https://www.archdaily.com/879626/minima-maxima-marc-fornes-theverymany

Marc Fornes’ parametric pavilion, entitled “MINIMA|MAXIMA” is a 2017 project created by the research collective THEVERYMANY for the 2017 World Expo in Astana, Kazakhstan. This 43’ tall pavilion is designed using parametric architecture techniques including Rhinoscripting. Not only does Grasshopper (the generative modeling tool in the software Rhino) allow one to easily manipulate dimensions and shapes as well as the size of the individual panels, it can be used in conjunction with Python to create more complex geometries. Although the sculptural piece consists of only curves, the individual pieces of ultra-thin material are all created as flat surfaces, and only when interconnected do they take on their curved form. Although the construction of the pavilion is similar to the construction process of carbon fiber assembly, the structure is made of 6mm thick sheets of aluminum, stacked together to make a sandwich of white, pink, and white. Fornes and his collaborators continue to develop their research regarding the material and assembly tchniques used in their pavilions and treat each structure as a research opportunity. The cutting-edge assembly techniques used by THEVERYMANY, as well as the uniquely thin yet self-supporting construction material, are two incredibly admirable aspects of the pavilion.

![[OLD SEMESTER] 15-104 • Introduction to Computing for Creative Practice](../../../../wp-content/uploads/2023/09/stop-banner.png)

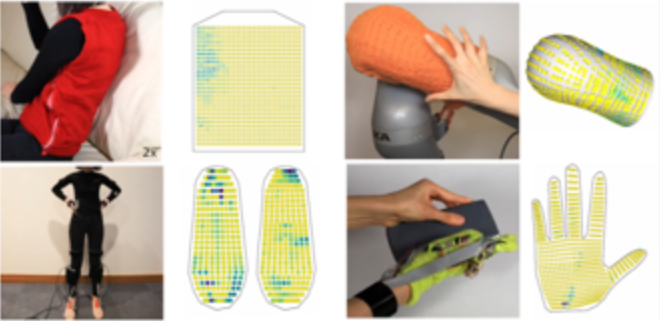

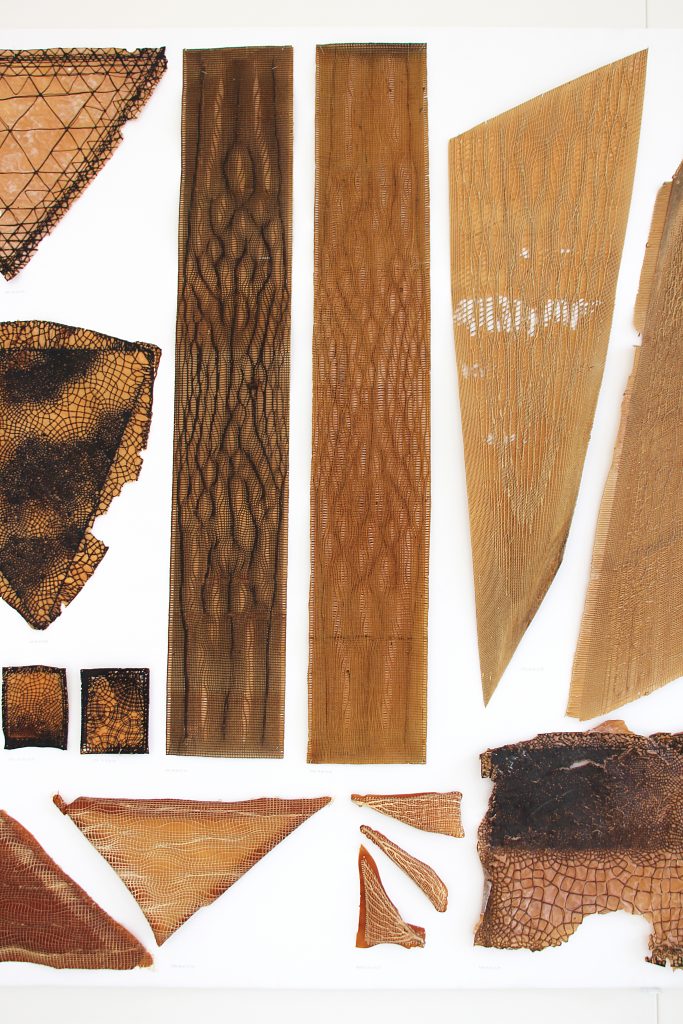

Collar Studies & Wrist Studies

Collar Studies & Wrist Studies