My first encounter with Madeline Gannon’s project helped me think about things from another perspective. Can this organic and hand-made like wearable decoration be made by computational digital fabrication? Watching Gannon’s video, I was attracted by this combination. Exploring even deeper, I found many similar ideas where digital fabrication and computational algorithms are used to produce wearable and fashionable objects. One project that I really like is the “Kinematics Dress” by Nervous System. Jessica Rosenkrantz and Jesse Louis-Rosenberg, which is also called as “Nervous System”, have been doing highly influential work in the computational design of constructing decorative objects and garments.

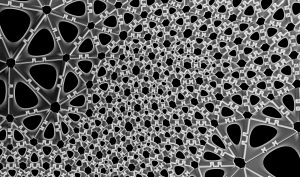

The Kinematics Dress is a technical achievement made by a 3D-printed garment to satisfy people’s needs of wearing a dress made out of current technology that is comfortable and durable. The Kinematics Dress is fabricated in nylon by 3D printing with Selection Laser Sintering. The first idea of the project is to make a necklace where the necklace is printed flat and can be folded later. The object will be made in computer code relating to kinematics algorithms first and then printed in a 3D printer.

The Nervous System intends the move from assembling all little pieces and construct a larger piece to making a smart material that will self-assemble itself. They start with computational folding and simulation to construct the dress in one piece. They then create a large object of a 3d scanned person that is larger than the 3d printer and then fold to suit the fabrication. Then, when taking out of the machine, the dress gets unfold. The final presentation of the dress is hard material connected with softer connections where they link with each other and can move freely. I really admire this project as it combines engineering and science with design and fabrication. It presents me with a bigger idea that opens up more possibilities to create garments with today’s technology.

![[OLD FALL 2017] 15-104 • Introduction to Computing for Creative Practice](wp-content/uploads/2020/08/stop-banner.png)