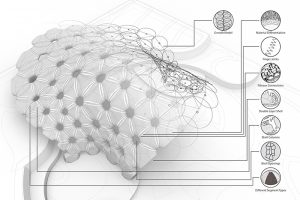

The institute of Computational Design (ICD) and the institute of Building Structures and Structural Design (ITKE) make Biomimetic Investigation into Shell Structures every year.

It is a holistic process in which the design is based on nature patterns, and the fabrication is made with Robotics arms.

The pavilion is the first of its kind to employ industrial sewing of wood elements on an architectural scale. It is part of a successful series of research pavilions which showcase the potential of computational design, simulation and fabrication processes in architecture.

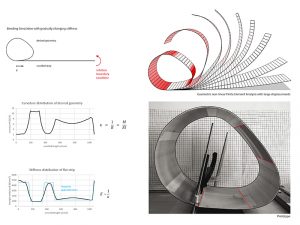

Based on both the biological principles as well as the material characteristics, the material system was developed as a double-layered structure similar to the secondary growth in sand dollars. The building elements consist of extremely thin wood strips. Instrumentalising the anisotropy of wood, these strips are custom-laminated so that the grain direction and thickness corresponds with the differentiated stiffness required to form parts with varying radii.

This project explores robotic sewing to not only join the individually bent plywood strips that form a segment, but also to prevent potential delamination. An industrial robot is employed for both assisting during the assembly and bending of the strips that make up one elements, and then locking the pre-assembled segment in shape by sewing them with a stationary industrial sewing machine. During fabrication the robot first moves the segment through the sewing machine so that the strips are connected.

This type of project falls into the pure research and innovative morphogenetic design based architecture in which the generation of the geometry follows an Agent Based System in which some growing rules are applied.

![[OLD FALL 2017] 15-104 • Introduction to Computing for Creative Practice](wp-content/uploads/2020/08/stop-banner.png)