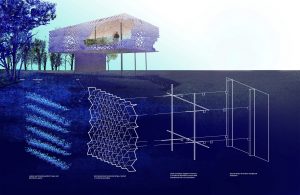

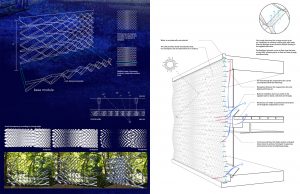

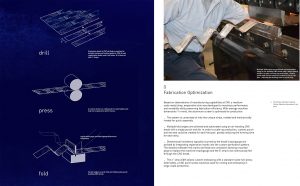

Evaporative Folding by Jeana Ripple (project architect), Ryan Lewandowski and Hossein Haj-Harriri + Mehdi Sadaat (consultant) uses computational techniques to customize the production of aluminum modules that creates an effective facade for evaporative cooling for houses in hot and dry climates. By optimizing material properties and manufacturing processes for aluminum, the team was able to generate an effective “cooling” facade that is durable, mold-resistant and can also act as an passive solar heat gain element during the night. The computational processes in the project is used to determine location, size of holes that are then CNC into the aluminium panels to create the perforation pattern suited for the house in the specific location.

It is inspiring to see the possible elegant solutions that computational processes are allowing architects and engineers to address environmental issues. Not only the project is successful in demonstrating what computational fabrication can do for the construction industry, it also shows that architects can design smarter buildings that are more energy efficient.

(image source: http://ripplearchitecture.com/Evaporative-Skin)

![[OLD FALL 2017] 15-104 • Introduction to Computing for Creative Practice](wp-content/uploads/2020/08/stop-banner.png)