John Henley; 15-104 section D.

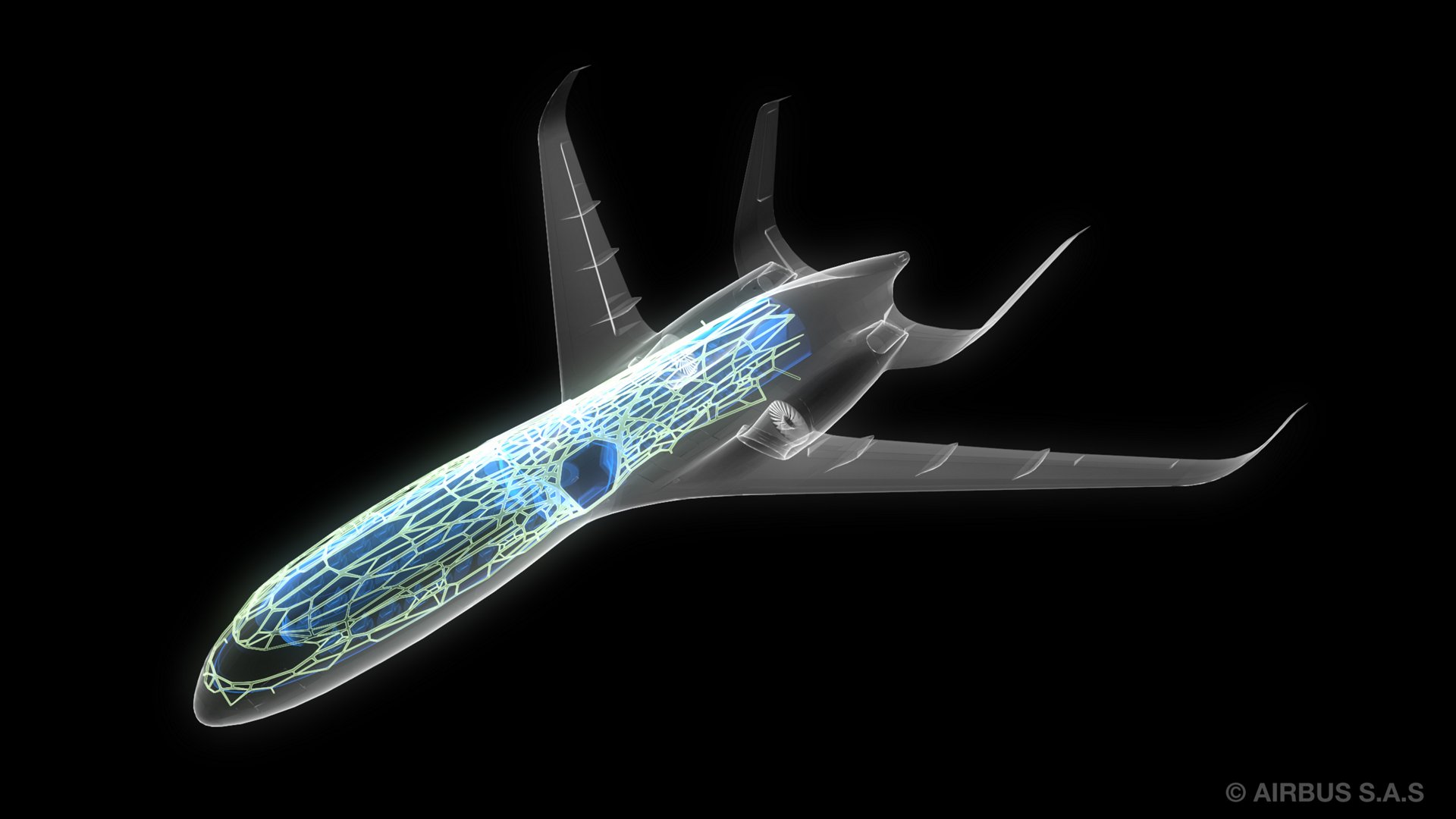

One of my biggest areas of interest in the world industrial design is biophilic design, or designs based off the natural world. A project that combines both generative design and biophilic design that I admire is the Airbus A320 bionic-partition. In 2016, Airbus developed algorithms based on the growth patterns of slime mold to create a new partition dividing the galley from the passenger cabin. The design mimics the single-cell organism’s organic cellular growing structure to create a material that is significantly lighter weight than the previous design. This new design reduces the weight by 55% due to the use of empty spaces evident between cells. In turn, because the aircraft is significantly lighter weight, Airbus claims it can save 465,000 metric tons of CO2 emissions per year. This new design approach is the future–using organic, biophilic-inspired designs in tandem with computer generated production to make the artificial world more efficient and sustainable.

Link to work: Pioneering bionic 3D printing – Company – Airbus

![[OLD SEMESTER] 15-104 • Introduction to Computing for Creative Practice](../../../../wp-content/uploads/2023/09/stop-banner.png)