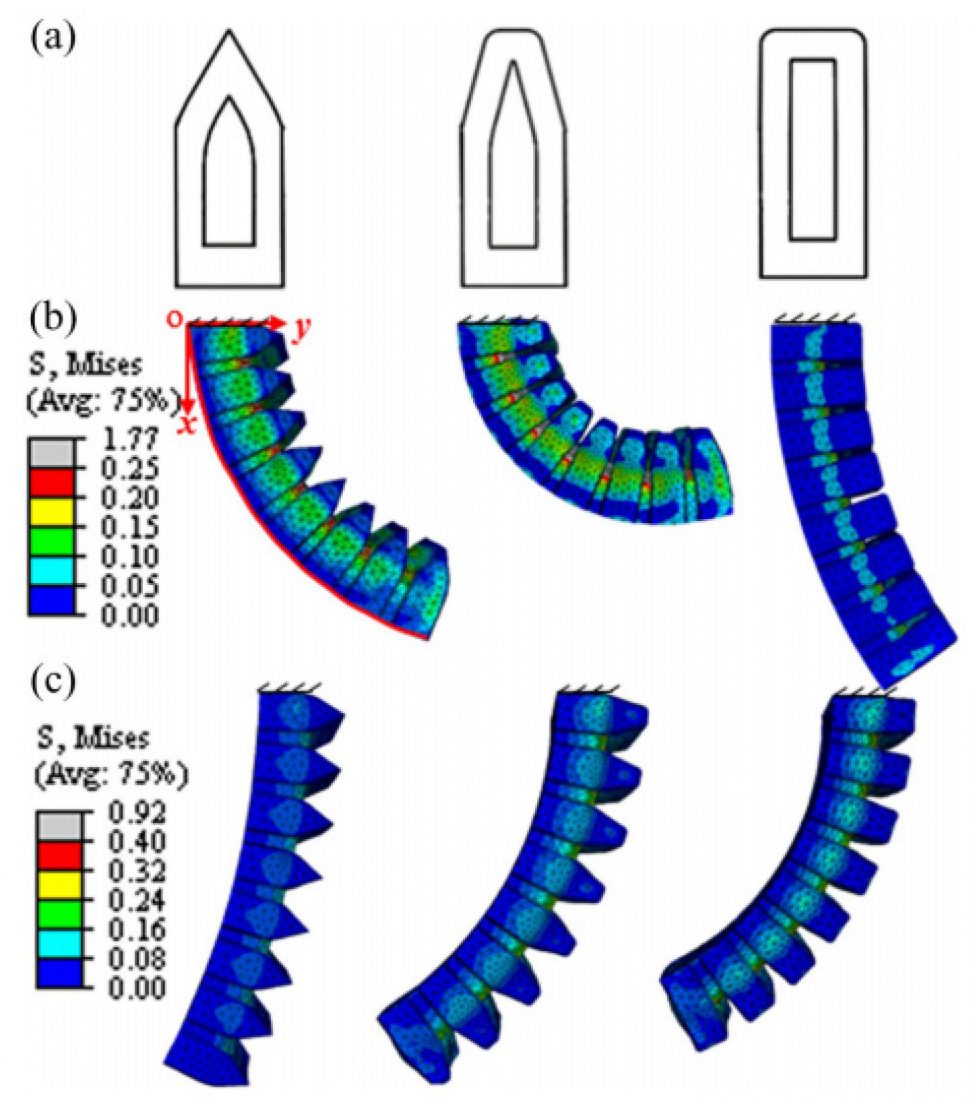

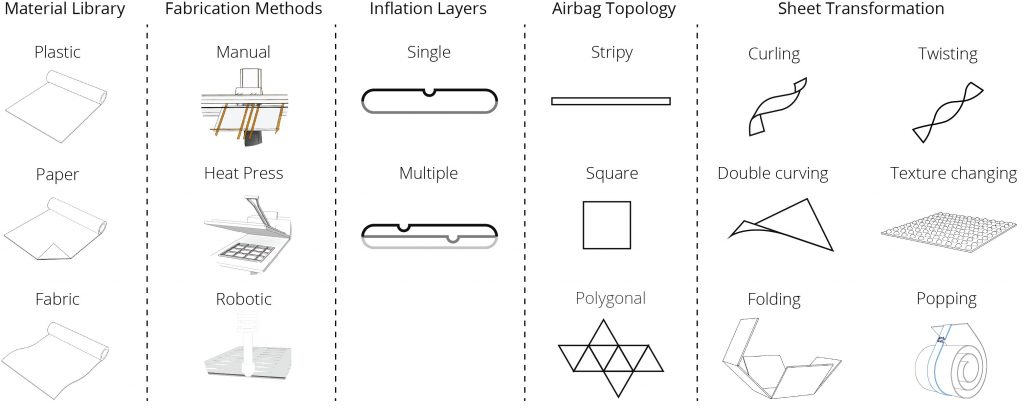

A completed design and manufacturing process for converting sheets of material into 3D objects using pneumatic actuation. This research introduces a universal bending mechanism design platform and manufacturing procedure to create programmable shape-changing behaviors with paper, plastics and fabrics.

Questions for Discussion

What feature of the work could we specifically evolve into a technique for wearable kinetic sculpture or costume?

Creating seams and creases in a material to allow it to be manipulated into multiple directions upon pneumatic actuation.

What details of the artist or concept are not immediately apparent and how do they inform the work?

This project points at any one specific application, therefore the work informs us that the design process is subject to the maker’s will. The simplicity serves as a platform for creating.

Closely related works

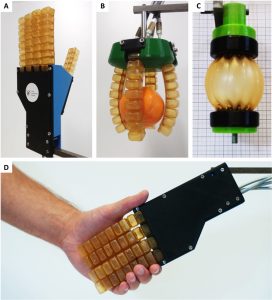

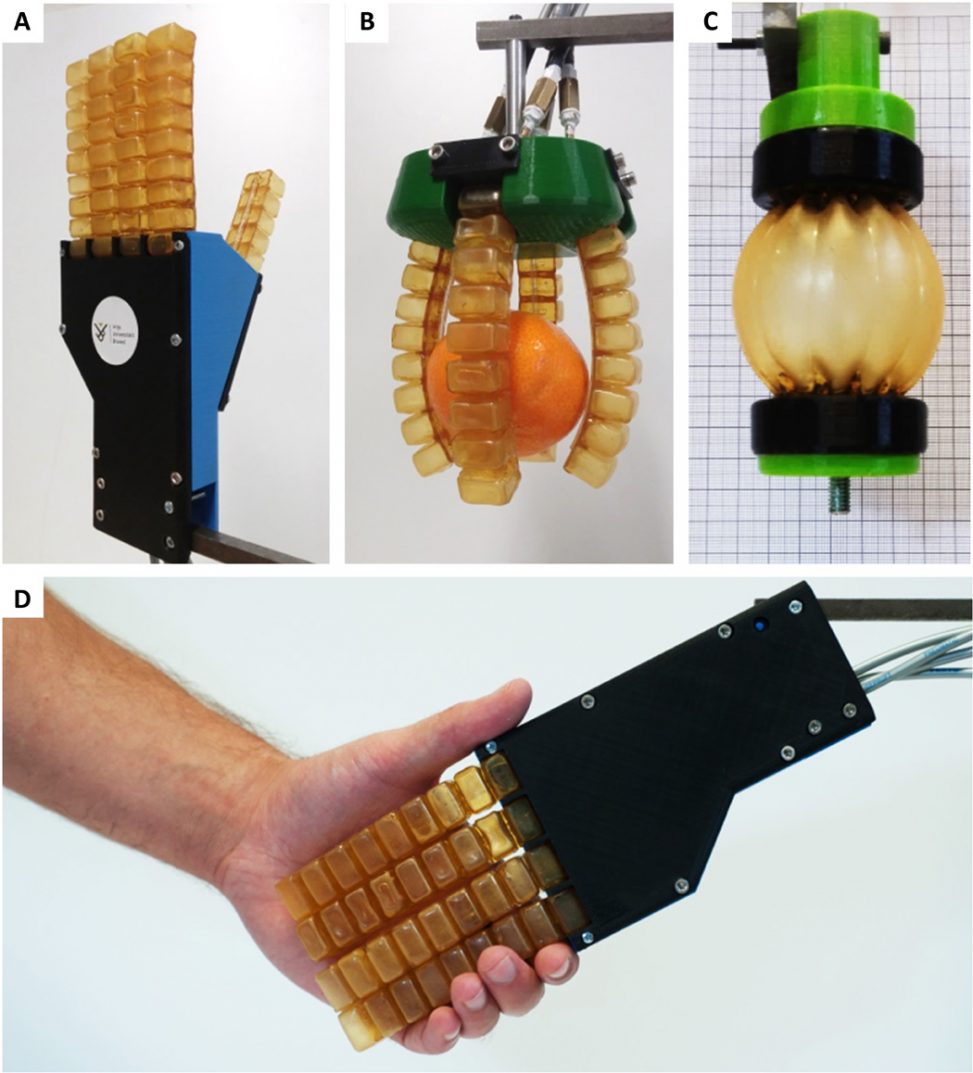

Soft Robotic Hands

Designed to absorb shocks and protect against mechanical impacts.

https://www.science.org/doi/10.1126/scirobotics.aan4268

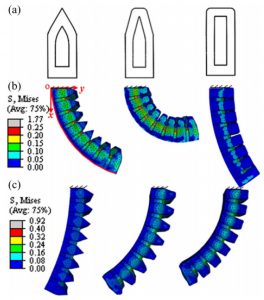

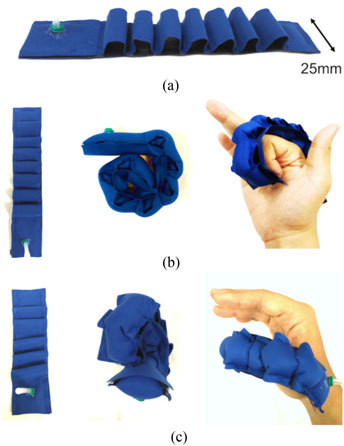

Fabric-Based Bidirectional Soft Robotic Glove

The glove provides both active finger flexion and extension for hand assistance and rehabilitative training.

- Fabric-based actuators that are fabricated by heat press and ultrasonic welding of flexible thermoplastic polyurethane-coated fabrics.

- Compared to other elastomeric-based actuators, able to achieve smaller bend radius and generate sufficient force and torque to assist in both finger flexion and extension at lower air pressure.

Sticky Actuators

Leave a Reply

You must be logged in to post a comment.