Benjamin Dillenburger & Michael Hansmeyer’s “Digital Grotesque” / 2013, 2017

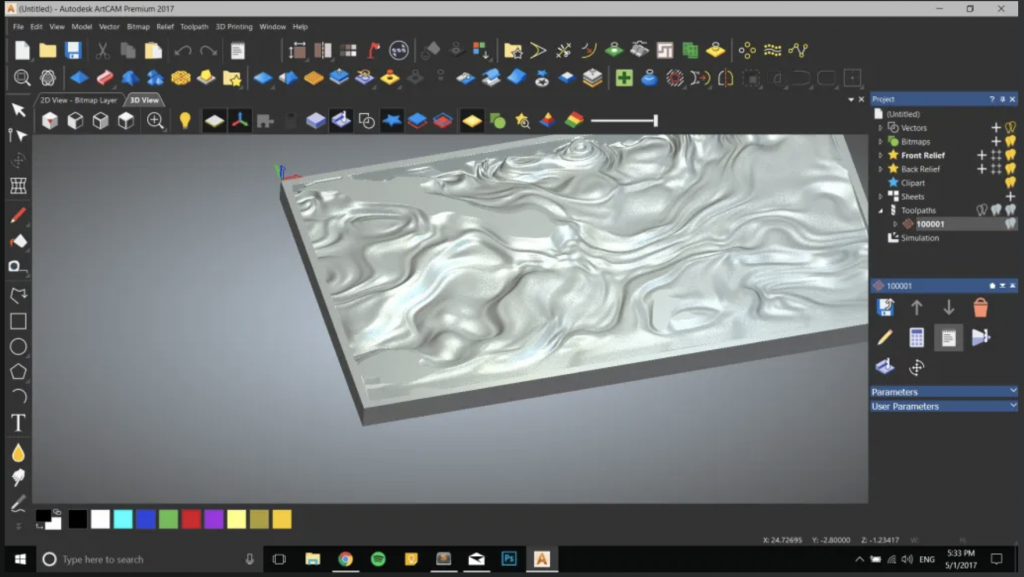

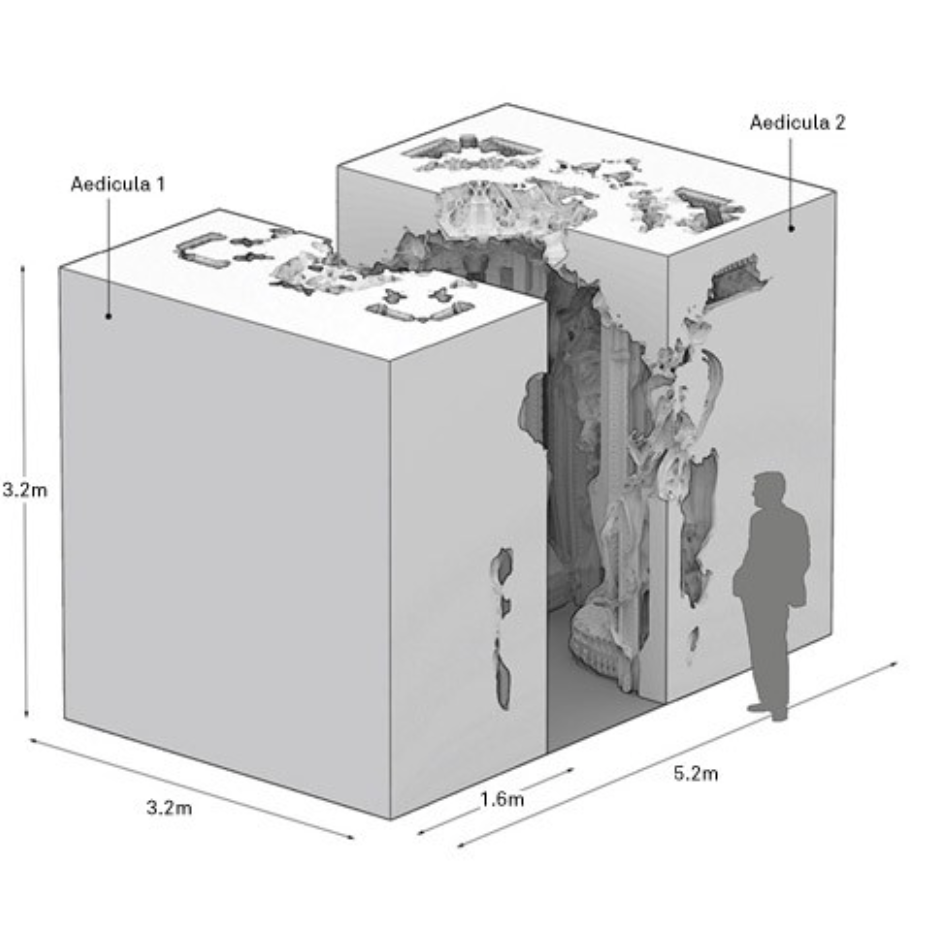

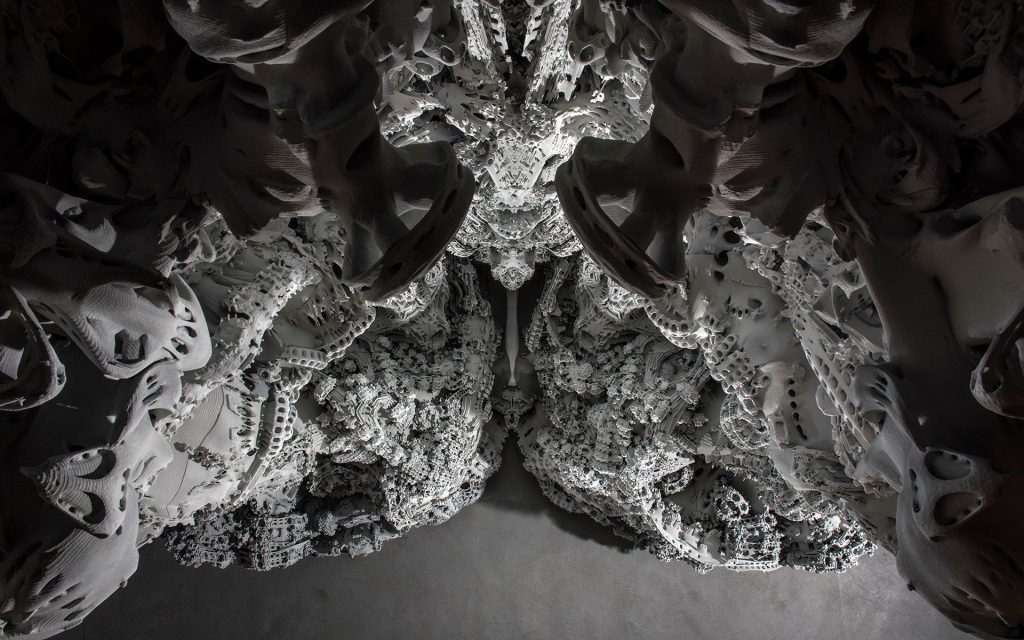

Digital Grotesque is made up of two full-size grottos that were 3D printed out of sandstone. It is a highly ornamented structure that was designed by algorithms, depicting how new technology is leading to radical changes in architectural design, and Digital Grotesque demonstrates this by taking this new technology to a scale never done before – truly life-sized. What I find admirable is the absolute intricacy of each crevice in this piece. The work is a 3.2-meter-high, 16 square meters long room, and is crammed full of minute details that stand between chaos and order.

Nothing can make this project any more perfect than it already is. It suggests an unimagined richness that at a glance can be overwhelming, and all the viewers can do is marvel, become curious and bewildered. One “flaw” that could be said about this piece is the seams between each 3D printed section, but I actually enjoy seeing the seams as a viewer because it’s a reminder of where this was initially conceived from; it’s not pretending to be built from stone or marble, it’s accepting its 3D printed quality. I applaud the creators who perfectly executed the concept full of juxtaposition: complexity yet reductionism, chaos and order, natural and artificial, foreign and familiar through its architectural design, composition, and geometric processes.

This project was reminiscent towards the Church of Sagrada Familia by Spanish architect Antonio Gaudi, and the artists are architects, programmers, and professors who are passionate about exploring the vast opportunities that computation applications can affect design and fabrication of architectural forms.

![[OLD FALL 2019] 15-104 • Introduction to Computing for Creative Practice](../../../../wp-content/uploads/2020/08/stop-banner.png)