Alka Cappellazzo is an artist and creative coder whose body of work seems to center around code-based animations. She doesn’t have a website, or any interviews and it was generally pretty difficult to find information regarding her. In a way she seems like the type of artist who likes to step out of the spotlight and let her work take center-stage for those who are interested in it. From what I was able to find however, I can say that she is currently based out of Italy and graduated from the Brera Academy of Fine Arts with degrees in New Art Technologies and Network Medias. She is also the current vice-president and co-founder of Invalid Code – an Italy based collective of “artists and programmers born to explore and spread the potential of the code.”

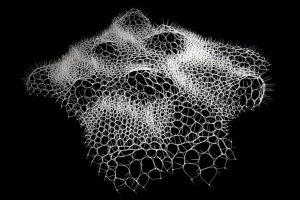

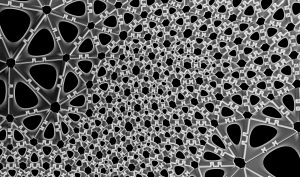

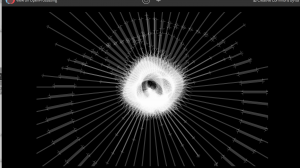

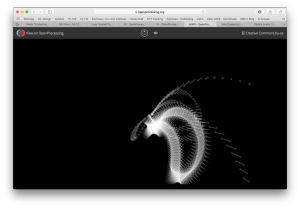

I want to take the time to talk about a body of work of hers, as opposed to an individual work, the series is called White Transparency and consists of a variety of animations or static images which are repetitions of graphics creating an ornamental and visually intriguing design. These patterns cleanly represent her interest in exploring the repetition of images and patterns in nature through the medium of code. Using Processing to facilitate these designs, she frequently codes these patterns while including random and noise functions so as to get some real/interesting or unexpected designs, similar to the unpredictability that nature holds with code. She also makes sure to make the code available to the audience, as she believes that code is something to be shared and expanded upon instead of huddled away and to be jealous of.

Below I am including some links to the processing pieces in addition to screenshots because I believe they are better experienced in real-time than seen in a still image.

White Transparency IV Link https://www.openprocessing.org/sketch/187998/embed/?width640&height=480&border=true

White Transparency II Link https://www.openprocessing.org/sketch/173726/embed/?width=640&height=480&border=true

![[OLD FALL 2017] 15-104 • Introduction to Computing for Creative Practice](../../wp-content/uploads/2020/08/stop-banner.png)