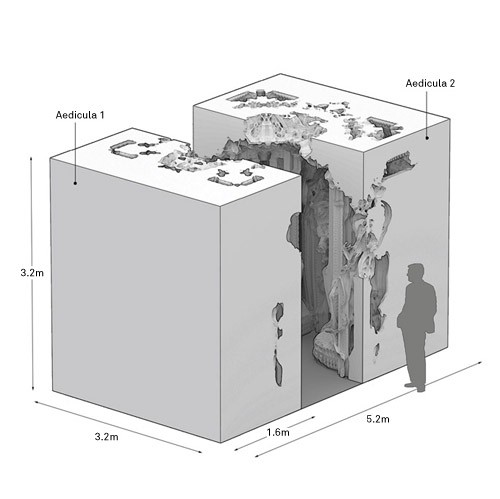

G3DP2 is a newly designed additive manufacturing technology that is 3D printed to be a revolutionary instability and optical implementations. This new glass takes away uncertain variables and gives users and designers greater control of material and experience. G3DP2 is able to be altered for users’ needs in terms of thermal control to molding. To advance a traditional material such as glass is easily overlooked because of the long satisfaction we’ve already had with the material. However, with this, there is greater “flow control, spatial accuracy and precision, and faster production rates with continuous deposition of up to 30kg of molten glass”.

The algorithm and idea behind the new design and structure of G3DP2 are based on the preferences which are the manufacturing platform and structural system. The “geometric expression” is the column surface area, number of lobes, and the turning radius of the printer. A lighting system inside the column is also programmed to move with kaleidoscope-like patterns. The work of The Mediated Matter group is very similar to projects like this. They are inspired for natural design in nature and use computational design and various digital fabrication skills to mimic natural patterns and processes. G3DP2 is an accurate depiction of The Mediated Matter group’s goals and focus.

![[OLD FALL 2020] 15-104 • Introduction to Computing for Creative Practice](../../../../wp-content/uploads/2021/09/stop-banner.png)